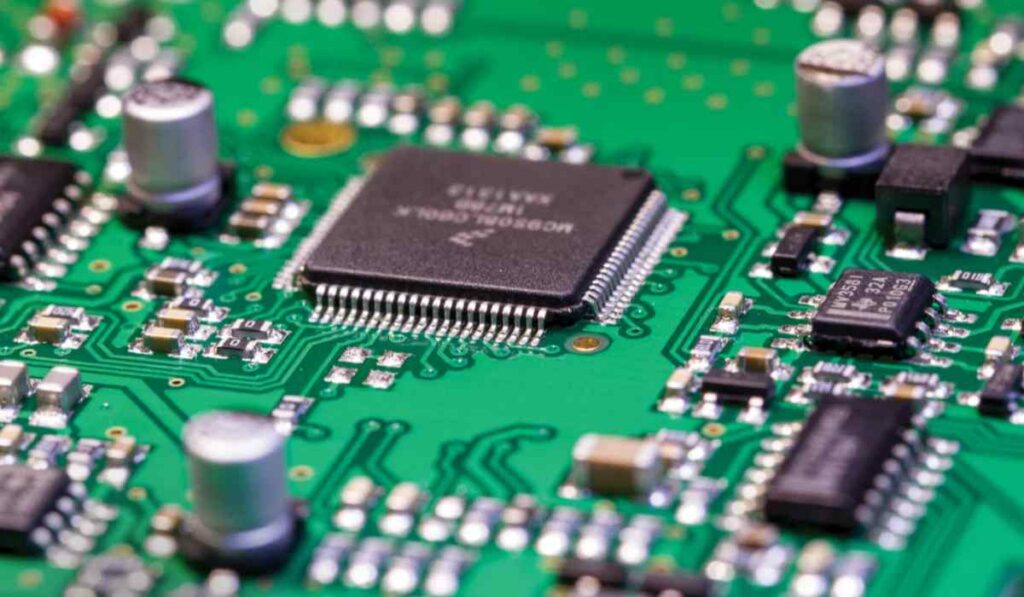

Electronics manufacturing is the process of designing, fabricating, assembling, and testing electronic components, devices, and systems ranging from microchips to smartphones to aircraft instrumentation. The electronics manufacturing industry has revolutionized products and lifestyles by enabling sophisticated capabilities and connectivity.

Electronics manufacturing is a complex, highly engineered discipline that combines materials science, electrical engineering, mechanical engineering, computer science, automation, and manufacturing expertise. Here is an overview of the key activities encompassed in modern electronics manufacturing:

Research and Development

Extensive research and development is conducted to create new electronic devices and translate them into mass-producible products. This involves:

- Developing new semiconductor processes and materials

- Designing and prototyping new circuits and architectures

- Creating intellectual property like proprietary algorithms

- Simulating, modeling, and testing performance

- Evaluating manufacturability and costs

- Patenting inventions

Multibillion-dollar R&D investments by leading electronics companies drive rapid advancement.

Process Engineering

Specialized manufacturing processes turn raw materials into complex integrated circuits, components, printed circuit boards (PCBs), electromechanical assemblies, and modules. Key processes include:

- Semiconductor fabrication including wafer growth, photolithography, doping, thin films deposition, etching, cleaning, inspection

- Component fabrication processes like molding, stamping, die casting, surface mount technology (SMT) production

- PCB fabrication involving laminating, drilling, imaging, plating, etching, coating

- Precision machining, tooling, injection molding, and other manufacturing processes

- Metrology techniques like optical inspection, x-ray imaging, electrical testing, thermal profiling

- Advanced automation including robotics assembly, conveyors, and logistics

Supply Chain Management

The worldwide electronics supply chain enables sourcing of components, raw materials, chemicals, gases, consumables, equipment, and other manufacturing inputs spanning global networks of suppliers, distributors, and partners. Supply chain logistics, distribution, and warehouse management deliver parts where needed during production.

Compliance and Certification

Regulations, standards, and customer requirements guide the certification of quality management systems, environmental management, safety, ethics, security, material content, and other priorities. Compliance helps manage business continuity risks.

Assembly and Integration

Full assembly transforms components into functioning modules, boards, systems, and finished products. This involves:

- Surface mount technology (SMT) automated assembly of components onto PCBs

- Through-hole component insertion and soldering

- Interconnecting boards, wiring harnesses, electromechanical modules

- Integrating subassemblies like displays, chassis, enclosures, and covers into final products

- Programming installed firmware and boot software

- Testing subassemblies and end products

- Repairing, reworking, and troubleshooting

Quality Assurance

Rigorous quality assurance steps validate proper function, performance, reliability, and aesthetics at all points in manufacturing including incoming, in-process, and final testing:

- Inspecting, measuring, and testing against specifications

- Detecting process deviations and defects

- Burn-in stress cycling to validate reliability

- Maintaining quality documentation and traceability

- Issuing corrective actions to resolve issues

- Improving processes and inspection methods

Quality is crucial for product integrity.

Sustainability and Green Initiatives

Electronics manufacturing impacts the environment through energy and water use, emissions, and material waste. Companies implement sustainability initiatives like:

- Energy conservation and renewable energy

- Water reclamation and responsible water sourcing

- Waste reduction and recycling programs

- Reducing use of hazardous materials

- Supply chain accountability and conflict mineral avoidance

- Product life cycle assessments

- Reusable packaging

Customer Support and Service

Providing technical customer service and product support is vital for sustaining long term relationships. This includes:

- Issue tracking and technical troubleshooting

- Customer feedback analysis

- Warranty and repair services

- Spare parts inventory and logistics

- Field engineering and technician training

- Documentation and knowledge base access

- Return material authorizations (RMAs)

Driving Electronics Innovations

Electronics manufacturing combines multi-disciplinary engineering with large-scale production and supply chain prowess to manufacture the products empowering digital transformation across every industry. Continued research, investment, and improvement across these interconnected activities will enable ongoing electronics advances that shape business and society.

Key Electronics Manufacturing Segments

Major segments within the electronics manufacturing industry include:

Semiconductor Fabrication

- Silicon wafer production and microchip fabrication in foundries

- Optoelectronics including LEDs and lasers

- MEMS sensors and actuators

- Advanced IC packaging

Passive Components

- Resistors, capacitors, inductors, transformers

- Antennas, filters, connectors and electromechanical parts

Electronic Contract Manufacturing

- Printed circuit board assembly (PCBA)

- Full product assembly and test

Consumer Electronics

- Smartphones, computers, tablets

- Televisions, home audio, game consoles

- Wearables, smart home devices

Automotive Electronics

- Engine control units, infotainment

- ADAS sensors, cameras, radar

- Lighting, electric powertrain components

Industrial and Medical Electronics

- Programmable logic controllers (PLCs)

- Process transmitters and instrumentation

- Medical imaging systems

Geographic Manufacturing Hubs

Major electronics manufacturing clusters exist in:

- East and Southeast Asia (China, South Korea, Japan, Taiwan)

- United States (California, Texas, Illinois)

- Europe (Germany, France, UK, Hungary, Turkey)

- Mexico and South America

- India

Major Companies

Leading global electronics manufacturers include:

- Contract manufacturers – Foxconn, Flex, Jabil

- Brands – Apple, Samsung, Dell, HP, LG

- Semiconductor – Intel, TSMC, Qualcomm, Broadcom

- PCB fabricators – Compeq, Unimicron, Tripod, Nan Ya PCB

Hundreds of companies drive innovation across the vibrant electronics industry ecosystem worldwide.

The Future of Electronics Manufacturing

Emerging trends impacting electronics manufacturing include:

- Continued automation and adoption of Industry 4.0

- Accelerating pace of technological change

- Growing importance of software and data analytics

- Supply chain optimization and resiliency

- Expansion of green/sustainable manufacturing

- Demand for customized and personalized devices

- Development of smart factories and cities

Electronics manufacturing will continue growing in strategically important as an enabler of technology innovation worldwide.

FQA

What are the major steps involved in manufacturing integrated circuits and silicon chips?

Chip fabrication involves crystal growth, wafer preparation, photolithography, doping, thin film deposition, etching, dicing, assembly, bonding, encapsulation, marking, and testing processes performed in ultra clean environments.

What are some key differences between consumer electronics and industrial electronics manufacturing?

Consumer electronics focus on user experience, aesthetics, branding, rapid innovation, and optimizing cost and time to market. Industrial electronics demand extreme reliability, environmental resilience, long product lifecycles, and closed loop quality control.

What role do electronics manufacturing services (EMS) provide?

EMS specialize in offering electronics companies outsourced manufacturing, assembly, testing, supply chain management, and other services to build products designed by the hiring firm.

How has automation transformed modern electronics manufacturing?

Automation with robotics, conveyors, sensors, and software analytics now assembles PCBs, performs inspection, enables rapid material logistics, and provides intelligence to streamline and adapt processes faster than human operators alone.

What are some key enablers allowing more customized and flexible electronics manufacturing?

Enablers include reconfigurable robotics, additive manufacturing, cloud-based manufacturing integration, virtual modeling, flexible electronics materials, and data-driven production optimization.