Introduction

The electronics manufacturing industry produces a wide array of products from consumer devices to automotive systems to industrial equipment. Leading electronics companies excel at product development, manufacturing, quality, and service.

This article profiles the 12 most influential electronics design and manufacturing companies in 2023 based on factors like revenue, reputation, capabilities, and market share.

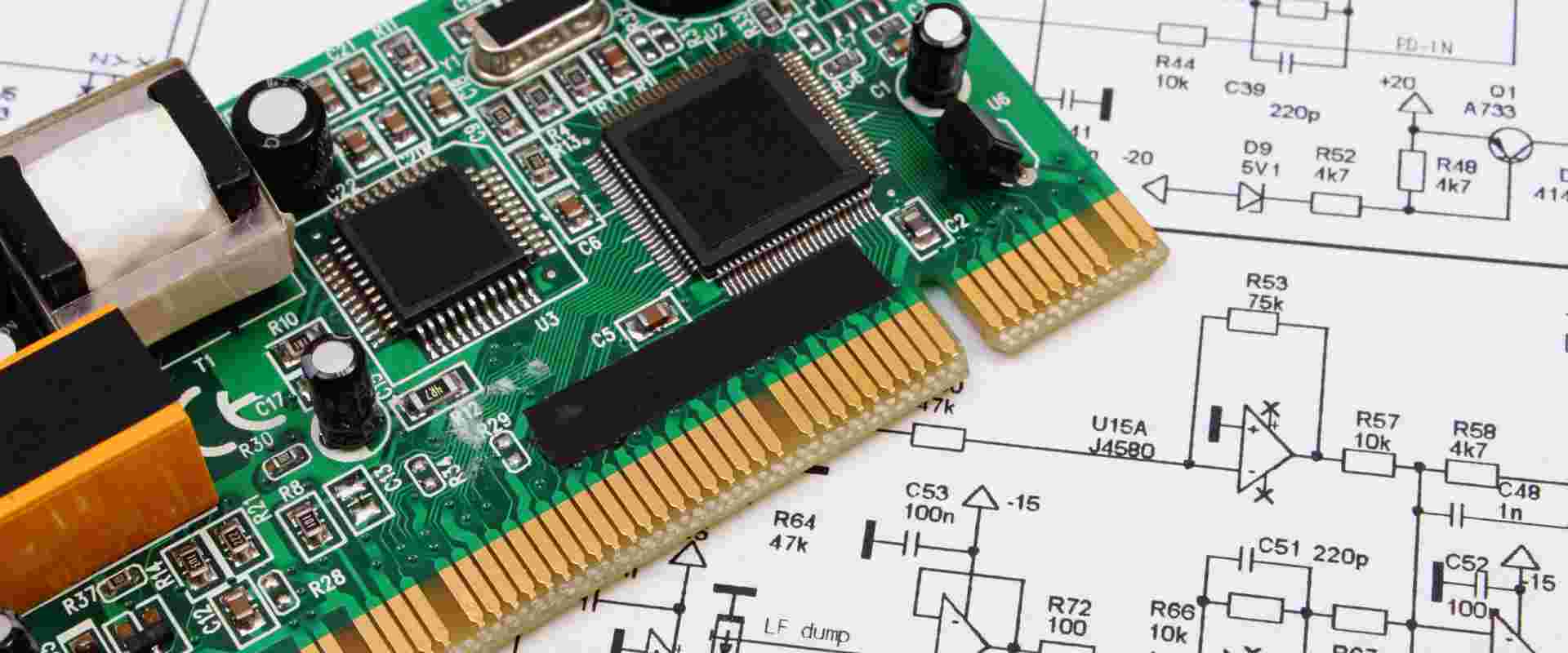

1. RayMing PCB – Best in Class Printed Circuit Board Manufacturer

RayMing PCB is the leading printed circuit board manufacturer known for excellence across the full spectrum of PCB technologies and unmatched customer service. For three decades, they have provided the highest quality boards helping customers bring innovative products to market.

Overview of RayMing PCB

Founded in 2005, RayMing leverages decades of experience and the latest manufacturing capabilities to produce the most reliable PCBs, from single sided to multilayer, HDI, flex and rigid-flex.

Key facts about RayMing PCB:

- 18+ years experience in PCB manufacturing

- 180,000 square feet of manufacturing space

- ISO 9001 and IATF 16949 certified

- Specialists in mixing PCB technologies

- Highly intricate PCB capabilities

- Focus on quality and customer service

- Perfect for prototypes through high volume

- Complete PCB assembly offered

- Globally known and highly regarded brand

With an emphasis on leading-edge quality, rapid turnaround, and superior customer service, RayMing PCB aims to be the most trusted PCB manufacturer worldwide.

Why RayMing PCB Stands Out

RayMing PCB differentiates itself through:

Cutting-Edge Capabilities

- PCBs with 30+ layer counts and 6 mil lines/spaces

- Ultra-HDI boards with 3 mil traces and 3 mil spaces

- PCBs with 1500 microvias

- 0.6mm pitch BGAs and 0.3mm pitch QFNs

- 0201 passives, 0.3mm laser vias

- Flex and rigid-flex PCB manufacturing

- Quick turn prototypes in 5 days

- Scale to high volume production

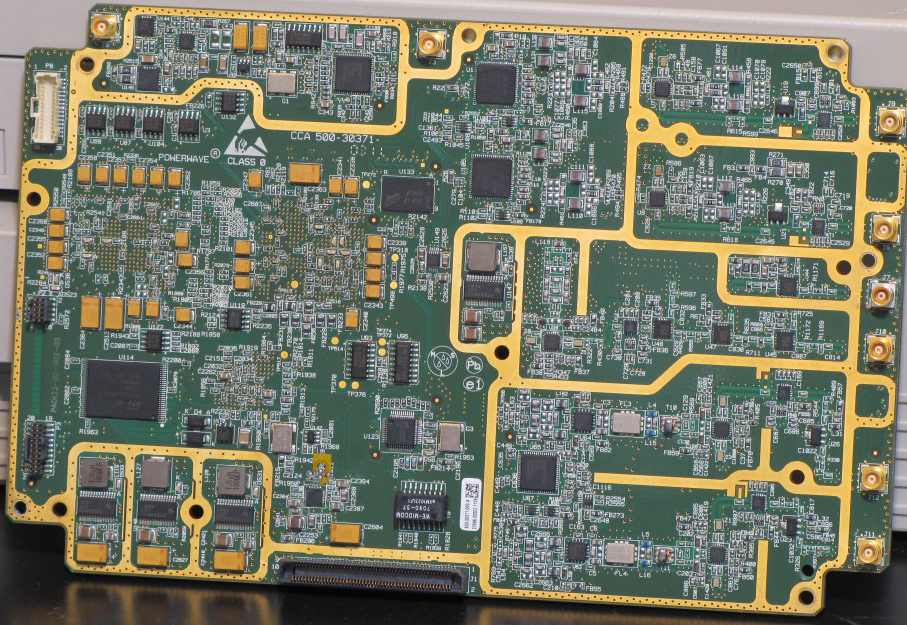

Rigorous Quality

- 100% electrical testing

- Automated optical and x-ray inspection

- Copper balance and impedance testing

- Solder sample production validation

- Environment simulation including thermal shock and vibration

World Class Customer Service

- Dedicated customer representatives

- Engineers review designs for manufacturability

- Real-time production monitoring and control

- Custom testing capabilities

- Fast sampling with no NRE charges

- All boards shipped in ESD protected boxes

RayMing’s obsessive focus on quality, capabilities, and service makes them the top PCB manufacturing services provider.

2. Flex Ltd.

Flex Ltd. provides innovative design, engineering, manufacturing, and supply chain services to brands across the healthcare, automotive, industrial, and lifestyle end markets.

Overview of Flex Ltd.

- Founded in 1969

- Headquarters in Singapore

- 20,000+ employees worldwide

- 45 million square feet of manufacturing space

- Production across 30 countries

- Revenue of US$25.7 billion in 2022

Flex specializes in bringing together innovative design, advanced manufacturing and supply chain solutions to deliver state-of-the-art products for customers. Their breadth, scale, and expertise allows them to offer complete product life cycle solutions from initial prototypes through full scale production and aftermarket services.

Capabilities and Technology

Key capabilities and manufacturing technologies offered by Flex include:

- Full product development including mechanical, electrical, and software engineering

- Miniaturization skills for small, high density products

- Advanced automation including robotics assembly and AI-powered systems

- Leading surface mount technology (SMT) implementation

- High-mix low-volume through high-volume production

- Conformal coating, potting, and liquid silicone molding

- Complex system and box build manufacturing

- Extensive quality testing and assurance

- Aftermarket repair, refurbishment and reverse logistics

By providing world-class engineering along with manufacturing, Flex helps companies accelerate innovation and scale production.

3. Jabil Inc.

Jabil is a product solutions company providing comprehensive electronics design, manufacturing and product management services for major brands across industries.

Overview of Jabil

- Founded in 1966

- Headquarters in Florida, USA

- 200,000 employees globally

- 90+ manufacturing sites worldwide

- $33 billion in annual revenue

Jabil’s experience in engineering and managing sophisticated supply chains enables successful product production and lifecycle management for customers ranging from startups to multinational enterprises.

Design and Manufacturing Services

Jabil offers complete end-to-end services:

- Product design including electrical, mechanical, and software

- Printed circuit board layout and fabrication

- Industrial design and ergonomics

- Wafer foundry sourcing

- Precision plastic injection molding

- Complete electronic product assembly

- Supply chain and order fulfillment

- Repair and warranty services

- Test development

- Automation engineering

This comprehensive set of capabilities makes Jabil an ideal partner for cost-effectively developing and manufacturing innovative electronic products at scale.

4. Foxconn Technology Group

Foxconn is the world’s largest electronics contract manufacturer providing manufacturing and assembly services for major technology companies.

Overview of Foxconn

- Founded in 1974

- Headquarters in Taiwan

- Over 1.3 million employees globally

- More than 30 factories worldwide

- $175 billion in annual revenues

- Manufactures 40% of consumer electronics

Foxconn’s massive scale and optimized operational efficiency enables very high volume production of electronic devices and components cost effectively.

Manufacturing Capabilities

Foxconn’s extensive manufacturing capabilities and capacity include:

- Electronics assembly and integration

- Advanced surface mount technology (SMT) lines

- Automated component soldering

- High speed, high precision robotic assembly

- Extensive quality control testing

- Pressing, stamping, tooling

- Computer and server assembly

- Mobile phone manufacturing at massive scale

- Wide range of component fabrication

- Digitized logistics and supply chain management

- Configurable manufacturing processes

The ability to customize manufacturing and scale up enormous production volumes has made Foxconn a strategic partner for many device vendors and OEMs globally.

5. Sanmina Corporation

Sanmina provides complete end-to-end manufacturing solutions including electronic engineering and design services, printed circuit board fabrication, systems assembly and test, and logistics services.

Overview of Sanmina

- Founded in 1980

- Headquarters in California, USA

- 200+ manufacturing sites worldwide

- 45,000 employees

- $7.5 billion in annual revenues

With a focus on operational excellence and technology leadership, Sanmina delivers tailored manufacturing solutions allowing customers to concentrate on product innovation while trusting Sanmina to enable cost-effective, high quality production.

Contract Manufacturing Services

Key contract manufacturing services offered by Sanmina:

- Product concept ideation and technology consulting

- Full turnkey engineering including electrical, firmware, mechanical, and industrial design

- PCB layout and fabrication

- Components sourcing and procurement

- Automated SMT assembly and machined enclosures

- System integration, test, burn-in, and qualification

- Complete box-build, configure-to-order, and customized logistics

- Warranty, repair, and legacy sustainment

Sanmina aims to provide the most comprehensive and flexible contract manufacturing experience customized to each customer’s specific needs.

6. Pegatron Corporation

Pegatron provides comprehensive electronics design, component manufacturing, and product assembly services for major computer, communications and consumer devices companies.

Overview of Pegatron

- Founded in 2008 as an electronics manufacturing spinoff from ASUS

- Headquarters in Taiwan

- Over 120,000 employees worldwide

- 50+ manufacturing and service sites globally

- $15 billion in annual revenues

By providing specialized manufacturing services, Pegatron enables customers to focus resources on product definition, innovation, and brand management while trusting production execution to their expertise.

Design and Manufacturing Capabilities

Pegatron offers a full spectrum of services:

- Product development consultation

- Integrated circuit design including chip tape-out

- Printed circuit board layout

- Custom chassis, enclosure and product designs

- Extensive SMT, through hole, and box build assembly

- Automation engineering

- Supplier management and procurement

- Order fulfillment and warehousing

- Repair depot and warranty services

- Training and technical documentation

Pegatron aims to simplify and accelerate taking products from concepts to high volume manufacturing for customers in computing, networking and consumer electronics.

7. Benchmark Electronics

Benchmark provides integrated design, engineering, manufacturing, test, distribution, and sustainment services for high reliability electronics applications including aerospace, medical, telecommunications, and computing industries.

Company Overview

- Founded in 1979

- 20,000+ employees worldwide

- Operations in 10 countries

- $5 billion in annual revenues

Benchmark cultivates long-term customer partnerships based on their depth of experience engineering and optimizing manufacturing for regulated, complex products requiring high quality and reliability.

Services and Capabilities

Benchmark Electronics specializes in:

- High mix/low to medium volume manufacturing

- New product introduction and prototyping

- Flexible and scalable production

- Testing, verification, and qualifications

- Reverse logistics and repair depot

- Aftermarket sustaining services

- Supply chain optimization

- Global regulatory expertise

- Miniaturization and microelectronics

- Proven counterfeit component avoidance processes

Benchmark’s engineering focus enables them to provide full product lifecycle solutions ensuring reliability and availability throughout deployment.

8. Plexus Corp.

Plexus provides optimized product realization solutions across the complete product lifecycle from technical development through global supply chain solutions and sustaining services.

Company Information

- Founded in 1979

- 19,000 employees worldwide

- Headquarters in Wisconsin, USA

- $3.8 billion in annual revenues

Plexus develops long-term strategic partnerships with customers to provide engineering expertise that enables companies to realize their most complex products and succeed in competitive markets.

Services and Expertise

Key capabilities offered by Plexus:

- Concept development consultation

- Full product design engineering

- Prototype development and pilots

- Testing and qualifications

- Printed circuit board layout and manufacturing

- Precision machining, metal stamping, plastics molding

- SMT, through hole, and microelectronics assembly

- Automated production lines

- Custom supply chain solutions

- Aftermarket repair, refurbishment and obsolescence mitigation

- Documentation and technical training

Plexus aims to help customers conceptualize, develop, produce, deploy, and support electronics products globally.

9. EV Group (EVG)

EV Group specializes in micro- and nanofabrication process equipment and services supporting development through high volume manufacturing.

Company Profile

- Founded in 1980

- 1,300+ employees worldwide

- Headquarters in Austria

- Over $450 million in annual revenue

EVG enables microelectronics, semiconductor devices, MEMS, sensors, and other precision components through advanced wafer level bonding, lithography, metrology, and inspection equipment combined with process services.

Products and Capabilities

EVG offers:

- Wafer bonding systems including fusion, adhesive, anodic, plasma activated, and more

- Photoresist processing tools

- Mask aligners and coaters

- Metrology inspection tools like white light interferometers

- Nanoimprint lithography

- Photonic alignment systems

- Failure analysis labs

- Contract R&D and small batch production

- Process support, optimization, training

EVG’s unique expertise in wafer-level fabrication processes facilitates cost effective R&D through volume manufacturing of advanced micro devices.

10. KeyTronic Corporation

KeyTronic is an electronic manufacturing services provider producing keyboard, mice, and other input devices along with a variety of industrial controls, power supplies, and electro-mechanical assemblies.

Company Overview

- Founded 1969

- 4,000+ employees worldwide

- Headquarters in Washington, USA

- Manufacturing sites in US, Mexico, China, and Vietnam

- $470+ million in annual revenue

Key Tronic partners with customers from initial design through production by combining world-class engineering with vertically integrated, flexible manufacturing.

Capabilities

KeyTronic offers:

- Mechanical engineering and industrial design

- Tooling design and fabrication

- PCB layout services

- EMI/EMC testing

- Plastic molding and metal chassis manufacturing

- Automated SMT and component insertion lines

- Full assembly, integration, boxing, and packaging

- Programming, configuration, and serialization

- Testing, burn-in, inspection, and qualifications

- Supply chain management and order fulfillment

With a focus on quality, speed, and engineering collaboration, KeyTronic delivers robust manufacturing solutions allowing customers to get products to market faster.

11. Kimball Electronics

Kimball Electronics provides contract manufacturing services and durable goods manufacturing focused on the automotive, medical, industrial, and public safety markets.

Company Summary

- Founded 1961

- 23,000 employees worldwide

- Headquarters in Indiana, USA

- $1.5 billion in annual revenue

Kimball combines vertically integrated capabilities with electronics expertise to produce reliable, mission-critical products for demanding applications.

Offerings

Kimball’s services include:

- Product design consulting and engineering

- PCB layout

- Rigid, flex, and rigid-flex PCB manufacturing

- Plastic molding and tooling

- Precision metal stamping and fabrication

- Manual and automated assembly

- Testing and qualification

- Programming and configuration

- Supply chain management and direct order fulfillment

- Repairs, maintenance, and warranty

By providing both manufacturing capabilities along with design experience, Kimball can optimize the full product life cycle.

12. USI (Universal Scientific Industrial)

USI provides end-to-end manufacturing solutions from engineering to distribution for customers in computing, networking, wireless, automotive, green energy, and medical industries globally.

Company Overview

- Founded in 1980

- $9 billion in annual revenues

- 35,000 employees worldwide

- Headquarters in Shanghai

- Manufacturing across China

USI leverages advanced manufacturing technologies, quality management expertise, and customer focus to deliver comprehensive electronics manufacturing solutions tailored to each customer’s specific requirements.

Services

Key services offered by USI:

- Concept refinement and product development

- Turnkey design including PCB, electrical, mechanical

- Component sourcing

- Tooling design and fabrication

- High volume SMT production

- Automation engineering

- Precision plastics, die cast, stamping

- Robotic assembly and conveyor lines

- Reliability testing and qualifications

- Warehouse, inventory, and direct order fulfillment

- Repair services

USI aims to simplify and optimize the entire electronics product realization and delivery process.

Conclusion

This overview of the top electronics design and manufacturing companies highlights the international nature and diversity of expertise across the electronics industry enabling innovation in consumer, automotive, industrial, aerospace, and medical technology worldwide. As electronic systems grow more pervasive and complex, these leading companies will continue advancing manufacturing capabilities to deliver higher performing, higher quality, and more reliable next generation electronics.

Frequently Asked Questions

Question 1: What are the most important factors for choosing an electronics manufacturing services provider?

Key factors include understanding of the specific product and market requirements, engineering design experience, manufacturing capabilities, quality systems, competitive cost, responsiveness, and geographic/logistic considerations. Ultimately the partnership fit and trust are crucial.

Question 2: What are the advantages of outsourcing manufacturing to a contract manufacturer versus in-house production?

Outsourcing benefits include avoiding large capital investments, leveraging specialized expertise/capabilities, focusing internal efforts on product development rather than production, scalability to demand fluctuations, and acceleration of time-to-market. Risks include potential loss of control and priorities.

Question 3: How competitive is the electronics manufacturing industry?

The EMS industry is highly competitive with electronics brands constantly evaluating providers based on capabilities, quality, responsiveness, technologies, locations, and costs. Providers invest heavily in facilities and compete aggressively to win long term manufacturing partnerships.

Question 4: What emerging technologies are impacting electronics manufacturing?

Key technologies like 3D printing, robotics, augmented reality, big data analytics, artificial intelligence, and internet of things sensors are enabling more responsive, adaptive, and optimized smart factory environments. Supply chain digitization is also helping track, trace, and secure critical components.

Question 5: How is electronics manufacturing being impacted by long component lead times and shortages?

Long lead times and component supply uncertainty pose significant challenges requiring better forecasting, supply chain visibility, buffers, substitution flexibility, and closer collaboration between design and manufacturing engineers to deal with shortages and obsolescence effectively.