Introduction

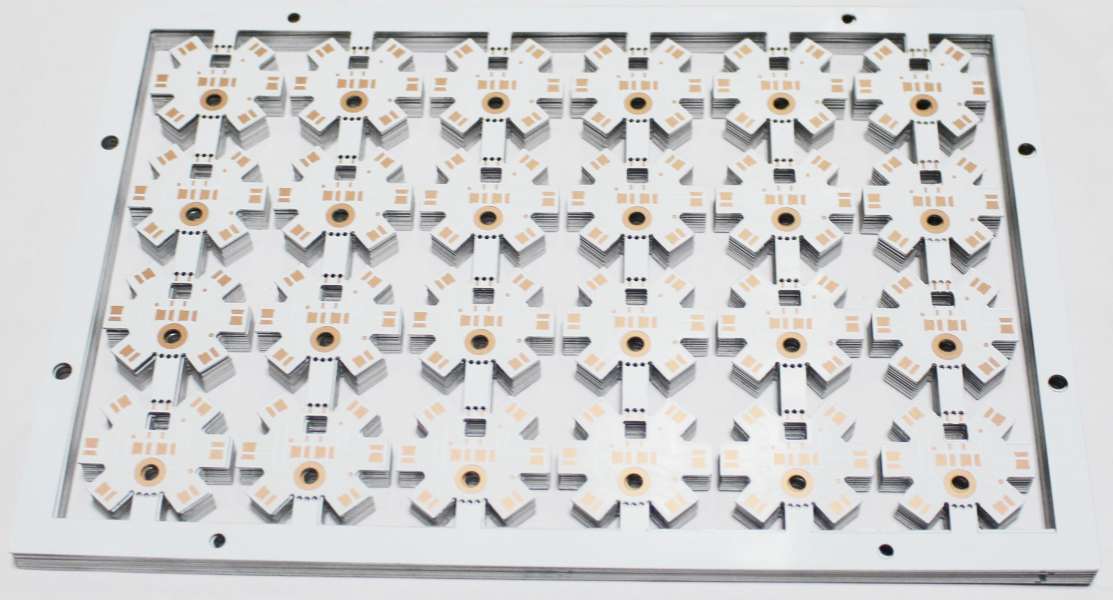

The LED lighting industry has seen massive growth in recent years driven by the energy efficiency, long life span, and design flexibility of LED technology. Critical to the LED system is the printed circuit board (PCB) which provides the platform to mount LEDs and other components as well as electrical connectivity. As the demand for LED lighting grows globally, a thriving ecosystem of PCB manufacturers has emerged to cater to the requirements of LED luminaire producers.

This article ranks the top 15 LED PCB manufacturers worldwide who have distinguished themselves based on factors like technology expertise, production capabilities, service quality and global footprint.

Top 15 LED PCB Manufacturers

1. RayMing Technology

Founded in 2005, Rayming is headquartered in Suzhou, China and has additional manufacturing bases in Vietnam and Serbia. With over 1800 employees globally, the company offers the full spectrum of PCB technologies including HDI, multilayer, aluminum boards, IMS substrates and flexible PCBs tailored to LED applications.

Rayming provides specialized LED PCB solutions covering applications like street lighting, stadium lighting, office lighting and more. The company has worked with major LED lighting brands worldwide and 75% of its revenue comes from overseas markets. Its annual production capacity exceeds $500 million.

The company’s global expertise in LED PCBs, strong R&D and manufacturing capabilities make Rayming the top LED PCB manufacturer worldwide.

2. Multek

Multek, a subsidiary of Taiwan’s Multi-Fineline Electronix (MFLEX), is a leading manufacturer of rigid, flexible and rigid-flex PCBs and value-added assemblies. Based in Zhuhai, China, Multek leverages its LCP-based circuit technology to produce high-reliability LED PCBs meeting thermal management and functional integration demands of LED lighting applications.

With advanced R&D and an expert engineering team, Multek provides specialized solutions for high brightness LEDs used in architectural lighting, entertainment lighting and signage. The company serves a global high-tech customer base with manufacturing sites across North America and Asia.

3. AT&S

Headquartered in Austria, AT&S has manufacturing plants in China, India and Korea and employs around 11,000 people. The company manufactures high-end PCBs for applications ranging from home appliances to medical devices.

In LED lighting, AT&S focuses on metal core PCBs which provide outstanding thermal performance required for high luminosity LEDs. Their solutions are widely used in streetlights, automotive lighting and high-power architectural lighting. The company offers specialized thermal analysis and thermal management design services for LED applications.

4. Unimicron

Based in Taiwan with production facilities in China and Germany, Unimicron is a global manufacturer of PCBs and IC substrates. It is a long-term supplier of LED PCBs to many leading solid-state lighting providers using technologies like high-density interconnect (HDI) and any-layer PCBs.

With a focus on quality and precision manufacturing, Unimicron provides PCB solutions tailored to LED lighting needs ranging from high power street lights and flood lights to portable LED luminaires. Their offerings cover single sided, double sided and multilayer PCB configurations based on design requirements.

5. Tripod Technology

Founded in 1990 and headquartered in Taiwan, Tripod manufactures PCBs for a wide range of end products including LED lighting. The company specializes in high-density interconnect (HDI) PCBs which are well suited for LED lighting applications due to their capability to accommodate dense component layouts in limited space.

Tripod’s offerings cover single-sided, double-sided, multilayer and flexible PCBs incorporating the latest technologies for LED luminaire manufacturers. Their global presence across Taiwan, China, Korea and USA enables them to support customers worldwide.

6. Zhen Ding Technology

Zhen Ding Tech, headquartered in Taiwan, provides advanced PCB solutions catering to 5G, automotive, IoT and clean energy industries including LED lighting. Their product offerings cover the full spectrum of PCB technologies – from double-sided to 10+ layer multilayer PCBs.

The company’s specialized LED PCBs are widely used in bulbs, tube lights, panels, street lights, horticultural lights and grow lights. With stringent quality control and RoHS compliance, Zhen Ding supplies LED PCBs globally and continues to grow its production capacity to meet market demand.

7. IBIDEN

IBIDEN is a Japanese company that manufactures diverse PCB products ranging from IC substrates to rigid multilayer boards. Through its Photo-Imageable Coverlay (PIC) technology, IBIDEN caters to high-density LED mounting applications.

IBIDEN’s LED PCB offering includes solutions for high power LEDs used in lighting for homes, offices, commercial facilities and industries. Their global production facilities and quality focus makes them a preferred LED PCB partner for major lighting brands.

8. CMK Corporation

CMK Corporation is a Japanese manufacturer of PCBs for a wide spectrum of electronics products. For the LED market, they offer 1-sided to 6-layer PCB solutions to address different application requirements in terms of component density, thermal performance and cost.

The company provides LED PCBs in high volumes at competitive price points while meeting the quality and reliability standards expected by Japanese firms. CMK leverages its technical expertise in PCB manufacturing to develop cost-optimized solutions specifically tailored to LED luminaire needs.

9. Nan Ya PCB Co

Part of the large Nan Ya plastics conglomerate in Taiwan, Nan Ya PCB is an established manufacturer of rigid, flexible and HDI PCBs since the 1970s. The company manufactures a wide range of PCB types for LED lighting applications including single-sided, double-sided, multilayer rigid boards as well as flexible PCBs.

With advanced process technologies and extensive LED domain knowledge, Nan Ya partners with LED luminaire producers to create customized PCB solutions that optimize for cost, thermals, reliability and manufacturability. Their large production capacities enable them to serve high volume LED lighting customers worldwide.

10. Shengyi Technology

Shengyi Technology Co. Ltd produces a variety of PCB products widely used in different types of LED luminaires and lighting. Headquartered in China, the company provides cost-competitive, high-quality PCBs in large volumes leveraging fully automated manufacturing lines and lean production capabilities.

Their offerings for LED applications cover single, double and multilayer PCBs which can be customized based on specific LED power, thermal requirements and luminaire mechanical design factors. Their extensive LED lighting domain expertise makes them a trusted partner for LED luminaire manufacturers worldwide.

11. Elite Material Co

Elite Material Co., Ltd. based in Taiwan provides specialized PCB solutions for LED signage, outdoor displays and lighting applications since 1996. Their product portfolio includes single-sided, double-sided, multilayer, aluminum base, flexible and rigid-flex LED PCBs.

The company focuses on high-quality manufacturing and advanced process technologies to produce PCBs tailored to high-power LED requirements. With a strong R&D team and customer partnerships, they continue to drive LED PCB innovations for next-generation lighting and display products.

12. Ascent Circuits

Based out of the United States, Ascent Circuits provides PCB design, fabrication and assembly services for various industries. For LED lighting, they produce custom double-sided, multilayer, flexible and rigid-flex boards catering to the design needs of luminaire manufacturers.

With experts specializing in thermal design and LED technology, Ascent helps optimize PCB layouts for LED arrays to manage heat dissipation and ensure long LED life. Their domestic US production and network of global partners enables them to support the LED industry worldwide.

13. Shennan Circuits

Shennan Circuits is a leading Chinese PCB manufacturer established in 1989 with factories across China to offer a variety of PCB and assembly solutions. Their offerings for the LED industry span across single sided, double sided and multilayer PCB designs tailored for LED bulb, panel, downlight and streetlight applications.

Their high-volume production capabilities, competitive pricing and experience supplying LED PCBs to major brands makes them one of the top choices for luminaire producers seeking China-based PCB partners. They are ISO-9001 certified and can produce PCBs compliant with international quality standards.

14. Amitron Corporation

Amitron is a US-based PCB manufacturer catering to the military, telecom, industrial, and consumer electronics markets. The company manufactures LED PCBs compliant to IPC standards suited for indoor and outdoor commercial lighting applications. Their key PCB technologies offered for LED applications include multilayers, flex-rigid boards and thermal core PCBs.

Amitron also provides specialized LED heatsink manufacturing service which allows effective thermal management for high power LEDs – critical in lighting applications. Their capabilities spanning PCB fabrication, assembly and heatsink manufacture makes them a reliable partner for the LED industry.

15. Wus Printed Circuit Co

Founded in 1998, Wus Printed Circuit is a major Chinese PCB and assembly manufacturer serving diverse markets including LED lighting. The company offers the spectrum of PCB technologies relevant to LED applications including single-sided, double-sided, multilayer, aluminum PCBs and flex-rigid boards.

Wus PCB’s comprehensive solutions for LED lighting cater to the design requirements of various luminaires including LED bulbs, panel lights, down lights, spot lights and street lights. Their cost-competitive solutions combined with technology expertise makes them an attractive Chinese PCB partner for LED firms.

Comparison of the Top LED PCB Manufacturers

| Manufacturer | Location | Key Technologies | Capabilities |

|---|---|---|---|

| Rayming Technology | China | HDI, multilayer, thermal boards | Leading technology, scale, global footprint |

| Multek | China | LCP-based PCBs | Advanced R&D, high-reliability solutions |

| AT&S | Austria | Metal core PCBs | Specialized thermal analysis services |

| Unimicron | Taiwan | HDI, multilayer | Precision, quality focused manufacturing |

| Tripod Technology | Taiwan | HDI PCBs | High-density PCB solutions |

| Zhen Ding Tech | Taiwan | Multilayer PCBs | Stringent quality control and compliance |

| IBIDEN | Japan | PIC technology | High-density LED mounting, global facilities |

| CMK Corporation | Japan | 1- to 6-layer PCBs | Technically advanced, cost-optimized solutions |

| Nan Ya PCB | Taiwan | Rigid, flex, multilayer PCBs | Extensive LED domain expertise |

| Shengyi Technology | China | Single, double, multilayer PCBs | High-volume, cost-competitive supplier |

| Elite Material | Taiwan | Rigid, flex, aluminum PCBs | Specialized solutions for LED signage and lighting |

| Ascent Circuits | USA | Multilayer, flex and rigid-flex PCBs | Thermal design optimization capabilities |

| Shennan Circuits | China | Double sided, multilayer PCBs | High-volume production for major LED brands |

| Amitron Corporation | USA | Multilayer, thermal core PCBs | PCB and heatsink manufacturing services |

| Wus Printed Circuit | China | Rigid, flex, aluminum PCBs | Cost-competitive, high-volume supplier |

How to Select the Right LED PCB Manufacturer?

Choosing the right PCB partner is critical when designing an LED luminaire. Here are some key criteria to consider during selection:

- Technical capabilities – Look for expertise in LED PCB technologies like metal core, thermal boards, HDI etc. related to your lighting application.

- LED domain experience – Choose a manufacturer with proven track record of supplying to LED firms rather than general PCB producers.

- Quality focus – Ensure they have design, manufacturing and testing practices focused on quality and reliability.

- Volume production – For high volumes, partner with companies having large manufacturing capacity and lean operations.

- Cost competitiveness – Evaluate quote vs value offered as well as capabilities to reduce cost through design and process optimization.

- Proximity – For faster logistics and engineering collaboration, consider manufacturers with production nearby.

- Compliance – Ensure the PCB supplier and their materials/processes meet required regulatory standards.

- Customer support – Look for responsive support during design, prototyping and ramp-up phases.

By carefully evaluating manufacturers based on these criteria, LED lighting firms can select the right strategic PCB partner to bring their products to market faster.

LED PCBs – Frequently Asked Questions

Q1. What are some key considerations for thermal management in LED PCBs?

Some effective thermal management techniques used in LED PCB design are:

- Use of thermal vias to conduct heat away from LEDs to inner or bottom layers

- Large copper planes on inner layers to spread heat

- Direct LED bonding to aluminum or copper PCB substrate

- Incorporating thick metallic thermal cores inside multilayer PCB sandwich

- Exposed thermal pads under high-power components

- Use of thermally conductive materials like ceramics and epoxies

Q2. How does LED PCB design vary for high power and low power applications?

High power LED lighting requires PCBs designed for higher current, thermal dissipation and reliability considerations:

- Thicker copper layers are used – 2oz, 3oz instead of standard 1oz

- Minimum trace widths increased for high current capacity

- Larger clearances and creepage distances for high voltage designs

- Materials like polyimide and LCP used for temperature tolerance

- Aluminum or metal core PCBs used for heat spreading

For low power LEDs, conventional FR4 PCBs with 1oz copper are sufficient in many cases.

Q3. What are the main PCB fabrication processes used in LED PCB manufacturing?

Some key PCB processes used in fabrication of LED PCBs:

- Lamination – building multilayer board by pressing stacked layers

- Drilling – creating holes for electrical interconnection between layers

- Metallization – electroplating copper on drilled holes for conductivity

- Photolithography – selectively etching copper to form patterned traces

- Solder mask – insulating solderable areas from oxidation and short circuits

- Silkscreen – printing visible labels, markings and symbols on PCB

- Surface finish – applying coatings like solder, gold, or tin on pads

- Electrical testing – ensuring conductivity, insulation properties and function

- Assembly – placement and soldering of LED and other components

Q4. What are the key tests performed on LED PCBs?

Some typical tests performed to ensure quality of LED PCBs:

- Net connectivity – validates electrical connections match circuit netlist

- Insulation resistance – ensures insulation between circuits; no short circuits

- Hipot testing – verifies dielectric strength of insulation materials

- Thermal stress – subjects PCB to temperature cycling over range

- Power cycling – switches power on/off repeatedly, checking for failures

- Vibration and shock tests – confirms mechanical integrity

- Solderability – verifies pads/leads are solderable for component mounting

- AOI inspection – automated optical inspection of solder joints, markings etc.

- Functional testing – validates LED and board work correctly when energized

Q5. What design for manufacturing guidelines help make LED PCBs production-friendly?

Some ways LED PCB layouts can be designed to ease manufacturing:

- Allow adequate spacing between components for fabrication and assembly

- Minimize density variations across PCB to enable uniform etchant access

- Place connectors, switches and tall components first to reduce shadowing

- Avoid traces running between closely spaced pads; use dog bone patterns

- Minimize use of microvias which reduce drilling tool life

- Ensure trace widths and spacings conform to fabrication capabilities

- Use standard PCB thickness. Custom thicknesses increase cost.

- Minimize holes size variations; use few different drill sizes if possible

- Mark locations requiring special PCB finish, material, or tolerances