Introduction

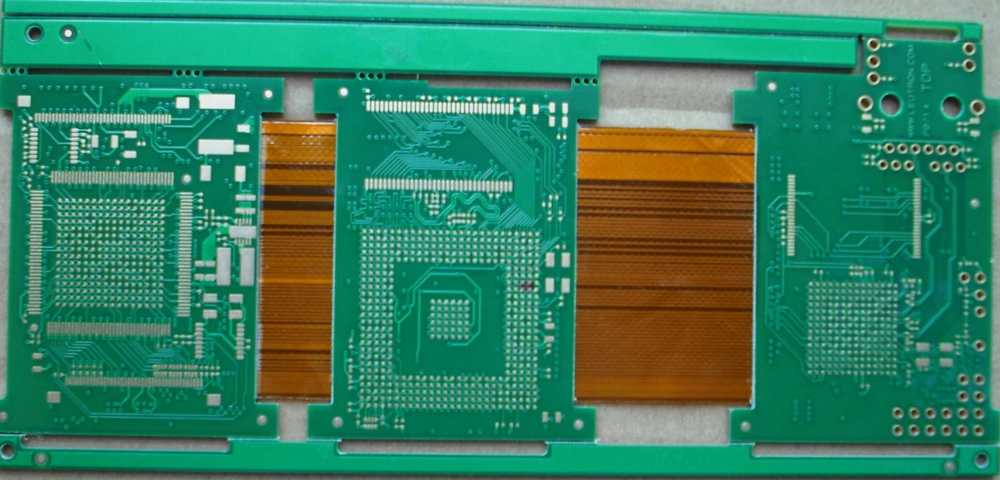

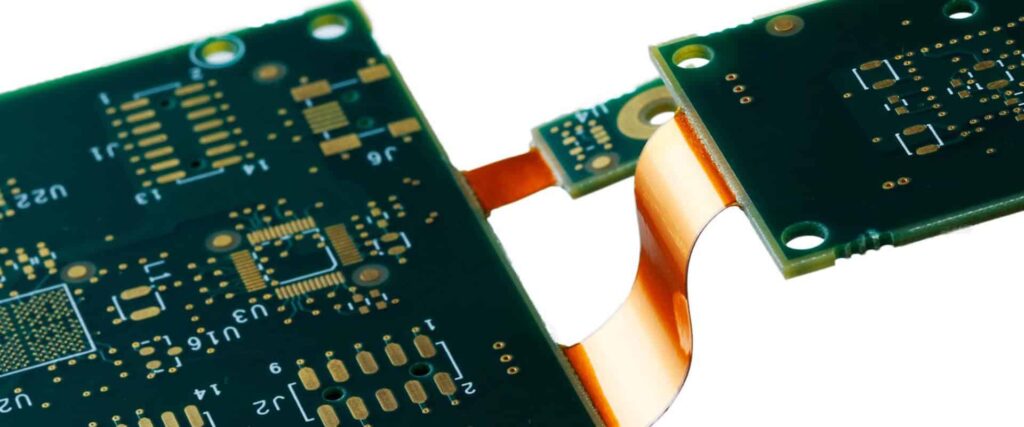

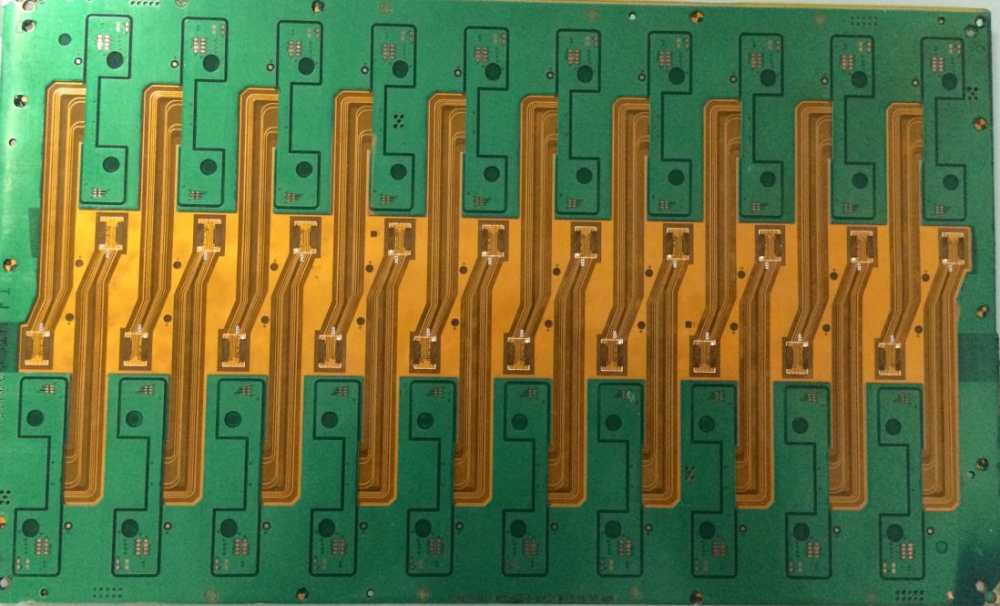

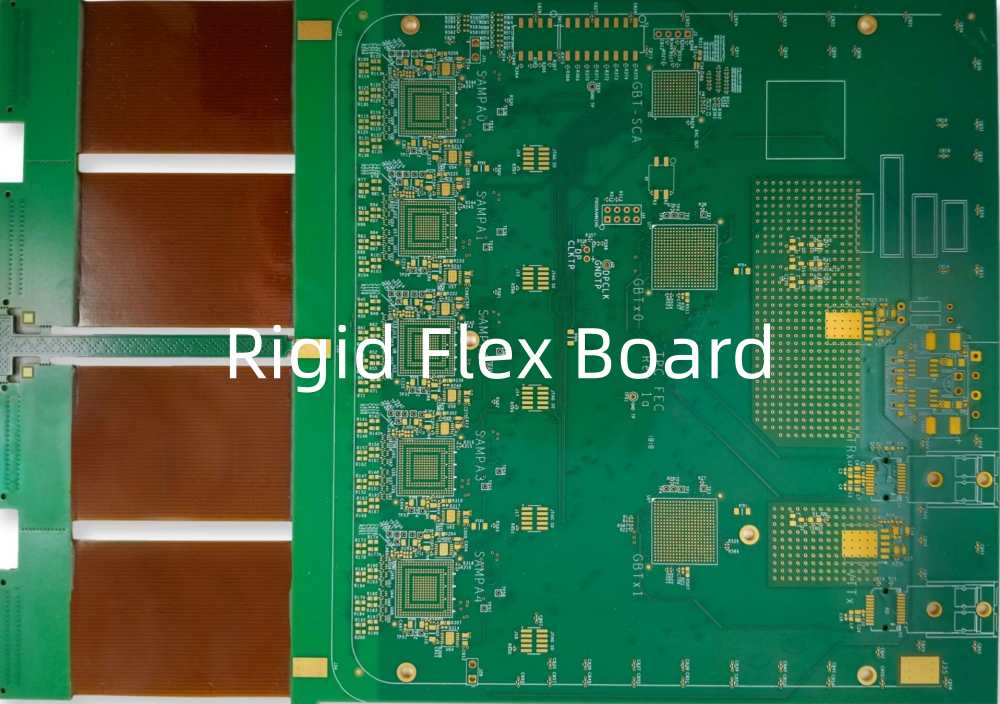

Rigid-flex PCBs integrate rigid PCB sections and flexible PCB circuits together into one interconnected assembly. They provide solutions for electronic devices and products that require high density interconnections, dynamic flexing, and packaging in 3D spaces.

With growing adoption in products from wearables, medtech, aerospace, consumer electronics, IoT devices, and more, the market for rigid-flex PCBs is rapidly expanding. This has led to an increase in manufacturers specializing in rigid-flex PCB technology and services to meet rising demand.

This article provides a ranking of the top 15 rigid flex PCB manufacturers worldwide. The rankings are based on company revenue, production capabilities, technology expertise, service offerings, and industry reputation. The list includes details on each manufacturer along with their capabilities, and highlights what sets them apart from competitors.

Understanding the landscape of leading rigid-flex PCB suppliers worldwide helps identify qualified vendors for your prototype through high-volume production needs in different global regions.

Ranking of Top 15 Rigid Flex PCB Manufacturers Worldwide

| Rank | Company | Country | Key Facts |

|---|---|---|---|

| 1 | TTM Technologies | USA | – 2019 Revenue: $2.7B+<br>- Employs >16000 staff<br>- 9 manufacturing plants globally |

| 2 | Rayming Technology | China | – Founded in 2002<br>- Employs >6000 staff<br>- Specializes in HDI, rigid-flex, RF boards |

| 3 | AT&S | Austria | – 2019 Revenue: $1.25B<br>- Publicly traded company<br>- Highly automated manufacturing |

| 4 | Compass Technology Company Limited | China | – Founded in 1998 <br>- Employs >5000 staff<br>- 8 manufacturing facilities |

| 5 | Flexium Interconnect | Taiwan | – Founded in 2000<br>- Employs >8000 staff<br>- 2019 Revenue: $1.1B |

| 6 | Zhen Ding Tech | Taiwan | – Founded in 1980<br>- 2019 Revenue: $1B<br>- ISO 13485 and AS9100 certified |

| 7 | Career Technology | Taiwan | – Founded in 1999<br>- 2019 Revenue: $872M<br>-Employs >6000 staff |

| 8 | Flexduc | Denmark | – Founded in 1969<br>- Employs >120 staff<br>- Specialized in small-medium volumes |

| 9 | SigmaTron International | USA | – Founded in 1993<br>- Employs >4500 staff<br>- 8 manufacturing plants |

| 10 | Multi-Fineline Electronix | USA | – Founded in 1998<br>- Acquired by Suzhou Dongshan Precision Manufacturing Co. in 2017 |

| 11 | Royal Circuits | USA | – Founded in 1989<br>- Employs >500 staff<br>- ITAR registered and AS9100 certified |

| 12 | Sunway Communication | China | – Founded in 2001<br>- Employs >3000 staff<br>- 2019 revenue: $400M+ |

| 13 | Chin-Poon Industrial | Taiwan | – Founded in 1988<br>- Employs >7000 staff<br>- 2019 Revenue: $800M+ |

| 14 | Lenthor Engineering | USA | – Founded in1966<br>-Employs >100 staff<br>-AS9100 and ISO 13485 certified |

| 15 | Streamline Circuits | USA | – Founded in 2002<br>- Woman-owned business<br>- ITAR registered and IPC Class 3 certified |

Overview of Top Rigid Flex PCB Manufacturers

1. TTM Technologies

TTM Technologies is one of the largest PCB manufacturers worldwide with a broad footprint spanning North America, Europe, and Asia. The company had revenues exceeding $2.7 billion in 2019.

TTM offers a comprehensive range of rigid, flex, and rigid-flex PCBs, with advanced technologies for high density interconnects, RF boards, power electronics, thermal management, and more. They have extensive expertise in producing complex rigid-flex PCBs for mission-critical defense, aerospace, medical, instrumentation, networking, and automotive applications.

2. Rayming Technology

Founded in 2002, Rayming Technology has established itself as a leading rigid-flex PCB manufacturer in China. The company employs over 6000 people across multiple factories and has a annual production capacity exceeding $500 million.

Rayming specializes in manufacturing complex and high-reliability products including high density interconnect (HDI), rigid-flex, RF/microwave, and metal-based PCBs. The company is widely recognized for its expertise in rigid-flex PCB technology.

3. AT&S

AT&S is a publicly traded European company that provides specialized high-end PCB solutions. They had over $1.25 billion in revenues in 2019.

The company has production facilities in Austria and India to manufacture HDI, flexible, rigid-flex, and high frequency PCBs. AT&S rigid-flex circuits power many applications in the automotive, medical technology, industrial, transportation, and aerospace sectors.

4. Compass Technology Company Limited

Compass Technology is a China-based PCB manufacturer founded in 1998. The company has revenues exceeding $500M with over 5000 employees.

Compass Technology runs 8 manufacturing facilities in China producing rigid, flex, rigid-flex, HDI, and metal base boards. They specialize in quick-turn prototyping as well as mass production of complex PCBs.

5. Flexium Interconnect

Flexium is headquartered in Taiwan with manufacturing operations also in China and Mexico. The company was founded in 2000 and generates over $1 billion in annual revenues.

Flexium manufactures a wide range of PCBs, with an emphasis on fine line multilayers, HDI rigid boards, flexible circuits, and rigid-flex. They serve the networking, telecom, automotive, aerospace, medical, defense, and instrumentation industries.

6. Zhen Ding Tech

Zhen Ding Tech, also based in Taiwan, provides advanced PCB and substrate manufacturing solutions globally. Founded in 1980, the company has revenues exceeding $1 billion per year.

Their products include flex and rigid-flex PCBs supporting high complexity requirements. Many divisions are ISO 13485 and AS9100 certified. Zhen Ding Tech specializes in high mix, low volume PCB production.

7. Career Technology

Career Technology is a Taiwan-based manufacturer of flexible and rigid PCBs, including rigid-flex. Established in 1999, the company employs over 6000 staff and had 2019 revenues of $872 million.

Career Technology operates an extensive global supply chain and logistics network to serve customers worldwide. They provide mass production capabilities as well as prototypes and new product introduction services.

8. Flexduc

Flexduc, located in Denmark, specializes in the manufacture of challenging flexible, rigid, and rigid-flex PCBs. Founded in 1969, the company has over 50 years of experience in high-mix, low to medium volume PCB production.

Flexduc produces ultra-high layer count boards along with flex and rigid-flex circuits for the medical, industrial, aerospace, and instrumentation sectors. They focus on highly complex technologies and quick-turn support.

9. SigmaTron International

Headquartered in Illinois, SigmaTron International provides electronic manufacturing services and PCB assemblies globally. The company was founded in 1993 and employs over 4500 staff across 8 manufacturing facilities.

SigmaTron manufactures printed circuit boards including traditional rigid, flexible, and rigid-flex boards supporting low to mid volume production. Their specialized services include design for manufacturing (DFM) and new product introduction (NPI).

10. Multi-Fineline Electronix

Multi-Fineline Electronix (MFLEX) was a California-based flexible and rigid-flex PCB manufacturer acquired by Suzhou Dongshan Precision Manufacturing Co. in 2017.

The company focuses on producing ultra-high density interconnects and miniaturized flex and rigid-flex boards for consumer electronics, medical products, military systems, automotive electronics, and aerospace applications.

11. Royal Circuits

Founded in 1989, Royal Circuits offers quick-turn printed circuit board manufacturing out of their California facility. The company employs over 500 people and is ITAR registered.

Royal Circuits fabricates a range of rigid, flexible, and rigid-flex printed circuit boards in prototype to mid-volume production. They specialize in supporting startups, small companies, and engineers with fast time-to-market.

12. Sunway Communication

Sunway Communication is a Chinese PCB manufacturer with significant capabilities in producing rigid, flex, and rigid-flex boards. Founded in 2001, the company generates over $400M in annual revenues.

Their manufacturing facilities house advanced processes and equipment to produce multilayer, HDI, flexible, and metal-based PCBs. Sunway supplies products globally to automotive, industrial, medical, defense, and other technology customers.

13. Chin-Poon Industrial

Based in Taiwan and founded in 1988, Chin-Poon Industrial manufactures automotive, industrial control, aerospace, instrumentation, and telecom PCBs. Their 2019 revenues exceeded $800 million.

The company operates factories in Taiwan along with China, Vietnam, Mexico, and India. In addition to conventional rigid boards, Chin-Poon provides flex and rigid-flex PCB technology and services.

14. Lenthor Engineering

Lenthor Engineering is specialized flexible circuit manufacturer located in Florida. Founded in 1966, the company produces a wide array of flexible circuits along with rigid-flex boards.

Their products serve the medical, military, aerospace, transportation, and instrumentation industries. Lenthor leverages their AS9100 and ISO 13485 quality certifications to produce high-reliability PCBs.

15. Streamline Circuits

Streamline Circuits, established in 2002, manufactures a diverse range of rigid and flexible PCBs out of their California facility. The company is women-owned and ITAR registered.

Streamline Circuits provides prototype through production of conventional rigid, flex, and rigid-flex boards. Their products serve the defense, aerospace, medical, industrial, and electronics industries. They are IPC Class 3 certified.

Leading Countries for Rigid Flex PCB Manufacturing

The top country locations for rigid-flex PCB manufacturing globally based on production output are:

China – As the worlds’s largest producer of PCBs overall, a significant amount of rigid-flex production is based out of China due to the country’s expansive manufacturing infrastructure. Many major players have facilities in China.

Taiwan – Taiwan has a well-established PCB industry and home to leading rigid-flex manufacturers including Flexium, Zhen Ding Tech, and Career Technologies.

USA – Despite shifts toward Asia, the USA still retains advanced PCB and flexible circuit production capabilities from both domestic and foreign companies with stateside factories.

Austria – AT&S in Austria provides the country with specialized rigid-flex manufacturing capabilities targeted at high-technology sectors.

Other Notable Countries – Germany, Japan, Mexico, Denmark, India, and Vietnam also have varying presence in the rigid flex PCB market.

Applications and End Products Using Rigid Flex PCBs

Some of the key industries and applications using rigid-flex PCB technology:

- Aerospace – Flight control systems, engine controls, navigation and guidance systems

- Military/Defense – Missile guidance, radars systems, communications, wearables

- Medical – Hearing aids, imaging equipment, prosthetics, surgical robots

- Automotive – Drive systems, charging systems, infotainment controls

- Consumer Electronics – Laptops, tablets, mobile phones, wearables

- Internet of Things – Sensors, controls, edge/gateway devices

- Instrumentation – Portable measurement equipment, test and measurement systems

- Industrial – Robotics, automation systems, human-machine interfaces

Benefits of Rigid Flex PCBs

Some key benefits that rigid-flex PCBs provide:

- Combines multiple rigid and flex PCBs into single integrated assembly

- 3D packaging and space savings

- Dynamic flexing and motion capabilities

- Eliminates interconnecting cables and connectors

- Improved reliability with fewer interconnects

- Increased product miniaturization

- Design flexibility

- Efficient high-speed signal routing

- High-density component mounting

- Reduces system assembly time

- Facilitates faster new product introduction

How to Select a Rigid Flex PCB Manufacturer

Here are some tips on evaluating and selecting a rigid-flex PCB manufacturing partner:

- Review company certifications, qualifications, and expertise in rigid-flex

- Assess technical capabilities based on your product needs

- Look for expertise in related technologies like HDI and advanced materials

- Evaluate global supply chain and logistics for your production region

- Understand their design, prototyping, and new product introduction (NPI) services

- Review quality control and assurance procedures and certifications

- Analyze testing and inspection capabilities to ensure reliability

- Examine facilities and manufacturing infrastructure

- Determine scalability for volumes from prototypes to mass production

- Review references and evaluate customer service and support

Conclusion

Rigid-flex PCB technology enables product miniaturization, increased functionality, enhanced reliability, and improved life cycle cost savings in a broad range of defense, aerospace, automotive, medical, electronics, and industrial applications.

As product complexity and electronics content continues growing across these sectors, adoption of advanced PCBs like rigid-flex will accelerate. This article provided an overview of the top rigid flex PCB manufacturers around the world who have the expertise and capabilities to deliver robust solutions from prototype to volume production.

Understanding the landscape of leading rigid-flex PCB suppliers globally helps identify qualified vendors to partner with for your next product design and manufacturing program.

Frequently Asked Questions

Q: What are some key factors to consider when selecting a rigid-flex PCB manufacturer?

A: Important selection criteria include technical capabilities, manufacturing expertise, certifications, supply chain and logistics, capacity for volume production, design and NPI services, quality processes, customer service and support levels.

Q: What types of products commonly use rigid-flex PCB technology?

A: Key applications are in aerospace, military equipment, medical devices, automotive electronics, robotics, instrumentation, wearable devices, laptops and other consumer electronics.

Q: What are the main benefits of using a rigid-flex PCB?

A: Benefits include space/weight savings, elimination of wires and connectors, improved reliability, design flexibility, high-density mounting, dynamic flexing ability, faster assembly, and miniaturization.

Q: Can rigid-flex PCBs integrate both single-sided and double-sided flex circuits?

A: Yes, rigid-flex allows integration of multiple layer rigid sections combined with single or double-sided flex circuits all into one consolidated assembly.

Q: How do you test a completed rigid-flex PCB assembly?

A: Rigid-flex PCBs can be tested using fixtures that provide support and avoid over-flexing of curves. Flying probe testing is also used given the mix of rigid and flex portions.