SMT

-

Read more: How to Choose Quick Turn PCB Assembly Manufactuer

Read more: How to Choose Quick Turn PCB Assembly ManufactuerIntroduction to Quick Turn PCB Assembly Quick turn printed circuit board (PCB) assembly refers to the rapid manufacturing of assembled PCBs on demand within a short time frame. Typically, quick turn assembly times range from 24 hours to 10 days. This accelerated service caters to prototyping needs or short production … Read more

-

Read more: SMT Reflow Ovens: Manufacturers, Cost and Temperature Range

Read more: SMT Reflow Ovens: Manufacturers, Cost and Temperature RangeReflow ovens are an essential piece of equipment for electronics manufacturing using surface mount technology (SMT). They use precise heating profiles to melt solder paste and attach surface mount components like resistors, capacitors, and integrated circuits to printed circuit boards (PCBs). This article provides an overview of leading reflow oven … Read more

-

What Is Reflow Soldering?

Posted by

–

Read more: What Is Reflow Soldering?

Read more: What Is Reflow Soldering?Reflow soldering refers to a process used to form electrical interconnections between component leads or pads on a printed circuit board (PCB) by applying solder alone without additional hand soldering. In reflow, solder paste containing powdered solder alloy and flux is first screen printed or dispensed onto pads. Components are … Read more

-

Best 6 PCB Assembly Manufacturers in California

Posted by

–

Read more: Best 6 PCB Assembly Manufacturers in California

Read more: Best 6 PCB Assembly Manufacturers in CaliforniaCalifornia has one of the highest concentrations of electronic product companies in the world. Many global tech leaders like Apple, Intel, and HP were founded in California and continue to shape the consumer electronics landscape with cutting edge technologies. This creates massive local demand for PCB assembly partners able to … Read more

-

What is Small Batch PCB Assembly ?

Posted by

–

Read more: What is Small Batch PCB Assembly ?

Read more: What is Small Batch PCB Assembly ?Small batch PCB assembly refers to the manufacturing of printed circuit boards (PCBs) in relatively small quantities, typically ranging from 10 to 1,000 boards per order. It meets the needs of engineers, makers, and small companies who require fully assembled PCBs but do not need the large volumes required to … Read more

-

Top 15 SMD Rework Stations In 2024

Posted by

–

Read more: Top 15 SMD Rework Stations In 2024

Read more: Top 15 SMD Rework Stations In 2024Surface-mount device (SMD) rework stations have become essential tools for splicing component PCB repairs and engineering prototype iterations. This article reviews the top-rated SMD rework stations across various budget levels for hobbyist, education, and commercial/industrial usage. Overview of SMD Rework Stations SMD rework stations integrate controllable heat sources with arm/hand … Read more

-

What is SMT (Surface-mount technology )?

Posted by

–

Read more: What is SMT (Surface-mount technology )?

Read more: What is SMT (Surface-mount technology )?Surface-mount technology (SMT) refers to a method of electronically assembling printed circuit boards (PCBs) characterized by mounting electronic components directly onto the surface of PCBs rather than with wire leads passing through holes. First commercialized in the 1960s, SMT has revolutionized PCB manufacturing over the past decades enabling tremendous electronic … Read more

-

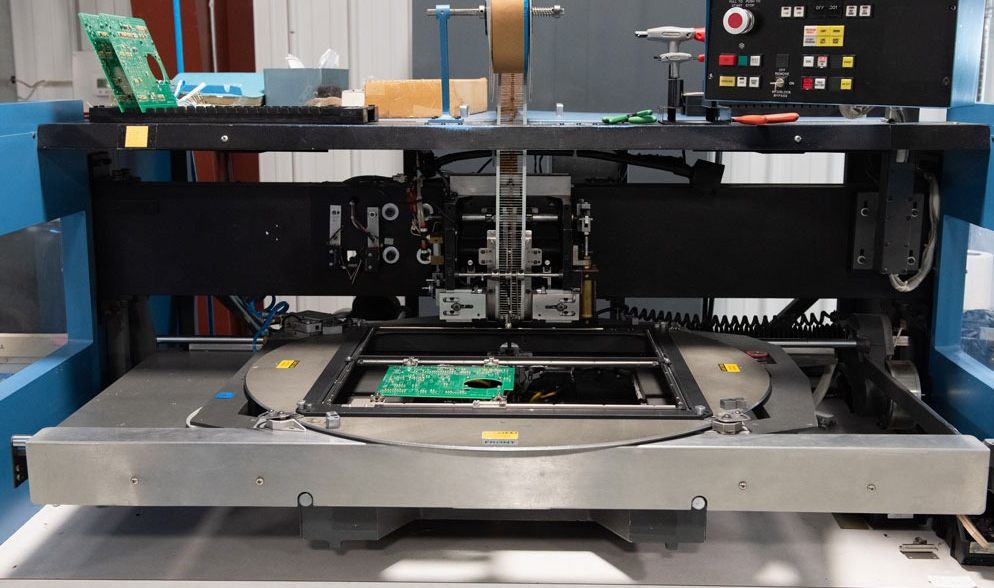

What is SMT Assembler?

Posted by

–

Read more: What is SMT Assembler?

Read more: What is SMT Assembler?A SMT assembler refers to a manufacturing machine designed to automate the placement and soldering of surface mount technology (SMT) electronic components onto printed circuit boards (PCBs). SMT assemblers, also known as SMT pick-and-place machines, help achieve high throughput assembly of the small devices that enable modern miniaturized electronics. Understanding … Read more

-

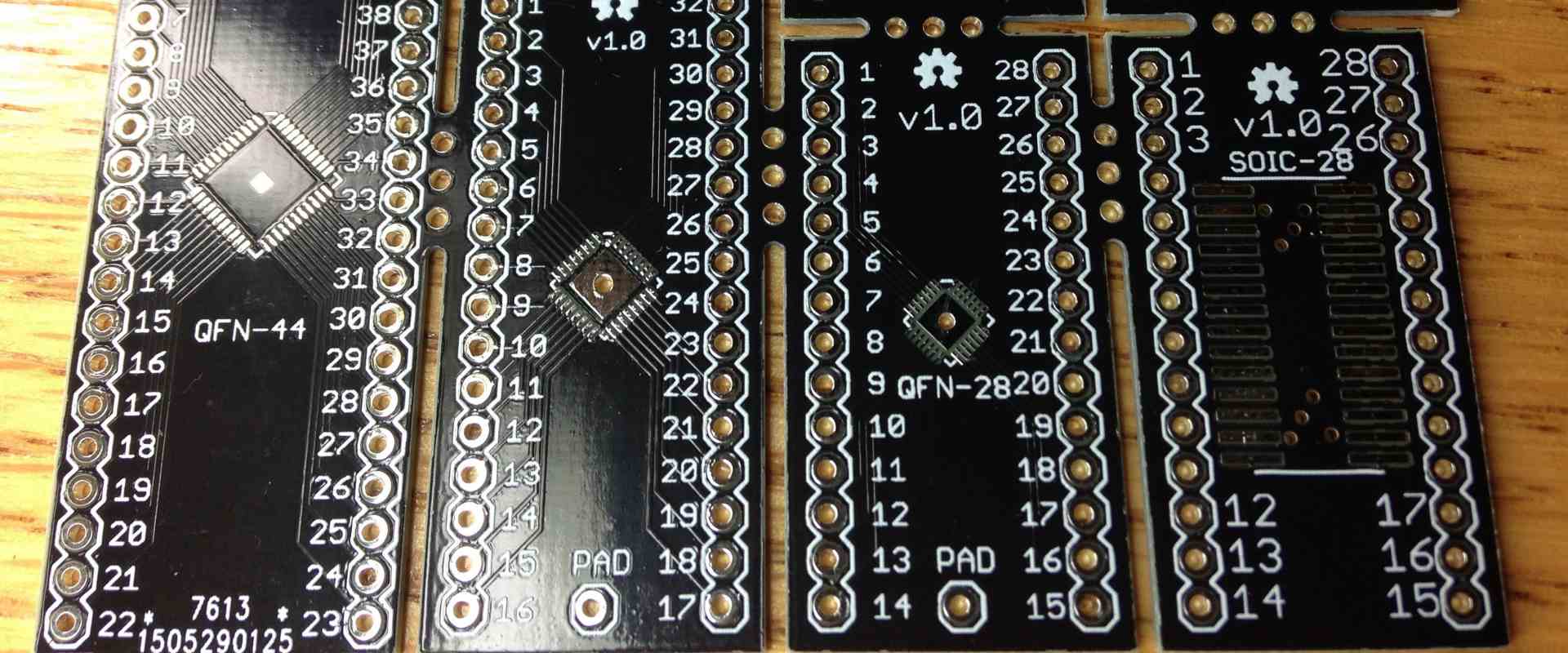

What is SMT Breakout Boards ?

Posted by

–

Read more: What is SMT Breakout Boards ?

Read more: What is SMT Breakout Boards ?A SMT breakout board refers to a small printed circuit board designed to convert the fine pitch of surface mount component terminals into wider through-hole pins or solder pads to facilitate prototyping, testing, and debugging. Breakout boards simplify integration with devices having dense ball grid arrays (BGAs), land grid arrays … Read more

-

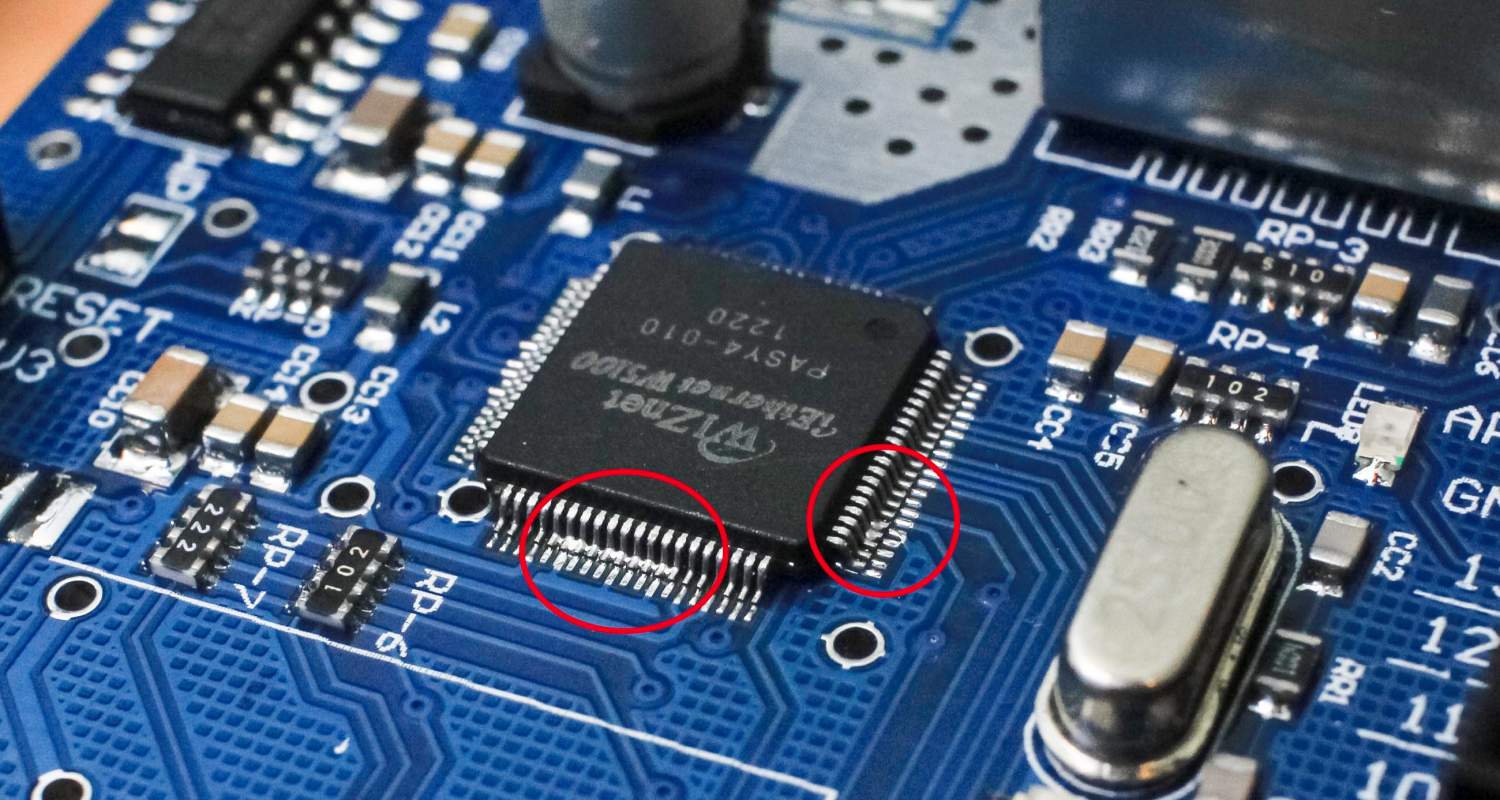

How Do You Prevent Solder Bridging?

Posted by

–

Read more: How Do You Prevent Solder Bridging?

Read more: How Do You Prevent Solder Bridging?What is Solder Bridging? Solder bridging refers to the unintended electrical connection created when solder forms between adjacent component pads, lands, terminals or conductors on a printed circuit board assembly. This phenomena occurs as a result of excess solder spreading out from a joint during reflow soldering operations. Capillary wetting … Read more

Recent Posts

- Understanding the PCB Burn-in Testing Process in PCB Manufacturing!

- Unlock the Potential of Embedded PCB Assemblies for Improving the Performance of Electronics Devices

- What are the Advantages of Custom Cable Assembly to meet your bespoke needs?

- What are the benefits and limitations of custom PCB boards?

- What are the benefits of Prototype PCB manufacturing and why is it important?

Categories

- 3D Guides 2,663

- Components 4

- Design 22

- Electronics 20

- PCB 125

- SMT 27

Tag Cloud

There’s no content to show here yet.