Introduction

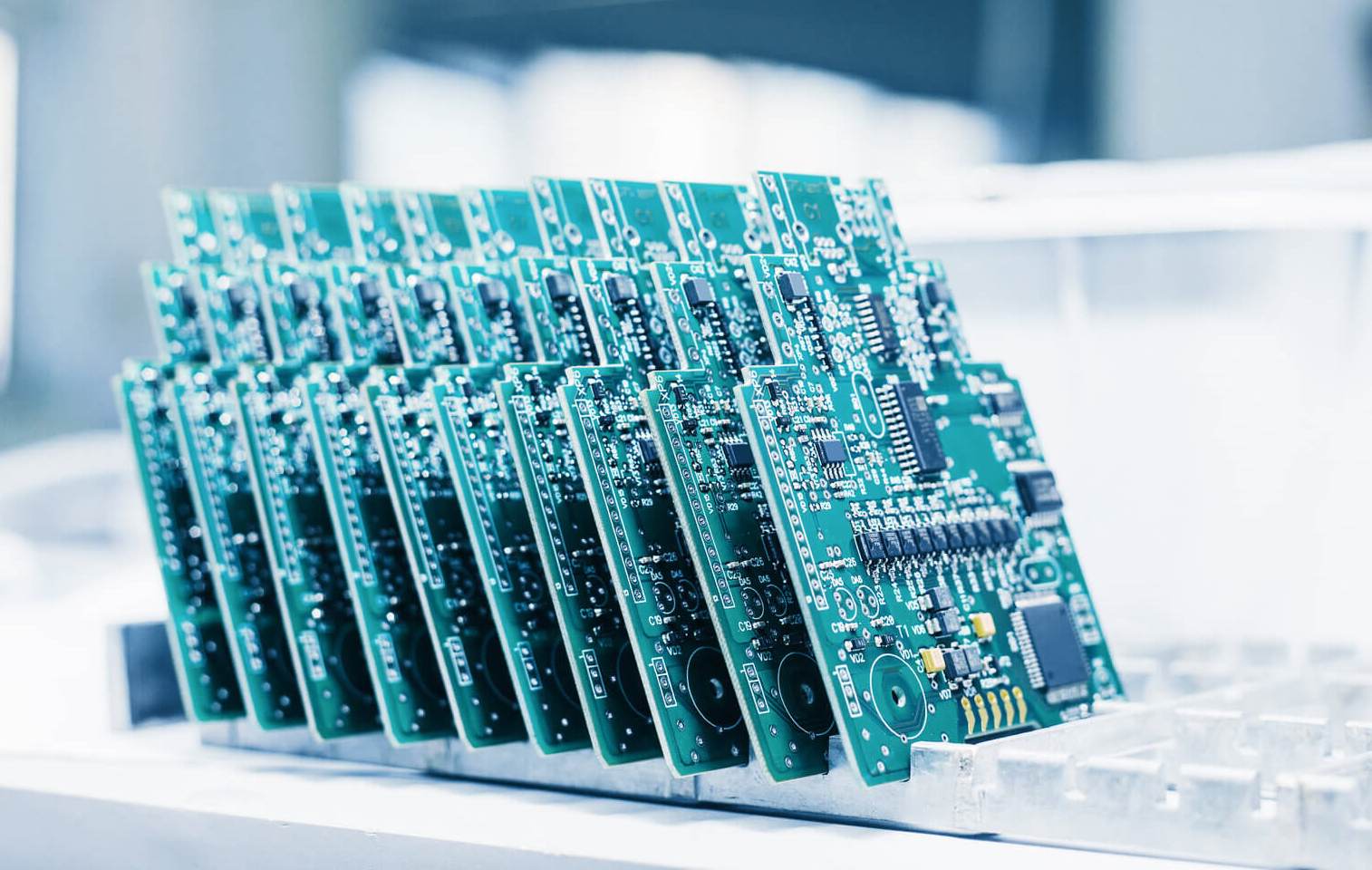

Printed circuit boards (PCBs) serve as the backbone for any electronics product. From a prototype board to a complex multilayered board with high-speed routing, PCBs play an essential role in turning an electronic design into reality. With the right PCB fabrication partner, you can ensure your circuit boards are manufactured accurately and on time.

RAYPCB is a professional PCB manufacturer based in China that offers quick-turn PCB prototyping and small-to-medium volume PCB production services. With over 10 years of experience fabricating PCBs, RAYPCB has streamlined their ordering system to make the PCB quoting and ordering process straightforward for customers worldwide.

This article will walk you through the key steps involved in obtaining a PCB fabrication quote and placing an order on the RAYPCB website. We’ll explore the PCB capabilities RAYPCB offers, how to create an account and upload your Gerber files, select the appropriate PCB options, get a fabrication quote, place your order, and track your PCB manufacturing and delivery. Let’s get started!

Overview of RAYPCB’s PCB Capabilities

RAYPCB provides a comprehensive range of PCB fabrication and assembly services suitable for prototyping, low-volume, and mid-volume production quantities.

Here are some of RAYPCB’s key capabilities:

PCB Substrate Materials

- FR-4 substrate (high Tg 170°C, standard Tg 140°C, and halogen-free)

- High-frequency materials – Rogers, Taconic, Arlon

- Aluminum, IMS, and other metal core PCBs

- Flexible & rigid-flex PCBs

Layer Count

- Single layer, double layer, and multilayer PCBs up to 28 layers

Minimum Trace/Space

- 6/6 mil (0.15/0.15mm) trace/space for outer layers

- 8/8 mil (0.20/0.20mm) trace/space for inner layers

Finished Copper Thickness

- 1oz (35μm) to 2oz (70μm) finished copper weight

PCB Thickness

- 0.4mm to 5mm thickness with ±10% tolerance

Hole Sizes/PTH (Plated Through Holes)

- 0.15mm to 0.60mm hole sizes with ±0.025mm tolerance

- 0.20mm minimum annular ring

- PTH, non-PTH, and microvias

Solder Mask & Silkscreen

- LPI (Liquid Photo Imageable) solder mask in various colors

- Screen printed white silkscreen legend

Surface Finishes

- HASL, immersion silver, immersion gold, immersion tin, ENIG, and OSP surface finishes

Panel Sizes

- Maximum dimension: 546mm x 610mm (21.5in x 24in)

- No minimum panel requirements

PCB Production Lead Times

- 24 hours for prototyping quantities

- 5-7 working days for small batches (≤1000 pcs)

- 8-15 working days for larger quantities

With these capabilities, RAYPCB can support PCB needs ranging from simple single-sided boards to advanced multilayer designs. They cater well to the prototyping, R&D, and medium volume production market segments.

Creating a RAYPCB Account

The first step in ordering PCBs from RAYPCB is to create an account on their website. This allows you to access PCB quoting, upload design files, save your PCB orders and quotes, select payment methods, and track order status.

Creating an account is quick and easy. Just follow these steps:

- Go to www.raypcb.com and click “Join Free” in the top right corner.

- Enter your email address and create a password for your account.

- Fill in some basic details – name, company name, phone number, and address.

- Select your preferred currency – USD or Chinese Yuan.

- Check your email inbox for a confirmation message from RAYPCB and click the link to activate your account.

Once your account is activated, you can log in on the RAYPCB website with your email and password. Now you are ready to upload your PCB design files and request a fabrication quote.

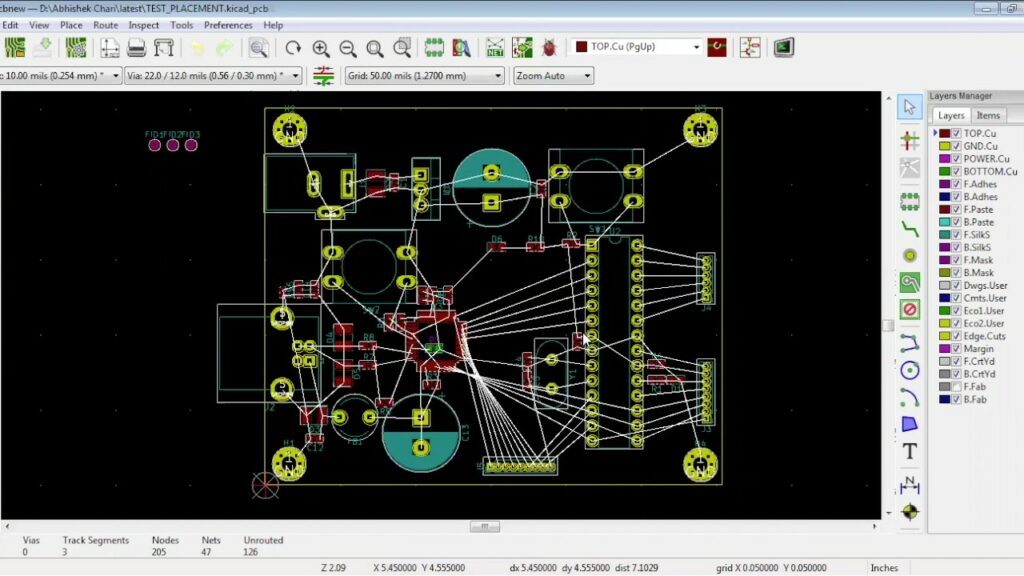

Uploading Your PCB Design Files

To generate a fabrication quote, RAYPCB needs your complete PCB design files. This includes:

- Gerber files – the layered PCB fabrication data files generated by your EDA tool.

- Drill files – NC drill files defining the hole sizes and locations.

- Assembly files (optional) – BOM, pick and place, etc. for turnkey PCB assembly.

- Mechanical drawings (optional) – board outline, stackup, layers, etc.

You will upload these files to RAYPCB using their online Gerber file checker tool. This allows RAYPCB to validate your files before providing a fabrication quote.

Follow these steps to upload your PCB design files to RAYPCB:

- Log into your RAYPCB account and click “Quote Now” or “Upload Gerber” in the top menu bar.

- On the Upload page, click “Browse” and select the Gerber files from your computer.

- Upload your drill files using the second browse button.

- If ordering PCB assembly, upload your assembly files like BOM, CPL, etc.

- Add any mechanical drawings or fabrication notes.

- Enter your name, email, and phone number.

- Click “Upload” to submit your files to RAYPCB.

The file checker will validate your PCB data and send you a confirmation email once complete. If any errors are found, RAYPCB can assist you in correcting them. Otherwise, your files are ready for quoting!

Obtaining a PCB Fabrication Quote

Once your Gerber files pass validation, RAYPCB can generate an instant online quotation with pricing, lead times, and other details.

To get your PCB quote:

- After uploading your Gerber files successfully, click “Go to Quote”

- Review the PCB specifications extracted from your data:

- Layer count

- Board dimensions

- PCB quantity

- Default PCB thickness, copper weight, and fabrication capabilities

- Enter the number of PCBs required under “Quantity”

- Select any special PCB capabilities if needed:

- PCB thickness

- Layer count

- Blind/buried vias

- Higher trace/space

- Tight tolerances

- Alt. substrate (Rogers, IMS)

- HDI/micrvias

- Heavy copper

- Special surface finish

- Impedance control

- Stiffeners

- Castellated holes

- Carbon ink

- Beveling/routing

- Special testing

- Special tooling

- Gold fingers

- Via plugging/tents

- Press-fit pins

- Peelable solder mask

- Flex/rigid-flex PCBs

- Choose your preferred surface finish: HASL, immersion silver, immersion gold, ENIG, etc.

- Select any special assembly services:

- SMT assembly

- Through-hole assembly

- Box build/cables

- Conformal coating

- Functional testing

- Programming

- Enter any special instructions or notes for the PCB fab and assembly.

- Click “Save to Cart” to generate your free instant quotation.

The RAYPCB ordering system will analyze your design files, selected capabilities, quantity, and assembly requirements to provide a detailed fabrication and assembly quote.

In addition to online pricing, you will receive:

- Recommended PCB stackup

- Review of your design files and CAM data

- Assembly quotes for SMT, THT, functional testing, etc.

- DFM review and recommendations

- Lead time estimates

- Shipping charges

Carefully review the quotation details and be sure all your PCB requirements have been captured accurately. If any revisions are needed, you can adjust your PCB specifications and instantly regenerate the quote.

Once you are satisfied with the free quotation, continue the order submission process.

Placing Your PCB Order

When ready to place your order, there are just a few more steps to finalize your purchase:

- Confirm order – Review the complete quotation details and reorder specifications. Click “Confirm Order” to proceed.

- Select payment method – Choose PayPal or credit card online payment. Bank transfers are also accepted.

- Complete payment – Follow the prompts to securely complete your payment.

- Upload manufacturing files – Upload your final Gerber, drill, assembly, and other manufacturing files if any changes were made.

- Sign NDA – Review and electronically sign the NDA to protect your design files.

- Submit order – Review all details again and click “Submit Order” to finalize the purchase.

That’s it! RAYPCB will send an order confirmation email with your payment receipt and next steps. Your PCB order will be dispatched to manufacturing and assembly (if applicable).

Now let’s look at tracking the manufacturing and delivery status.

Tracking PCB Order Status

RAYPCB offers full supply chain visibility and updates throughout the fabrication, assembly, and shipping process.

You can monitor your order status directly through your RAYPCB account.

Manufacturing Status Updates

After submitting your order, you will receive regular email updates on the manufacturing status:

- Order confirmed

- Gerber data review completed

- Materials procured

- PCB fabrication started

- PCB fabrication completed

- PCB assembly started (if ordered)

- PCB assembly completed

- Final testing and QA

- Order ready for shipment

You can also log into your RAYPCB account and check the order status page for real-time progress.

Shipping and Delivery Tracking

Once your PCB order leaves the factory, you will receive a tracking number for the parcel. Monitor the tracking status through:

- Order status page in your RAYPCB account

- Email and SMS text updates from RAYPCB on shipment status

- Carrier website using the provided tracking number

The tracking updates will show the parcel’s progress through customs, handoffs between carriers, out for delivery, and final delivery confirmation.

You will receive additional notification once your PCBs have been successfully delivered.

RAYPCB PCB Ordering FAQ

Below are answers to some frequently asked questions about ordering PCBs from RAYPCB:

How long does it take to get a PCB quote from RAYPCB?

You will receive an instant online quotation within minutes after uploading your Gerber files and completing the order specifications.

What Gerber viewer and CAM tools does RAYPCB support?

RAYPCB accepts Gerber files from all major PCB CAD tools including Altium Designer, Eagle, OrCAD, Pads, KiCAD, Allegro, Mentor, and others.

Can I get free DFM analysis on my PCB files?

Yes, RAYPCB will review your design files at no charge and provide recommendations to improve manufacturing yield. Their engineers can help resolve any issues.

Does RAYPCB do PCB assembly?

Yes. RAYPCB offers full turnkey PCB assembly services including SMT assembly, through-hole assembly, functional testing, programming, and complete box build. You can request assembly quotes along with your board fabrication quotes.

How can I pay for my PCB order?

RAYPCB accepts online payments via credit card, PayPal, wire transfer, Western Union, and WebMoney. You will pay upon order submission before manufacturing starts.

Can I track the manufacturing status of my PCB order?

Yes, RAYPCB provides full supply chain visibility and regular email status updates throughout the fabrication, assembly, and shipping process. Check your order status online anytime.

How long does the PCB shipping take?

RAYPCB offers multiple international shipping options including DHL, Fedex, TNT, UPS. Shipping time is 3-7 days depending on quantity and destination.

Does RAYPCB offer engineering and technical support?

Yes. RAYPCB has an experienced engineering team that can provide PCB design, DFM, assembly, and troubleshooting assistance before and after you place your order.

Conclusion

We have walked through the complete process of obtaining PCB fabrication quotes from RAYPCB and ordering your boards through their online system. From creating an account to uploading design files, selecting PCB specifications, acquiring instant quotes, placing orders, and tracking delivery status, RAYPCB aims to make ordering prototype through medium-volume PCB production straightforward for customers worldwide.

With over a decade of experience manufacturing PCBs, RAYPCB is an excellent choice for your PCB prototyping and small-batch production needs. Their passionate engineering team and advanced manufacturing capabilities can bring your designs to life quickly and accurately.

We hope this step-by-step guide to exploring and placing your first order on the RAYPCB website gives you the knowledge to proceed with confidence. Feel free to contact the RAYPCB team with any additional questions as you start using their PCB fabrication and assembly services.