SMT

-

Read more: What is The Best High-Precision Solder Paste Printer for SMT ?

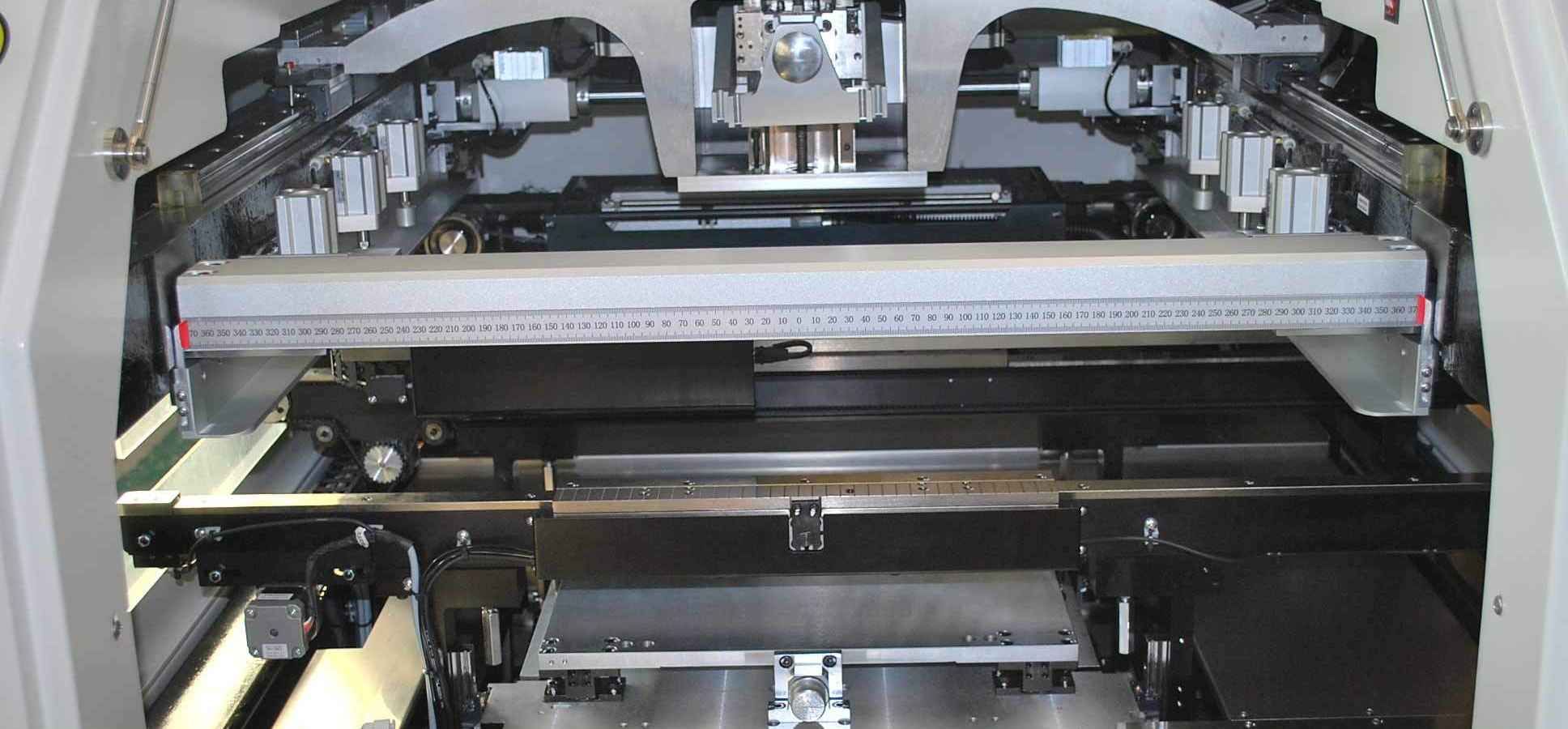

Read more: What is The Best High-Precision Solder Paste Printer for SMT ?Solder paste printing constitutes a pivotal first step in the surface mount assembly process workflow responsible for accurate and repeatable transfer of solder paste from stencil to PCB pads, governing subsequent solder joint quality. With shrinking component sizes, finer pitches and tighter tolerances becoming prevalent, selection of an appropriately precise … Read more

-

Read more: What does a solder paste stencil do?(Types with Process)

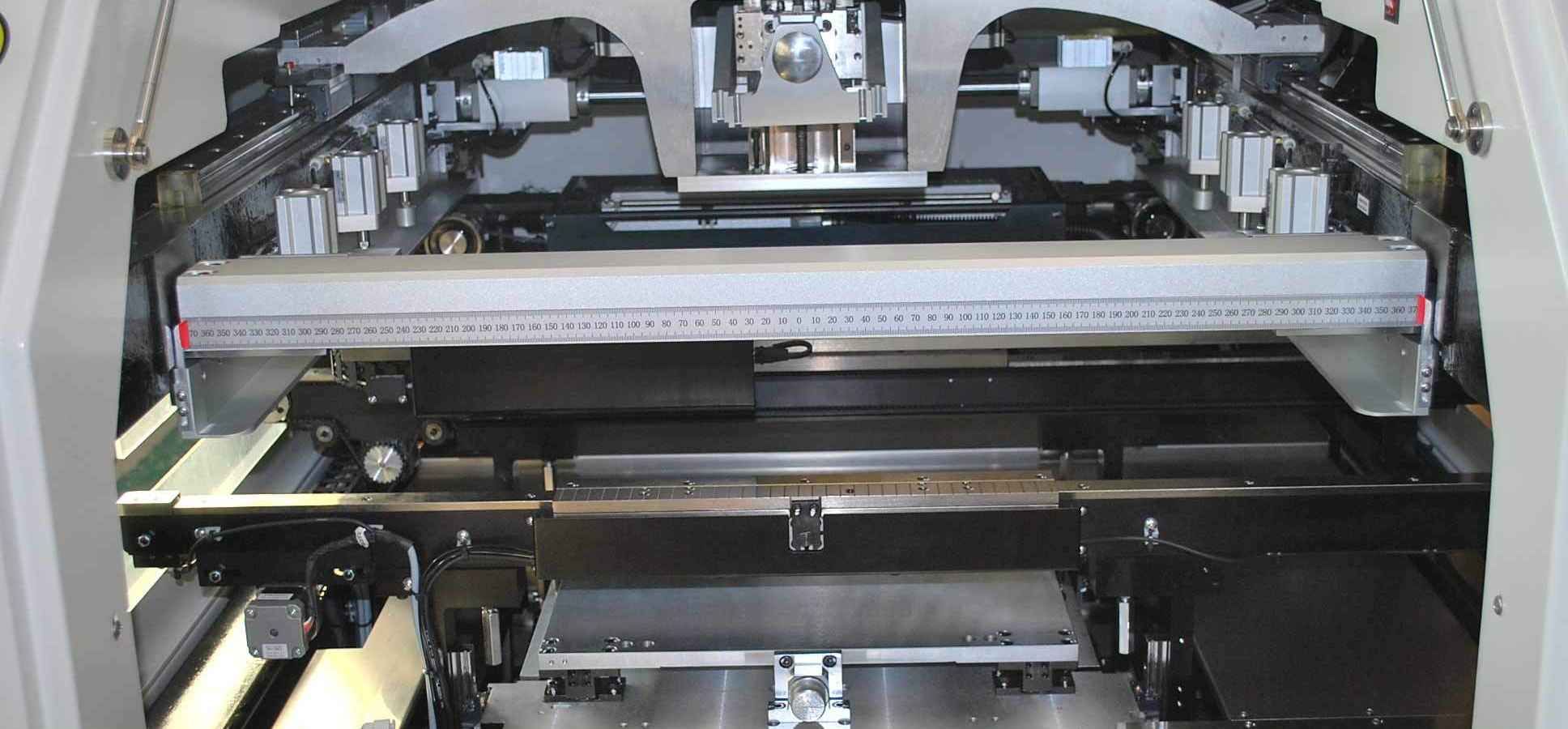

Read more: What does a solder paste stencil do?(Types with Process)A solder paste stencil is a key consumable used in printed circuit board assembly for applying precise and uniform solder paste deposits onto pads prior to surface mount component placement. This article provides an extensive overview covering stencil types, manufacturing methods, working principles, key functionalities, parameters and performance factors involved … Read more

-

What Temperature is Best for Soldering?

Posted by

–

Read more: What Temperature is Best for Soldering?

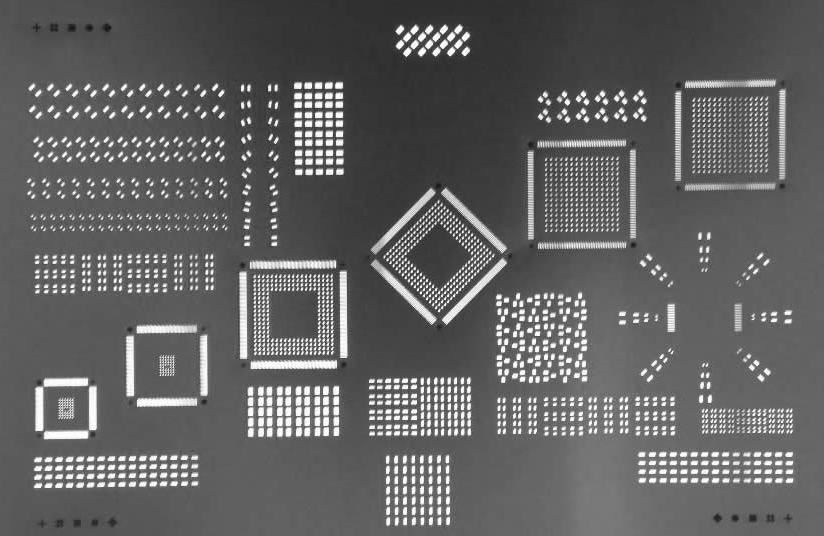

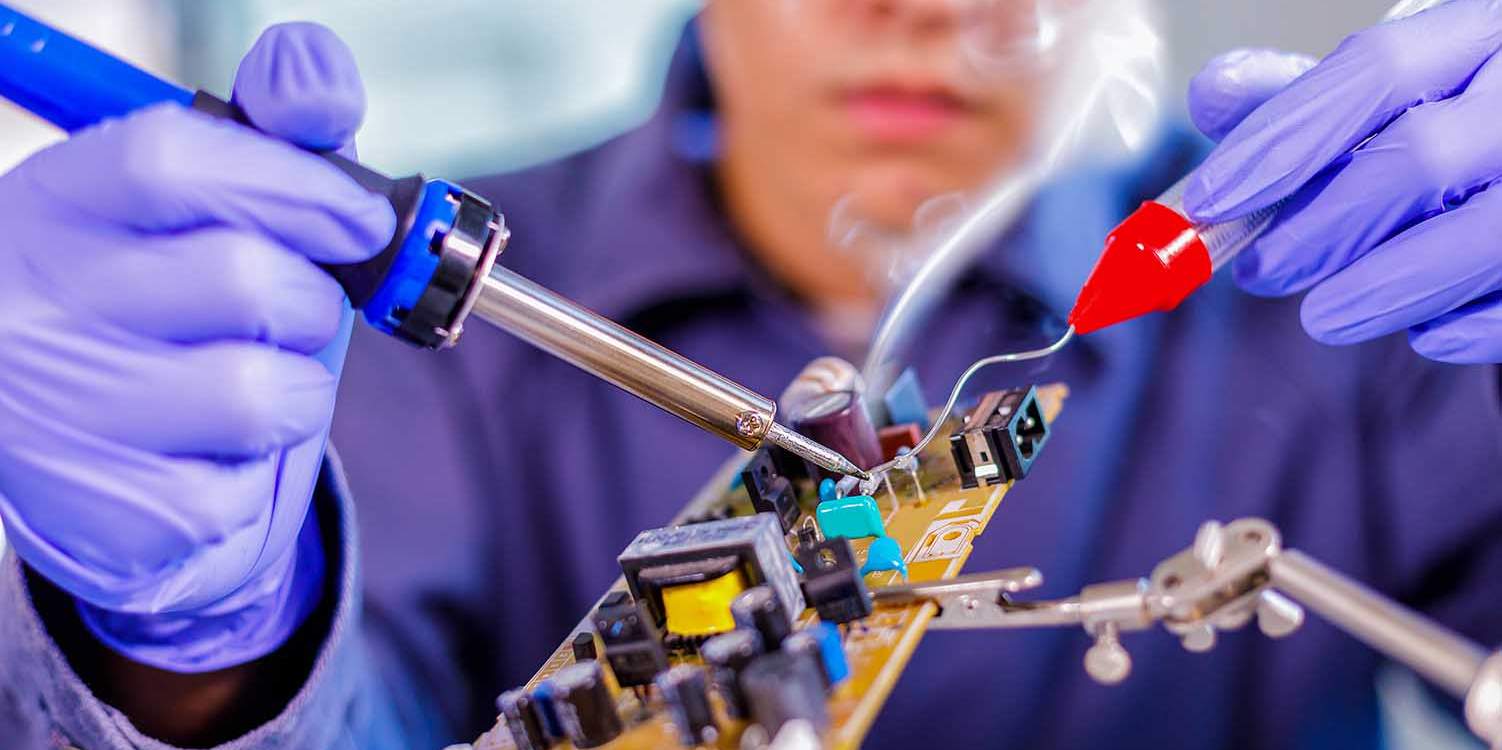

Read more: What Temperature is Best for Soldering?Soldering is a process used to join metal components together by melting and applying a filler metal (solder) to form a strong metallic bond between the parts. Choosing the right soldering temperature is crucial for creating secure, long-lasting solder joints. The optimum temperature depends on the metals being soldered, the … Read more

-

How do you make a PCB Stainless Steel Stencil ?

Posted by

–

Read more: How do you make a PCB Stainless Steel Stencil ?

Read more: How do you make a PCB Stainless Steel Stencil ?Printed circuit board (PCB) stencils comprise thin metal sheets containing cutouts used for applying solder paste onto pads during surface mount assembly. Stainless steel offers an ideal stencil material given durability, chemical resistance and ease of cleaning necessary for repeat usage over PCB production runs. Various methods exist for manufacturing … Read more

-

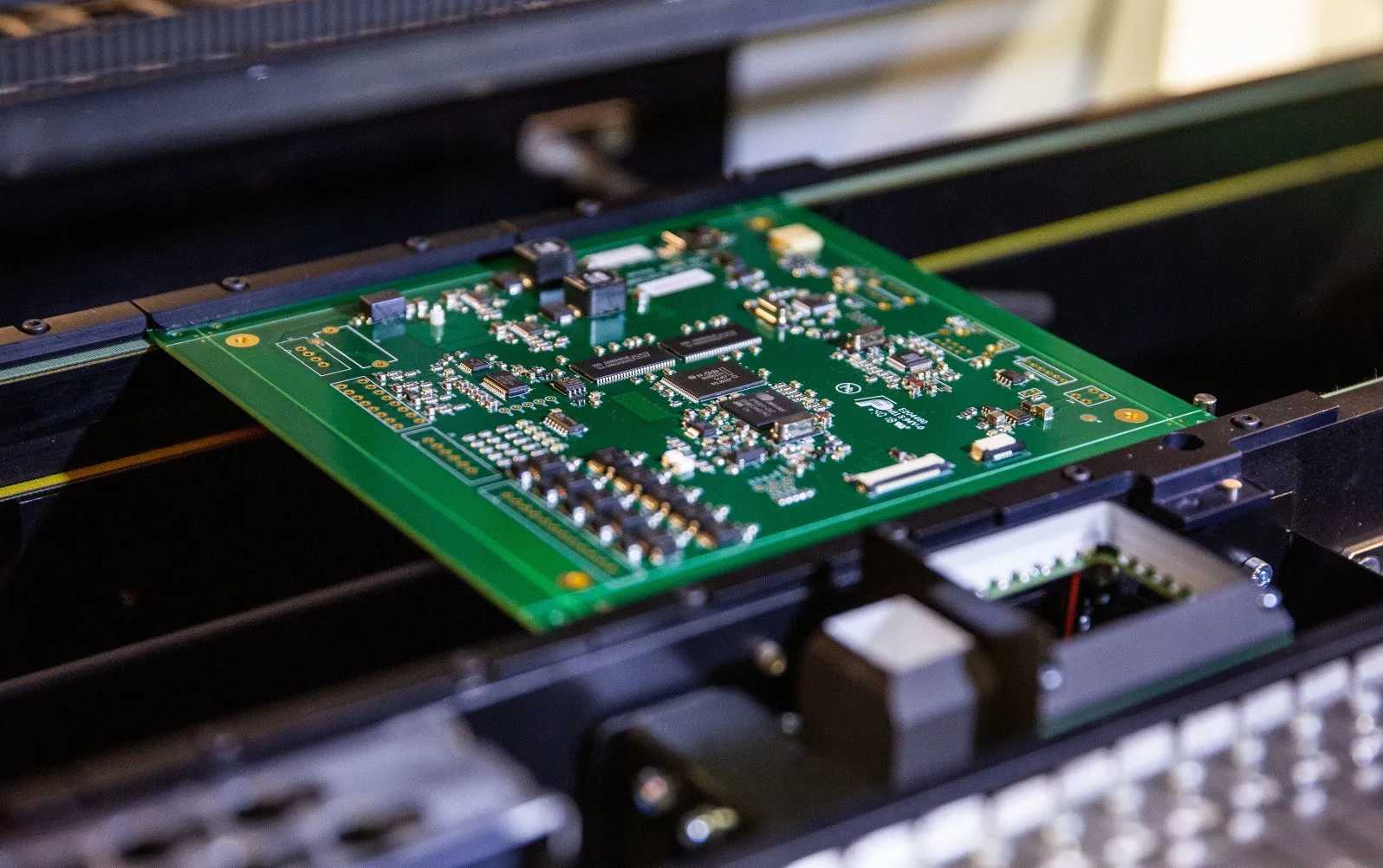

What is surface mount technology?

Posted by

–

Read more: What is surface mount technology?

Read more: What is surface mount technology?Surface mount technology (SMT) refers to the method of mounting electronic components directly onto the surface of a printed circuit board (PCB) without through-hole leads. Instead, surface mount components have terminations that solder directly to flat copper pads on the outer surfaces of the PCB. SMT transformed electronics manufacturing by … Read more

-

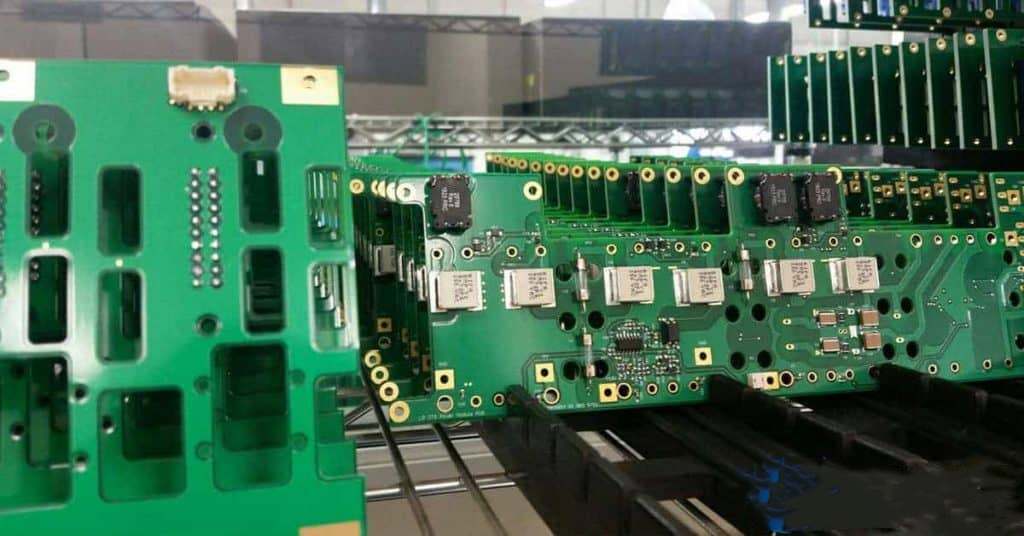

What is Through-hole PCB Assembly?

Posted by

–

Read more: What is Through-hole PCB Assembly?

Read more: What is Through-hole PCB Assembly?Through-hole technology refers to the mounting of electronic components on printed circuit boards (PCBs) using terminated leads called pins that pass completely through holes drilled in the board. The protruding pins are then soldered on the opposite side to form both mechanical and electrical connections. This article provides a detailed … Read more

-

What is One-Stop Full Turnkey PCB Assembly ?

Posted by

–

Read more: What is One-Stop Full Turnkey PCB Assembly ?

Read more: What is One-Stop Full Turnkey PCB Assembly ?For companies developing electronic products, outsourcing Printed Circuit Board (PCB) assembly to an External Manufacturing Supplier (EMS) provider is an attractive option. Finding an EMS partner who can provide a comprehensive “one-stop” turnkey assembly solution delivers many benefits through consolidation and simplification. This article will explain what turnkey PCB assembly … Read more

-

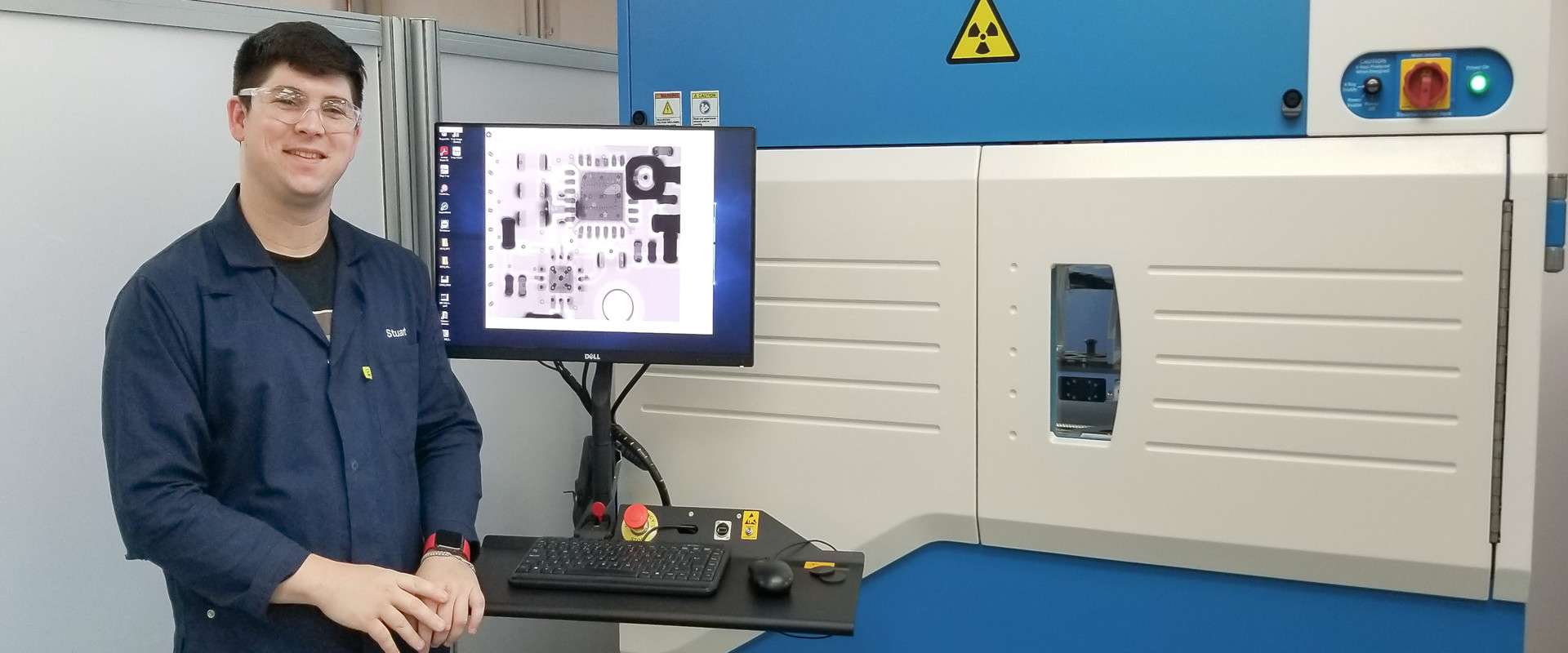

What Is PCB X-Ray Inspection?

Posted by

–

Read more: What Is PCB X-Ray Inspection?

Read more: What Is PCB X-Ray Inspection?Introduction Printed circuit boards (PCBs) integrate a wide array of electronic components and interconnects into a compact functional system. Ensuring the quality and reliability of PCB assembly requires thorough inspection to identify any defects introduced during the manufacturing process. Automated optical inspection (AOI) is commonly used but cannot visualize inside … Read more

-

What is Turnkey PCB Assembly ?

Posted by

–

Read more: What is Turnkey PCB Assembly ?

Read more: What is Turnkey PCB Assembly ?Printed circuit board (PCB) assembly involves soldering various electrical and electronic components like resistors, capacitors, ICs, connectors etc. onto a PCB to create a fully functional electronic circuit. Turnkey PCB assembly refers to outsourcing the entire assembly process to a specialized PCB assembly service provider. The assembly partner takes responsibility … Read more

-

What Does EMS Mean in Manufacturing?

Posted by

–

Read more: What Does EMS Mean in Manufacturing?

Read more: What Does EMS Mean in Manufacturing?Introduction EMS stands for Electronics Manufacturing Services. In the manufacturing industry, EMS providers are companies that design, assemble, produce and test electronic components and systems for OEMs (Original Equipment Manufacturers). The roles performed by EMS companies typically include: By outsourcing production to an EMS provider, OEMs can focus on their … Read more

Recent Posts

- Understanding the PCB Burn-in Testing Process in PCB Manufacturing!

- Unlock the Potential of Embedded PCB Assemblies for Improving the Performance of Electronics Devices

- What are the Advantages of Custom Cable Assembly to meet your bespoke needs?

- What are the benefits and limitations of custom PCB boards?

- What are the benefits of Prototype PCB manufacturing and why is it important?

Categories

- 3D Guides 2,663

- Components 4

- Design 22

- Electronics 20

- PCB 125

- SMT 27

Tag Cloud

There’s no content to show here yet.