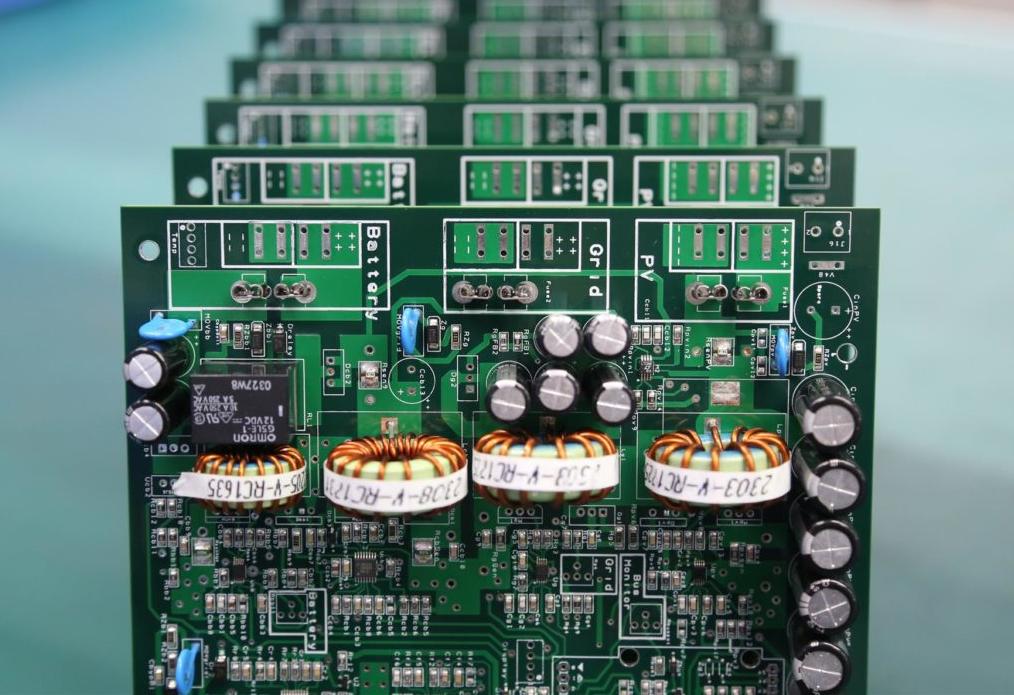

Printed circuit boards (PCB) form the foundation of electronics products serving industries from consumer appliances to aerospace systems. As products continue getting more complex and feature rich, PCB prototypes enable validation before high volume production. Selecting an appropriate PCB manufacturer capable of catering to prototyping needs can determine project success. This article compiles the top 10 global PCB prototype specialists as of 2024 suited for an array of application requirements.

Rapid prototyping combined with fabrication flexibility, strong engineering support and quality standards differentiation these highlighted PCB manufacturers. Geographic proximity, suitable factory scale, tooling and material versatility were also considered in assessments below. ested in assessments below.

1. Advanced Circuits

Location – Colorado, United States

Background – Founded in 1989, Advanced Circuits grew into the largest North American PCB manufacturer led by continual investments in latest fabrication equipment.

Offerings – Their 4 U.S. plants provide seamless prototyping scale support from simple double sided boards up to complex multilayer HDI boards within 2 to 4 days.

Strengths

- Strong IT infrastructure accepts orders 24×7 enabling rapid turnarounds

- High mix low-medium volume services support iterations

- UL certification assures reliability

Limitations – Mostly U.S. centered customer base given onshore facilities. But exports do occur.

With density capabilities rivaling offshore production coupled with fast domestic turnarounds and engineering oriented culture, Advanced Circuits dominates North American prototyping needs.

2. RAYMING PCB

Location – China

Background – Founded in 2005, RAYMING expanded to over 5000 employees providing one stop PCB and assembly solutions.

Offerings – 10 domestic factories deliver 24 hours rapid prototyping manufacture for 2 to 32 layer boards in small batches.

Strengths

- Competitive pricing with global delivery

- Accepts wide variety of file formats

- Quality benchmarking to IPC standards

Limitations – Communication barriers with English second language teams. But improving.

RAYMING established itself as a value leader catering well to North American prototyping needs leveraging China supply chain efficiencies.

3. MacroFab

Location – Texas, United States

Background – Formed in 2013, MacroFab brings cloud connected order automation to circuit board production.

Offerings – The digital platform managing fabrication accepts nearly instant quotes with batch production in under 5 days.

Strengths

- Software integration and API ordering streamlines procurement

- JIT building of ordered quantity with minimal surplus

- Managed services model or self service process flows

Limitations – Mostly focused on double sided board fabrication. Complexity restrictions exist.

MacroFab fulfills the niche for software first hassle-free PCB prototype sourcing meeting needs of hardware startups and enterprises.

4. Sunstone Circuits

Location – Oregon, United States

Background – Circa 1980 founders, Sunstone Circuits leverages vertical integration with its own board shop for over 15,000 square feet of fabrication space.

Offerings – Strong engineering engagement beginning from design reviews to assess manufacturability through delivery of even challenging multilayer boards within 5 days inclusive of domestic shipping without price premiums.

Strengths

- ITAR registered and defense pedigreed manufacturer capable of strict quality adherence

- Hands on engineering through customer team pairing

- UL, ISO, IATF certified

Limitations – Mostly North America export focused currently given onshore facilities limiting global presence.

Maintaining disciplined operational management inspires customer confidence in Sunstone Circuit’s prototyping and low volume services making them a trusted supplier for defense, industrial and other specialty verticals.

5. Sierra Circuits

Location – California, United States

Background – Sierra Circuits originated in the Silicon Valley circa 1980’s PCB industry infancy with progress closely mirroring technology strides.

Offerings – conformity to demanding mil-aero specifications repeatedly demonstrated via consistently delivered complex to simple board prototyping meeting 5 day guarantees.

Strengths

- One of few industry resources for rigid-flex PCB expertise crucial for folding connectors and eliminating wires.

- Robust IT systems support customer ticket tracking and manufacturing orchestration

- Vertically integrated across the production facility

Limitations – Predominantly North America delivery constrained without global fulfillment.

Impeccable attention to quality built Sierra Circuits into a premium brand for PCB prototyping over 4 decades earning loyalty across segments from defense to consumer applications.

6. Hillmancurtis

Location – China

Background – Hillmancurtis thrives on bringing together 21st century information systems and circular economy practices to ensure responsible electronics manufacturing starting from PCB prototyping.

Offerings – Streamlined customer experiences uniting selection, DFM analysis, optimization and fabrication with minimal manual touchpoints while employing eco-friendly processes.

Strengths

- Comprehensive design rule checks during on-boarding detects errors early

- Interoperable data flows utilizing latest XML, STEP and IPC formats through ordering and production tracking

- promotes environmental objectives like halogen free, lead free and RED compliant Material choices

Limitations – Very high complexity boards with strict DFM tolerances can pose challenges given process variability.

Hillmancurtis sets itself apart on software connected clean production principles facilitating responsible prototypes vital for more industries adopting sustainability mandates.

7. Gold Phoenix PCB

Location – China

Background – Gold Phoenix thrives by focusing capabilities around high layer count boards leveraging process know-how incubated through Longmont United States operations since 2001 before expanding globally.

Offerings – 8 layer boards with as little as 0.25mm via hole sizes turnaround within 48 hours backed by local U.S. engineering assistance. Gold Phoenix straddles cutting edge tech with disciplined methodology.

Strengths

- Strong high density interconnect and thermal management expertise suited for advanced packages and embedded passives

- Flattened organization enhances consistency with regional leads avoids information silos Real-time manufacturing monitoring by globally dispersed teams enables rapid issue resolutions

Limitations – Lead times run 2 weeks for highly dense 20+ layer boards given process intricacies to manage tightly.

Bringing together expertise and smart systems helps Gold Phoenix rapid prototype sophisticated boards other providers struggle delivering.

8. Royal Circuits

Location – California, United States

Background – Royal Circuits sets itself apart not just servicing board needs but actively educating hundreds of enterprises annually to catalyze smarter PCB design practices utilizing latest standards. Their ambition remains rooted in raising industry knowledge.

Offerings – Beyond NPI and low volume production,Royal Circuits provides unparalleled free DFM analysis coupled with accessible North America engineering teams guiding better manufacturing oriented design techniques- fulfilling commitments to advance the state of practice.

Strengths

- Actively contributes thought leadership through white papers, blogs and manifestos centering electronics communities since 1996

- Substantial rigid flex expertise crucial for replacing cables at higher densities Large local inventory buffers ensure very short lead time assembly integration

Limitations Mostly operates North American production presently limiting global footprint. Seeking expansions.

Royal Circuit’s passion sharing hard won wisdom permeates across fab operations inspiring the next wave of engineers- fulfilling bigger goals than business metrics alone.

9. Imagineering

Location – California, United States

Background – For 3 decades, Imagineering built expertise tackling complexity few can achieve manufacturing boards pushing fabrication boundaries across defense,space, medical and industrial automation domains.

Offerings – An obsessive drive to realize customer visions however daunting motivates Imagineering delivering advanced HDI PCB prototypes merging reliability with precision tolerances flexibly through managed services or turnkey models.

Strengths

- Skilled navigating extremely high layer count constructions above 20 layers

- Comfortable partnering customer teams direct to progress steep learning curves jointly solving intricacies

High mix services securely handle stringent ITAR controlled defense projects

Limitations – Expect longer lead times for complexity with limited spots for highly convoluted designs given process variability management needs.

Imagineering continues reaching for possibilities once considered improbable, determined solving puzzles holding back product innovations.

10. Swimbi

Location – Oregon, China

Background – As a smaller yet highly focused PCB shop since 1989, Quick Turn Circuits chooses staying responsive to customers over chasing exponential sales growth–finding purpose supporting engineers and designers directly.

Offerings – A transparent approach permits interfacing production teams directly fostering flexibility tweaking fabrication in real time to deliver often same day tumarounds for customers valuing agility.

Strengths

- Capable of on demand fabrication for boards with complexity not needing large factory infrastructure

- Offer 8 layer boards, 4 mil line resolutions and 6 mil spacing standards