Introduction

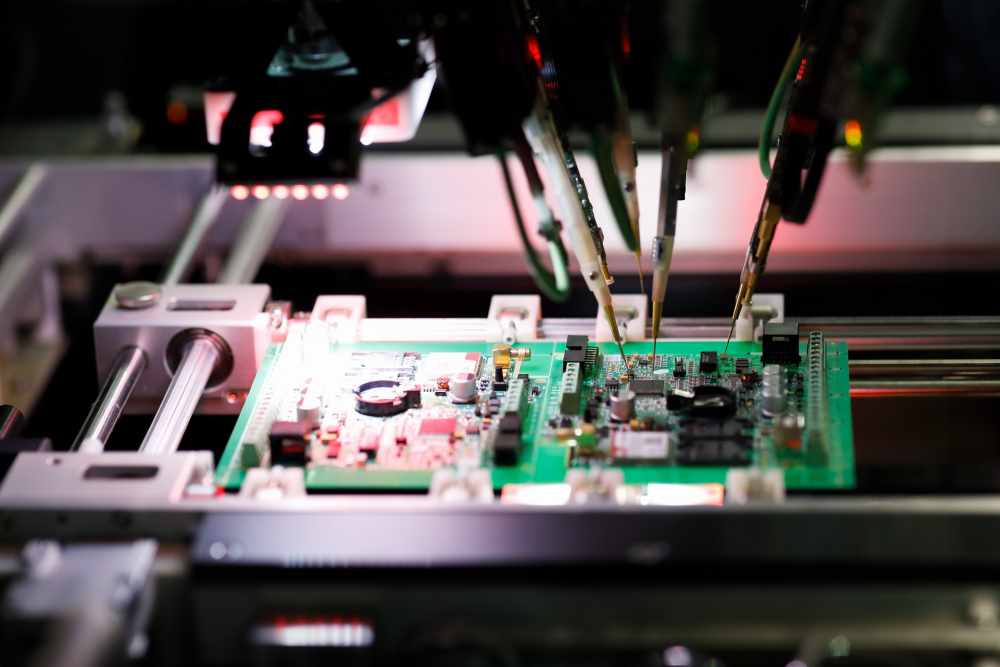

For prototyping and validating electronic designs quickly, having printed circuit boards (PCBs) assembled rapidly with a fast turnaround time is essential. This allows testing design iterations and modifications faster to accelerate product development.

China has established itself as the electronics manufacturing hub of the world, producing PCBs from prototype volumes to high volume mass production. This article examines the typical fast turnaround times achievable for PCB assembly in China and the key factors impacting it.

What is Considered Fast Turn PCB Assembly?

For most general circuit boards, the industry standard lead time is around 15 working days from order placement to delivery of assembled boards. The actual PCB fabrication only takes 3-5 days. Additional time is needed for shipping, assembly, testing and logistics.

However, for urgent prototyping needs, PCB assembly with much shorter turnaround times is required.

Fast turn PCB assembly typically refers to timescales of:

- 5-7 working days – Very fast build

- 8-10 working days – Fast build

- 11-14 working days – Expedited build

So fast turn implies cutting the standard 15 day lead time down to 10 days or ideally within a week. This is essential for minimizing product development cycles.

Capabilities of Chinese PCB Assembly Services

Thanks to the vast electronics supply chain and manufacturing infrastructure in China, most PCB assembly houses in the country can provide fast turn services with the following capabilities:

- PCB fabrication in as little as 24 hours

- Inventory of common components for rapid sourcing

- In-house assembly for quick SMT population

- Parallel workflows for engineering and production

- Local suppliers within China for fast component delivery

- On-site testing and inspection

- Local warehouses for prompt PCB shipping

By leveraging these capabilities, the fastest assembly time currently achievable is:

3-4 working days from order to delivery

This timeline is possible for simpler board designs using mostly common components that can be sourced quickly.

Key Factors Impacting Fast Turn Assembly Time

While 3-4 days is best case, several factors influence how quickly PCB assembly can actually be completed:

PCB Design Complexity

Simple 2 layer boards with SMT components can be assembled fastest. Complex boards with high component counts take longer.

Bill of Materials (BOM)

Common components that the assembler has in stock speed up the process. Long lead items require ordering and will delay build.

Component Location

Supply chains within China allow much faster component procurement compared to sourcing from distributors in US or Europe.

Assembly Technology

Automated SMT assembly is faster than manual assembly. Little manual intervention speeds up the process.

Testing Requirements

Extensive testing such as environmental stress screening or long functional tests increases lead time.

Order Quantity

Assembling a larger quantity batch together dilutes setup times for faster assembly per board.

Engineering Changes

Any design modifications or document revisions during the process introduce delays to update cadence.

Cost Impact of Fast Turn Assembly

Accelerated PCB assembly has cost impacts:

- Rush PCB fabrication charges

- Fees for expediting component procurement

- Additional resources needed for rapid assembly

- Overnight freight charges

- Requirement of local component inventory

- Potential for premium pricing from supply chain

This usually results in 30-50% higher cost for fast turn vs standard assembly. However, the time savings in prototyping often offset the incremental costs.

Methods to Further Reduce Assembly Lead Time

Additional techniques can shave off more time from PCB assembly:

- Have backup component suppliers in case of stockouts

- Pay for supplier inventory buffer stock for critical parts

- Submit Gerber files early for initial DFM analysis

- Prepay upfront for PCB fabrication and components

- Use manufacturability-proven reference designs

- Reduce testing to only essential items

- Pay extra for 1-day PCB fabrication

Careful planning is key to enable the fastest possible PCB assembly turnaround.

Lead Time Trends and Future Outlook

- As supply chains tighten and become more responsive to demand variation, lead times for components and boards will reduce further.

- More extensive use of automation, AI and advanced manufacturing techniques will increase production velocity.

- With more real-time order transparency and track-and-trace capabilities, delays can be identified sooner.

- Just-in-time manufacturing proliferation will enable fulfillment in under a week.

- On-demand production using local micro-factories and distributed inventory will allow near instant turnaround.

In the future, 1-2 day fast turn assembly may become commonplace for average orders thanks to lead time compression across the electronics supply chain.

Conclusion

Fast turnaround PCB assembly with timescales under a week enables rapid prototyping iterations for product development. This is especially critical for startups. Thanks to its extensive electronics ecosystem, China offers assembly services capable of delivering small batches of working boards in as little as 3-5 days. However, creating the infrastructure for responsive quick-turn requires investments and careful planning. For highest priority projects with compressed schedules, paying premium prices for fast turn services can provide substantial benefits by accelerating market introduction and product qualification. As supply chain agility and digitalization continue evolving, we can expect fast PCB assembly turnarounds to become the norm rather than the exception.

Key Takeaways

- Fast turn is considered PCB assembly in under 2 weeks, ideally within 5-7 days

- PCB fabrication in 24 hours along with overnight component delivery enables rapid assembly

- Simpler boards with common parts are quicker to assemble

- Localized supply chains are essential to enable fast turnaround

- Additional costs are incurred for expediting fabrication, parts and shipping

- Higher levels of supply chain visibility and coordination will fuel further lead time reductions

Suggestions for Fast Turn PCB Assembly

- Use an experienced assembly partner with proven quick-turn capabilities

- Keep initial designs simple – 2 layers, low component counts

- Reuse proven schematics and layouts where possible

- Check BOM for long lead time parts early

- Limit extended testing and inspection

- Be flexible on interim documentation and revision control

- Pay premium price for fastest turn if needed

- Plan for parallelizing or staggering builds of multiple iterations

With the right partner and efficient processes, fast turn PCB assembly enables rapid design verification and development acceleration.