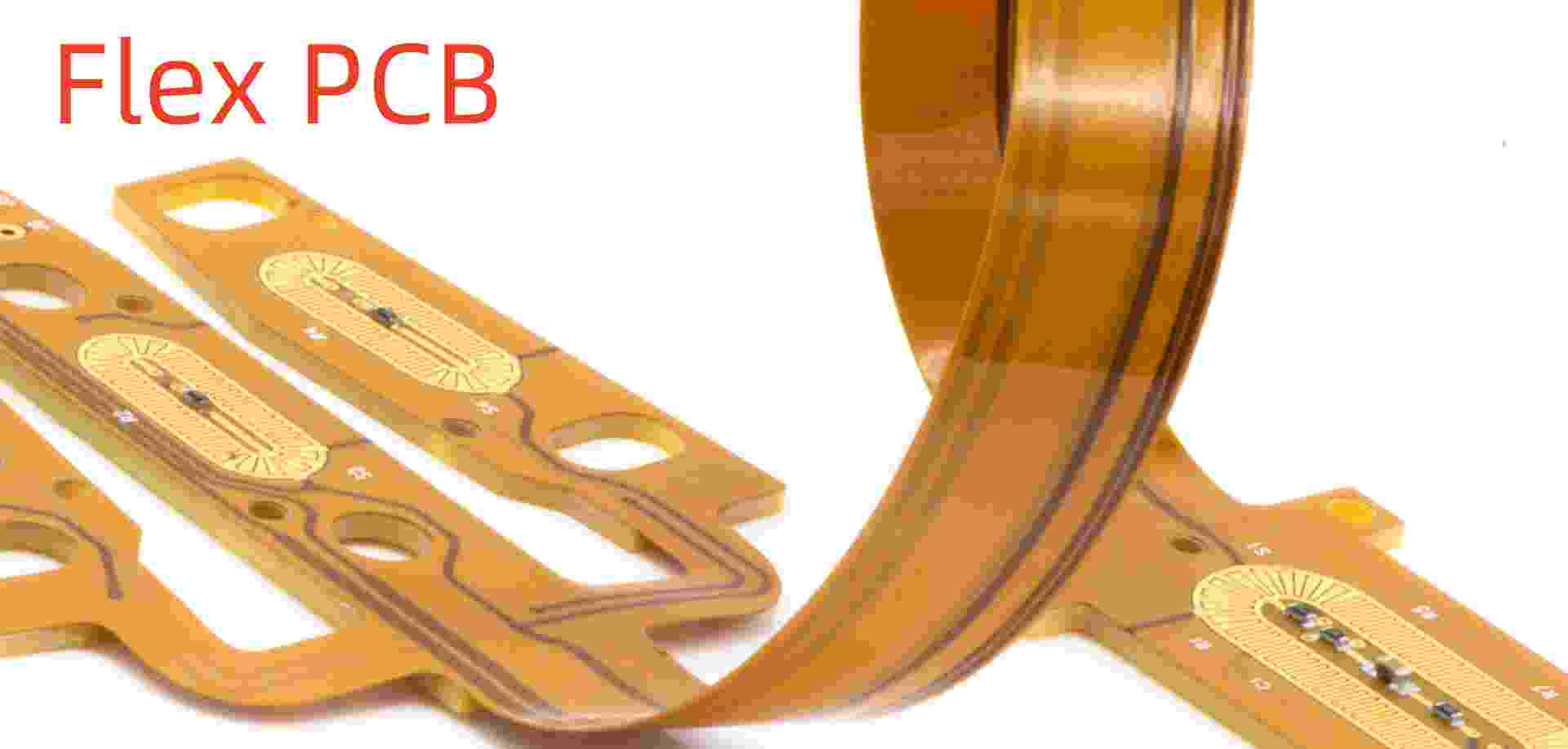

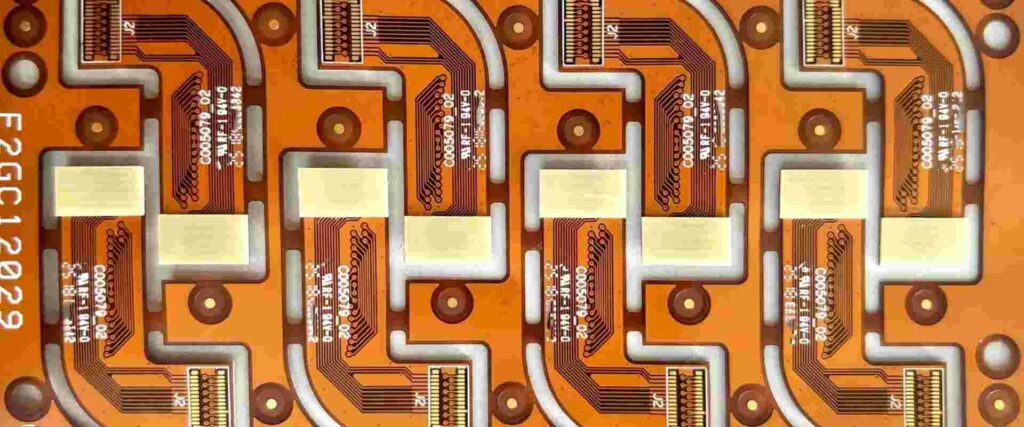

Flexible printed circuits (FPCs) offer unique advantages over rigid boards for many electronics applications. Flex circuits can bend, twist, and flex dynamically to interconnect components in confined spaces. Leading flex PCB manufacturers enable innovations across consumer gadgets, wearables, automotive electronics, aerospace systems, medical devices, robotics, and more through precision flex fabrication.

Selecting reliable flex circuit suppliers requires reviewing expertise across challenging flexible PCB processes. Here are 20 of the most capable flex PCB manufacturers serving customers worldwide:

1. Flexium Interconnect

- Headquarters: Zhuhai, China

- Founded: 2000

- Capabilities: Ultra-fine line flex, rigid-flex

- Facilities: China, Serbia, Mexico

- Certifications: IATF 16949, AS9100

- Clients: Consumer electronics, automotive, medical

- Volume Capacity: >20 million flex PCBs monthly

2. ZDT

- Headquarters: Shenzhen, China

- Founded: 1999

- Capabilities: Rigid-flex, HDI flex, flexible cabling

- Facilities: China

- Certifications: ISO 9001, ISO 14001, IATF 16949

- Clients: Automotive, industrial, consumer electronics

- Volume Capacity: >15 million flex PCBs monthly

3. RayMing Technology

- Headquarters: Suzhou, China

- Founded: 2001

- Capabilities: Rigid-flex, flexible cabling, roll-to-roll flex

- Facilities: China

- Certifications: ISO 9001, TS 16949, ISO 14001

- Clients: Aerospace, automotive, medical, industrial

- Volume Capacity: >5 million flex PCBs monthly

4. Multi-Fineline Electronix (MFLEX)

- Headquarters: Irvine, USA

- Founded: 1984

- Capabilities: High-density interconnect flex

- Facilities: China, Malaysia, Massachusetts, California

- Certifications: ISO 9001, ISO 13485, AS9100

- Clients: Datacomm, telecom, automotive, medical

- Volume Capacity: >70 million flex PCBs monthly

5. Flexium

- Headquarters: Milpitas, USA

- Founded: 1998

- Capabilities: HDI flex, rigid-flex, roll-to-roll processing

- Facilities: Asia, Poland, USA

- Certifications: IATF 16949, AS9100

- Clients: Consumer electronics, computing

- Volume Capacity: >20 million flex PCBs monthly

6. Career Technologies

- Headquarters: Taiwan

- Founded: 1999

- Capabilities: Multilayer rigid-flex, printed electronics

- Facilities: Taiwan, China

- Certifications: ISO 9001, IATF 16949

- Clients: Consumer electronics, automotive, IoT

- Volume Capacity: >30 million flex PCBs monthly

7. Flex (Flextronics)

- Headquarters: Singapore

- Founded: 1990

- Capabilities: HDI flex and rigid-flex

- Facilities: Global

- Certifications: ISO 14001, ISO 13485, AS9100

- Clients: Industrial, automotive, health solutions

- Volume Capacity: >25 million flex PCBs monthly

8. SUMITOMO FLEX

- Headquarters: Japan

- Founded: 1956

- Capabilities: Flex-rigid PCBs, multi-layer flex

- Facilities: Japan, Vietnam, Lithuania

- Certifications: IATF 16949, ISO 14001

- Clients: Automotive, industrial equipment, healthcare

- Volume Capacity: >15 million flex PCBs monthly

9. Flexium Interconnect Korea

- Headquarters: Korea

- Founded: 1999

- Capabilities: Ultra-fine line flex circuits

- Facilities: Korea

- Certifications: IATF 16949, ISO 9001

- Clients: Consumer electronics, automotive

- Volume Capacity: >8 million flex PCBs monthly

10. All Flex

- Headquarters: Minnesota, USA

- Founded: 1992

- Capabilities: Flexible heater circuits, EMS

- Facilities: USA, Malaysia

- Certifications: ISO 13485, ISO 9001, IATF 16949

- Clients: Medical, industrial, electronics

- Volume Capacity: >3 million flex PCBs monthly

11. Mina Technology Corporation

- Headquarters: Taiwan

- Founded: 1980

- Capabilities: HDI flex-rigid PCBs

- Facilities: Taiwan, China

- Certifications: ISO-9001, IATF 16949

- Clients: Automotive Electronics

- Volume Capacity: >6 million flex PCBs monthly

12. TTM Technologies (Asia Pacific)

- Headquarters: Asia Pacific

- Founded: 1998

- Capabilities: Rigid-flex PCBs, RF flexible circuits

- Facilities: China and Asia

- Certifications: ISO 9001, ISO 14001, ISO 13485

- Clients: Aerospace, medical, industrial, networking

- Volume Capacity: >35 million flex PCBs monthly

13. Lenthor Engineering

- Headquarters: California, USA

- Founded: 1991

- Capabilities: Flex and rigid-flex PCBs

- Facilities: California, Mexico

- Certifications: ISO 9001, AS9100, ITAR

- Clients: Military, aerospace, satellite, optical systems

- Volume Capacity: >1 million flex PCBs monthly

14. Compass Circuits

- Headquarters: UK

- Founded: 1989

- Capabilities: Prototyping and quickturn flex PCBs

- Facilities: UK

- Certifications: ISO 9001, UL

- Clients: Design engineers, startups, universities

- Volume Capacity: >50,000 flex PCBs monthly

15. Electronic Technologies Corporation (ETC)

- Headquarters: Wisconsin, USA

- Founded: 2000

- Capabilities: Prototype and quickturn flex circuits

- Facilities: Wisconsin, USA

- Certifications: ISO 9001

- Clients: Product Design, R&D

- Volume Capacity: >50,000 flex PCBs monthly

16. Flexible Circuit Technologies (FCT)

- Headquarters: Minnesota, USA

- Founded: 1982

- Capabilities: Quickturn flex and rigid-flex prototyping

- Facilities: Minnesota, USA

- Certifications: ISO 9001

- Clients: Engineers, startups, universities

- Volume Capacity: >75,000 flex PCBs monthly

17. Century Circuits

- Headquarters: Missouri, USA

- Founded: 1970

- Capabilities: Rigid-flex PCB prototypes

- Facilities: Missouri, USA

- Certifications: ISO 9001

- Clients: engineers, startups

- Volume Capacity: >25,000 flex PCBs monthly

18. Royal Flex Circuits

- Headquarters: California, USA

- Founded: 1976

- Capabilities: Flex and rigid-flex prototyping

- Facilities: California, USA

- Certifications: ISO 9001

- Clients: Engineers, designers, academics

- Volume Capacity: >25,000 flex PCBs monthly

19. Smoltek

- Headquarters: Sweden

- Founded: 2011

- Capabilities: Carbon nanomembrane flex circuits

- Facilities: Sweden, California

- Certifications: ISO 9001

- Clients: Aerospace, industrial, medtech

- Volume Capacity: >10,000 flex PCBs monthly

20. American Standard Circuits

- Headquarters: Illinois, USA

- Founded: 1967

- Capabilities: Flex and rigid-flex PCB prototypes

- Facilities: Multiple in USA

- Certifications: ISO 9001

- Clients: Product Design, R&D

- Volume Capacity: >75,000 flex PCBs monthly

Conclusion

This list highlights leading global flex PCB manufacturers serving diverse markets with innovative flexible circuit solutions. Their capabilities and expertise in high-density interconnect, rigid-flex, and specialty flex applications enable the sophisticated flex circuits empowering modern devices. Continued flex PCB advancements will support electronics innovation across industries.

FQA

What are the most common materials used as the flexible substrate in flex PCBs?

Common flex circuit dielectric materials include polyimide, polyester, polyethylene naphthalate, acrylic, and polyetherimide films. These provide flexibility while also meeting thermal and electrical needs.

What are some key differences between single and double sided flex circuits?

Single sided flex PCBs have conductors only on one side while double sided flex allows conductors on both sides, enabling higher component densities. Multilayer flex circuits also exist.

What are some of the most demanding performance requirements flex PCBs must meet?

Critical flex performance parameters can include flexibility cycles, dynamic flex endurance, bending radii stability, dielectric strength, impedance tolerances, high frequency signal quality, and thermal management.

What trends are influencing flex PCB design and manufacturing?

Trends include miniaturization, higher densities, thinner dielectrics, flexible hybrid electronics, flexible displays, printed electronics, and embedded passives and actives.

What role does computer aided engineering (CAE) analysis play in flex PCB design?

CAE tools like finite element analysis and 3D modeling help predict stresses, thermal response, and mechanical behaviors to optimize flex circuit design performance.