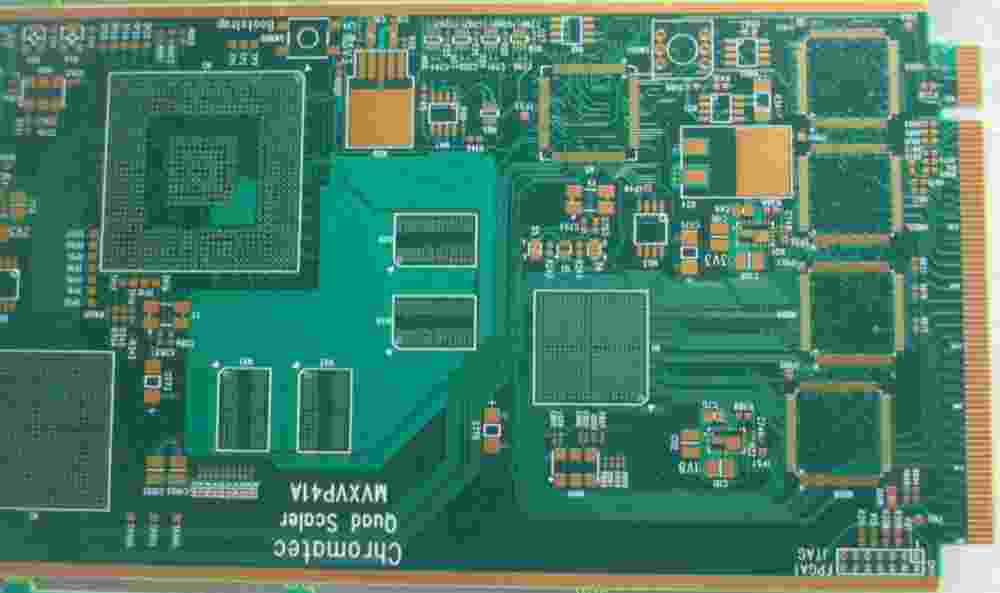

Printed circuit boards (PCBs) form the foundation of electronics, interconnecting components to enable functional devices and systems. Driven by surging demand from consumer electronics and automotive in particular, China has become the undisputed global leader in PCB production. Over half of the world’s PCBs are now manufactured in China.

Hundreds of PCB fabricators in China offer everything from prototype to extreme high volume manufacturing across an array of technologies. Here are 12 of the major and most reputable PCB manufacturers presently operating in China:

1. Shennan Circuits

- Headquarters: Shenzhen

- Founded: 1999

- Capabilities: PCB prototyping, high-volume SMT assembly

- Certifications: ISO 9001, ISO 14001, UL

- Industries served: telecom, industrial, medical, automotive

- Production capacity: Over 800,000 sqm of PCBs per month

2. RayMing Technology

- Headquarters: Suzhou

- Founded: 2001

- Capabilities: Rigid, flex, rigid-flex, metal core PCBs

- Certifications: ISO 9001, TS 16949, ISO 14001

- Industries served: Aerospace, automotive, medical, industrial

- Production capacity: Over 150,000 sqm of PCBs per month

3. Tripod Technology

- Headquarters: Xiamen

- Founded: 1992

- Capabilities: Rigid and flex PCB prototyping and production

- Certifications: ISO 9001, ISO 14001, TS 16949, UL

- Industries served: Automotive, telecom, industrial, consumer electronics

- Production capacity: Over 1.2 million sqm of PCBs per month

4. Multek Flexible Circuits

- Headquarters: Zhuhai

- Founded: 1991

- Capabilities: Rigid-flex, flexible circuits, HDI PCBs

- Certifications: ISO 9001, ISO 14001, ISO 13485, IATF 16949

- Industries served: Automotive, industrial, medical, aerospace

- Production capacity: Over 1.5 million sqm of PCBs per month

5. Zhen Ding Technology

- Headquarters: Dongguan

- Founded: 2002

- Capabilities: Multilayer, HDI, flex-rigid PCB fabrication

- Certifications: ISO 9001, ISO 14001, UL, TS 16949

- Industries served: Automotive, industrial, consumer electronics

- Production capacity: Over 800,000 sqm of PCBs per month

6. TTM Technologies

- Headquarters: Shanghai

- Founded: 1998

- Capabilities: Prototype and high-volume PCB production

- Certifications: ISO 9001, ISO 14001, ISO 13485, AS 9100

- Industries served: Aerospace, industrial, automotive, medical

- Production capacity: Over 3.5 million sqm of PCBs per month

7. AT&S China

- Headquarters: Shanghai

- Founded: 2007

- Capabilities: IC substrates, HDI PCBs, EMS

- Certifications: IATF 16949, AS 9100

- Industries served: Automotive, industrial, consumer electronics

- Production capacity: Nearly 2 million sqm of PCBs per month

8. Founder Technology

- Headquarters: Changzhou

- Founded: 2002

- Capabilities: High-volume rigid, flex, HDI PCBs

- Certifications: ISO 9001, ISO 14001, TS 16949

- Industries served: Telecom, automotive, industrial, medical

- Production capacity: Over 500,000 sqm of PCBs per month

9. Kingboard Laminates

- Headquarters: Guangdong

- Founded: 1988

- Capabilities: Specializes in laminates for high-frequency PCBs

- Certifications: ISO 9001, ISO 14001, TS 16949

- Industries served: Networking, communications, automotive

- Production capacity: Over 18 million sqm laminates per month

10. Ellington

- Headquarters: Shanghai

- Founded: 2005

- Capabilities: Rigid, flex, and rigid-flex PCBs

- Certifications: TS 16949, ISO 9001, UL

- Industries served: Automotive, industrial, consumer electronics

- Production capacity: Nearly 500,000 sqm of PCBs per month

11. CMK

- Headquarters: Jiangmen

- Founded: 2005

- Capabilities: Prototype and high-volume rigid PCB production

- Certifications: TS 16949, ISO 9001

- Industries served: Automotive, industrial, communications

- Production capacity: Approximately 600,000 sqm of PCBs per month

12. Tekra

- Headquarters: Shantou

- Founded: 1985

- Capabilities: Rigid, flex, rigid-flex PCBs

- Certifications: ISO 9001, ISO 14001

- Industries served: Industrial, communications, medical, automotive

- Production capacity: Over 120,000 sqm of PCBs per month

Why Manufacture PCBs in China?

There are several major advantages supporting China’s dominance as the leading global PCB manufacturing hub:

- Low Costs – Highly competitive pricing thanks to scaled infrastructure and labor economics

- Production Capacity – Massive capacity across tens of thousands of domestic PCB factories

- Technology – Constant investment in advanced equipment and processes

- Ecosystem – Comprehensive upstream and downstream supply chains

- Workforce – Skilled and educated engineers and technicians

- Domestic Market – Booming Chinese electronics industry driven by demand

- Government Support – Strong policy and financial incentives for PCB technology

By leveraging these strengths, PCB manufacturers in China deliver boards with excellent quality, low costs, and reliable availability. This perfectly aligns with electronics supply chain needs.

Future Outlook

China will maintain its leadership in PCB production as domestic and international demand for electronics manufacturing shows no signs of slowing. Advancing technologies like 5G communications, electric vehicles, IoT devices, and artificial intelligence ensure robust ongoing requirements for PCBs. Top Chinese PCB manufacturers continue investing heavily to push fabrication capabilities further. However, factors like rising labor costs and growing environmental regulations do pose challenges. Still, China appears positioned to extend its reign as the factory floor producing the printed circuit boards powering the global digital economy.

FQA

What are some key industries relying heavily on PCBs made in China?

Major industries fueled by Chinese PCB production include consumer electronics, smartphones, computers, communications infrastructure, automotive electronics, industrial automation, and Internet of Things.

What emerging innovations are likely to drive demand for Chinese PCB manufacturing capabilities?

Emerging electronic product innovations requiring sophisticated PCBs include electric vehicles, autonomous drones, virtual reality devices, IoT wearables, 5G infrastructure, and artificial intelligence accelerators.

How has Chinese PCB manufacturing expertise expanded over the years?

Chinese manufacturers have rapidly scaled competencies in advanced PCBs including HDI, rigid-flex, RF designs, quickturn prototyping, automotive boards, and cutting edge packaging substrates.

What are some factors that may constrain China’s PCB manufacturing growth?

Constraints facing China could include rising labor and regulatory costs, inadequate IP protections, trade barriers erected by other nations, aging demographics, and environmentally driven production caps.

How competitive is the PCB manufacturing landscape within China?

The Chinese PCB industry is intensely competitive with thousands of domestic fabricators competing mainly on cost and delivery but also increasingly on technology and capabilities.