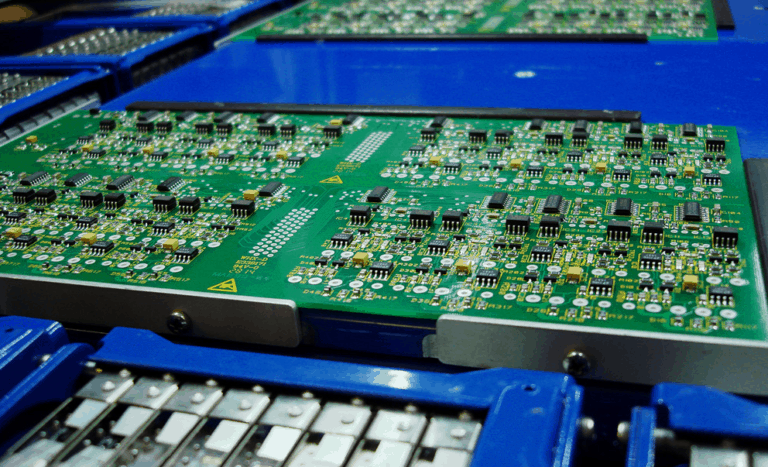

San Diego serves as a major hub for electronics innovation and high tech manufacturing. Its temperate climate, educated workforce talent, and proximity to the California Institute for Telecommunications and Information Technology and other leading universities enable a thriving environment for printed circuit board (PCB) fabrication and assembly services to support product developers.

This article profiles the top PCB manufacturing and assembly companies in San Diego county that deliver quality, reliability and leading edge technological capabilities.

Overview of PCB Industry in San Diego

San Diego emerged as a prominent location for PCB technology due to:

- Deep pool of PCB design engineering talent from UCSD and other universities

- Numerous electronics, defense, and telecommunications OEMs requiring rapid prototyping through production

- Favorable logistics for receiving raw PCB materials and distributing finished boards

As a result, investors poured over $194 million from 2016-2021 into local PCB fabrication startups to meet demand. The industry directly employs over 5,000 skilled technicians in San Diego county.

And PCB manufacturing shows no signs of slowing with electronics playing an ever expanding role across every industry. San Diego PCB shops continue investing in the latest equipment and best practices to stay ahead of customer needs.

Leading PCB Manufacturing Services in San Diego

Many renowned PCB fabricators established manufacturing centers in San Diego or got their start in the area before expanding globally. They provide sophisticated technologies from multilayer, high density interconnects to RF boards cost effectively right in the San Diego backyard of so many customers.

Here are the top local PCB manufacturing leaders:

1. Epec Engineered Technologies

Location: Vista, CA

Background: Founded in 1983, grown to over 140 employees

Capabilities:

- Multilayer PCBs – up to 36 layers

- 5-day prototyping turnaround

- Blind and buried vias

- 0.5 mm line/space

- Flex and rigid-flex boards

- Defense and medical certifications

Website: epectec.com

2. AP Circuits

Location: San Diego, CA

Background: Operating since 1975, over 45 years of PCB experience

Capabilities:

- Quick turn prototypes – 24-48 hrs

- Multilayer boards – up to 16 layers

- 0.003” line/space traces

- Lead-free RoHS compliant

- ITAR registered

Website: apcircuits.com

3. Spectra Circuits

Location: San Marcos, CA

Background: Founded in 1986, over 150 employees

Capabilities:

- Multilayer PCBs – up to 30 layers

- Blind/buried vias, microvias

- 0.005” line/space

- Cross-section up to 60 layers

- Defense/medical/telecom certifications

Website: spectracir.com

4. Freedom CAD Services

Location: San Diego, CA

Background: Established in 2002, 18 years operation

Capabilities:

- Prototype PCBs in 5 days

- HDI technology

- Laser drilling to 0.005”

- 0.8 mm vias

- Flex, rigid-flex boards

- 0.003” lines/spaces

Website: freedomcad.com

These well established manufacturers offer the technology breadth, quality consistency, capacity and responsiveness sought after by engineers for low-high volume applications.

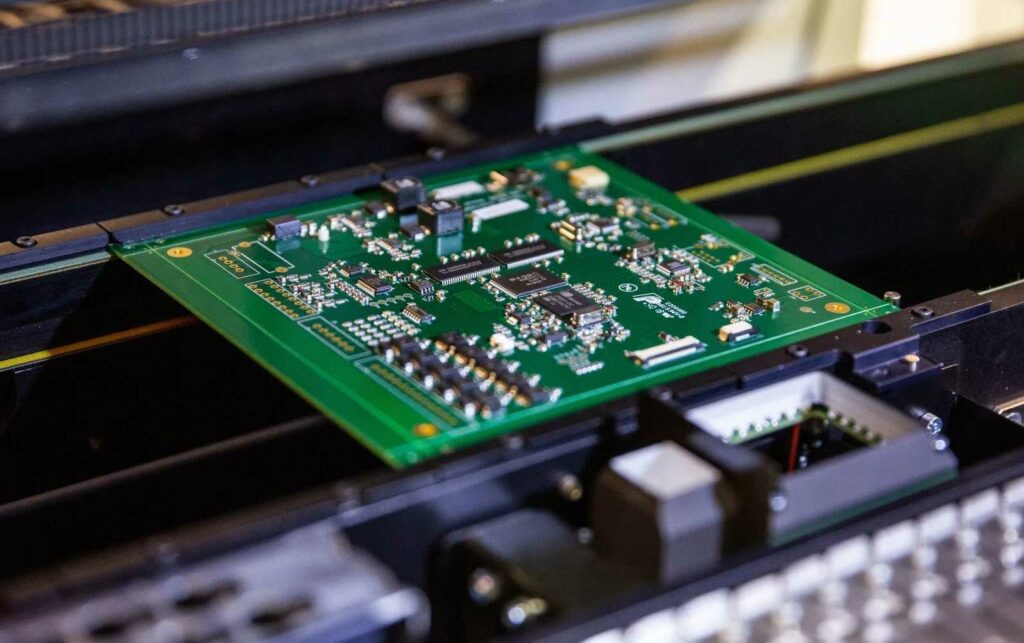

Top PCB Assembly Companies in San Diego

In addition to PCB fabrication, San Diego provides access to expert assembly of electronic components onto printed boards – including automated optical inspection (AOI), test, product packaging and fulfillment.

Local PCB assembly service bureaus add tremendous value enhancing electronics with rapid ramps to mass production. They save startups and smaller firms from costly capital investment in in-house SMT lines until reaching necessary economies of scale.

Below are leading electronics manufacturing services (EMS) and smaller specialty shops performing PCB assembly in the greater San Diego region:

1. A steel Manufacturing

Location: San Diego, CA

Background: Established in 1998

Capabilities:

- SMT assembly down to 0201 components

- Automated optical inspection

- Functional/environmental stress testing

- Box build, product packaging

- Low to high volume

Website: asteelmfg.com

2. Ohm Temp Services

Location: Carlsbad, CA

Background: Founded in 1992

Capabilities:

- High-mix, low-mid volume assembly

- Lead-free processing

- Selective soldering

- Conformal coating

- Design for manufacturing guidance

Website: ohmtempservices.com

3. Screaming Circuits

Location: Barrio Logan, San Diego, CA

Background: Established in 2002 by former Qualcomm engineers

Capabilities:

- Quick-turn prototyping

- Low volume, high mix

- Minimal order quantities

- ITAR and defense work

Website: screamingcircuits.com

These nimble San Diego based assembly companies cater towards optimizing complex boards for regional startups and small firms through scalable mid-volume production. Their strategic location and responsiveness makes them easy business partners for getting prototypes built fast and ramping smoothly to initial market release.

PCB Technology Comparison Matrix in San Diego Region

| Parameter | Basic Spec | Enhanced Spec | Advanced Spec |

|---|---|---|---|

| Line Width / Space | 0.003” | 0.0025” | <0.001″ |

| Layer Count | 6 layers | 16 layers | >20 layers |

| Via Structure | Through hole | Blind/buried | Microvias |

| Lead Time | 7-10 days | 5 days | 24-48 hrs |

| Assembly Partner | Manual | Automated | High density |

| Test Services | Basic | Intermediate | Complex RF |

| Volume Range | 1-1K units | 1K-10K+ | 10K+/yr+ |

| Cost | Lower | Moderate | Higher |

This table captures broad technology segments from entry level to advanced supported within San Diego – enabling innovators to find the right PCB partner matching respective budget, schedule and capability needs through all phases of market introduction.

Selecting the Ideal PCB Company in San Diego

Choosing the best PCB fabrication and assembly partner depends greatly on individual product requirements and corporate resources.

Key Decision Drivers

Technical Factors

- Layer count, density needs

- Material types – FR4, Rogers, ceramic

- Line width/space, via dimensions

- Pad, hole plating specs

- Certification needs – ISO, ITAR, IPC Class 3

Production Considerations

- Prototyping to low-high volume ramp plan

- Standard vs. quick turnaround need

- Geographic location

- Quality process maturity

Service Capabilities

- Design for manufacturing (DFM) reviews

- Supply chain coordination

- Testing services

- Programming, client IP protection

Financial Elements

- Budget

- Payment terms

- Production scalability pricing

Firms prioritize selection criteria based on specific objectives for the electronics product roadmap and aligned supplier synergies. Sourcing multiple quotes from leading candidates provides further clarity confirming the ideal San Diego PCB plant.

Future Outlook for San Diego’s PCB Industry

San Diego’s temperate climate, coastal location, engineering school pipeline, and growing tech hub make it a sought after geography for PCB companies. Commercial and defense electronics manufacturers increasingly near-shore production to regional fabricators enabling greater quality control and supply chain resilience.

And local PCB manufacturers continue investing in the latest equipment and best talent to support customers. Recent growth areas include:

- High density interconnect (HDI) flex boards

- Higher layer count multilayer boards

- Laser direct imaging (LDI)

Exciting startups spawn each year from San Diego’s universities focused on pushing PCB technology forward. They join a long list of trusted incumbent PCB shops equally prepared to build tomorrow’s electronics innovations across defense, telecom infrastructure, autonomous vehicles, IoT, and more.

Frequently Asked Questions

Q: How long do PCB prototype orders take in San Diego?

Most shops deliver initial prototypes within 5-7 business days. Some specialize in 24-48 hour expedited fabrication to help meet urgent deadlines.

Q: Does San Diego offer PCB assembly services?

Yes, San Diego provides extensive electronics manufacturing services for low-high mix