For companies developing electronic products, outsourcing Printed Circuit Board (PCB) assembly to an External Manufacturing Supplier (EMS) provider is an attractive option. Finding an EMS partner who can provide a comprehensive “one-stop” turnkey assembly solution delivers many benefits through consolidation and simplification.

This article will explain what turnkey PCB assembly encompasses, discuss the advantages and disadvantages of a turnkey approach, review the capabilities required, and provide guidance on selecting the optimal turnkey assembly partner.

What is Turnkey PCB Assembly?

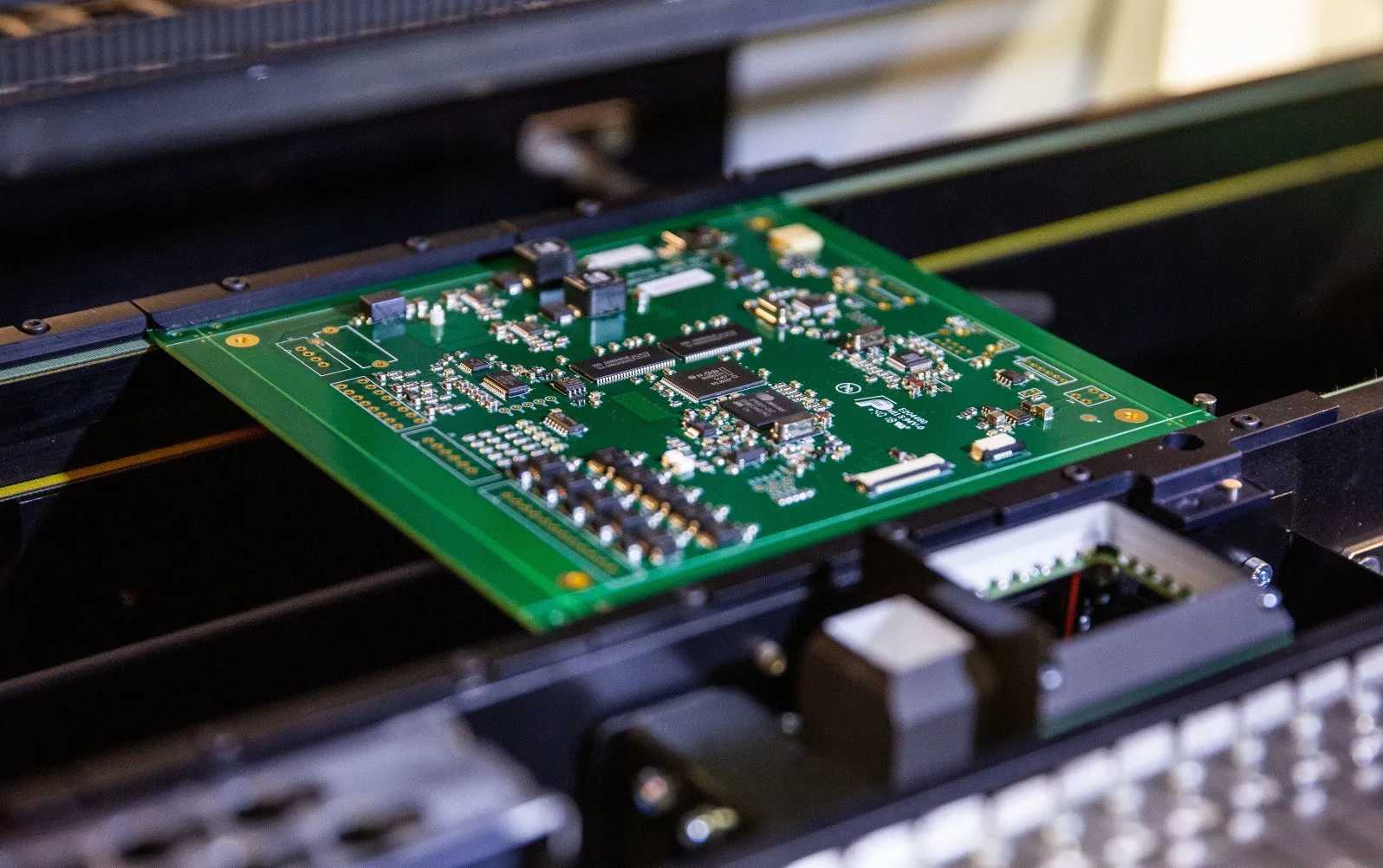

The term “turnkey” refers to an EMS provider who takes full ownership of managing all steps required to assemble finished printed circuit boards. This can include:

- Sourcing components

- Kitting parts

- Solder paste screening

- SMD assembly

- Through-hole assembly

- Cleaning

- Conformal coating

- Press-fit insertion

- Testing/inspection

- Logistics

By providing all assembly processes in one centralized location, turnkey assembly simplifies the supply chain and provides a consolidated point of quality control and responsiveness compared to managing multiple vendors.

Benefits of One-Stop Turnkey PCB Assembly

Choosing a full turnkey assembly partner brings a number of important benefits:

Single Point of Contact

- Simplify engineering, quality, and program management through one main supplier contact.

Streamlined Logistics

- Avoid coordinating data, components, and boards across multiple vendors.

Quicker Problem Resolution

- Issues can be rapidly identified and fixed when all steps are under one roof.

Quality Ownership

- Single vendor responsibility provides end-to-end quality assurance.

Improved Communication

- Eliminates complex multi-party alignment across fragmented assembly chain.

Flexibility and Synergy

- Turnkey vendor dynamically allocates resources across processes as needed.

Reduced Overhead

- Consolidating vendors decreases procurement work and supplier management.

Potential Cost Savings

- Turnkey efficiencies, shared overhead and pooled buy pricing can reduce total cost.

Faster Time to Market

- Parallelized processes, streamlined handoffs, and rapid feedback accelerate cycle times.

For complex assemblies, turnkey services simplify sourcing and production.

Challenges of Turnkey PCB Assembly

While providing major advantages, using a turnkey model also poses some potential risks or disadvantages to weigh:

Single Source Dependency

- Sole vendor liability if turnkey provider has issues or shutdowns.

Less Control and Visibility

- Reduced customer process auditing and monitoring access.

Agility Limitations

- Harder to shift specific processes to new suppliers in response to problems.

Volume Commitment

- Turnkey favors customers who provide steady medium-high volumes.

Potential Price Premium

- One-stop simplicity sometimes comes at a cost premium.

Non-Optimal Specialization

- No one vendor will be best-in-class at every assembly process.

Proprietary Constraints

- Turnkey provider may favor certain component brands they supply.

Quality Ownership Imbalance

- Design choices made without turnkey consultation can undermine quality.

The convenience of turnkey assembly trades off against some loss of control, flexibility, and customization ability.

Capabilities Required for Full Turnkey Assembly

To enable true one-stop PCB assembly, an EMS provider must have extensive capabilities:

SMT Assembly

- High speed SMD assembly lines with latest pick-and-place technology.

Through Hole Assembly

- Flexible through hole assembly workcells.

Component Sourcing

- Established global component procurement with authorized distributors.

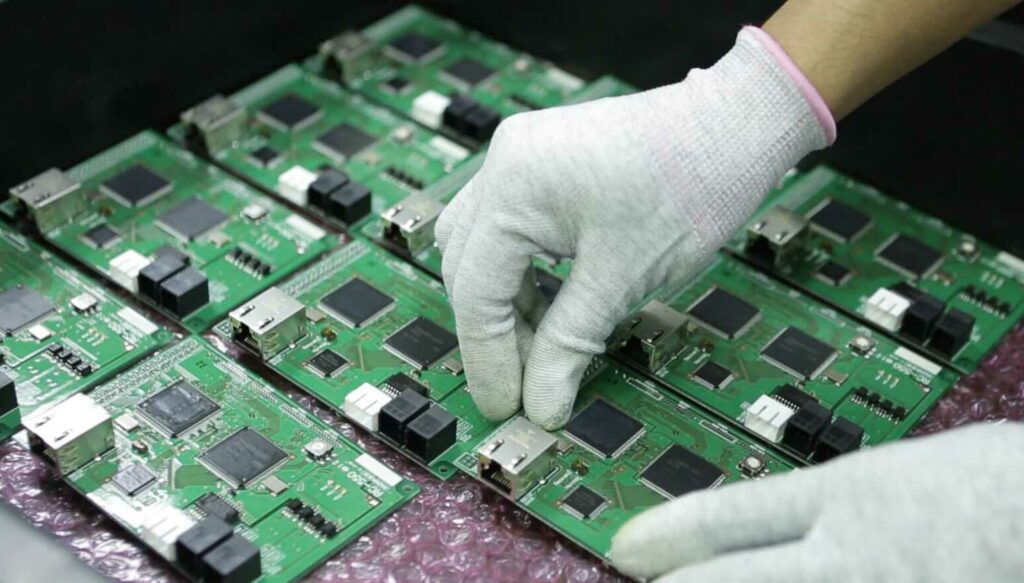

Kitting

- Advanced kitting to preprocess optimal component sets for production.

Test Development

- In-house test fixture design and programming expertise.

Testing/Inspection

- Comprehensive test and inspection equipment including ICT, AOI, X-ray.

Coating/Finishing

- Conformal coating, potting, cleaning, ATE enabling technologies.

Logistics and Warehousing

- Well-managed logistics and warehousing to stage components and boards.

Engineering Collaboration

- Joint design, DFM, supplier selection engagement.

Program Management

- Skilled program managers to coordinate planning, scheduling, and information flow.

Ideally the turnkey partner is certified to quality standards like ISO-9001, ISO-13485, AS-9100, or IATF 16949 reflecting process maturity. Review potential partners’ credentials, continuously invested capital, developed talent, proven customer success, quality track record, and continuous improvement thinking.

Best Practices for Implementation

Following best practices helps maximize the benefits of using a turnkey assembly model:

- Select turnkey vendor early for collaborative design input.

- Strategically allocate risks/responsibilities between parties.

- Establish processes for regular communication and visibility.

- Schedule periodic strategy reviews for improvement opportunities.

- Create contingency plans and exit strategies as precautions.

- Implement performance metrics with incentives and regular reporting.

- Maintain internal assembly expertise for monitoring capabilities.

- Phase in turnkey process transfer in manageable stages if possible.

- Qualify vendor across all required assembly technologies through audits.

- Review change management processes for modifying assembly workflows.

- Seek detailed test coverage but also in-house intelligence validation.

- Pursue quality gains through root cause investigation and prevention.

Suitable Product Applications

Some electronics applications that are especially well-suited to a turnkey assembly model include:

- Complex mixed technology boards requiring SMT, thru-hole, press-fit

- High mix products with frequent configuration changes

- Short lifecycle products needing fast ramp up and ramp down

- Commodity type products requiring competitive costing

- Supply constrained components needing allocated supply

- Safety critical assemblies demanding integrated quality control

- Products requiring custom labeling, packaging, or finishing steps

Summary Recommendations

In summary, here are recommendations on capitalizing on turnkey PCB assembly based on specific product scenarios:

Lower Complexity/Volume – Utilize targeted specialty vendors for specific process technologies to maximize expertise and cost competitiveness when overall complexity is low.

Variable Demand – Seek turnkey flexibility to efficiently rebalance staff and equipment across processes as product demand fluctuates.

Fast Ramp – For products needing accelerated production ramp up, turnkey synergy and priority resource allocation speeds time to market.

Maximum Reliability – For ultra-high reliability assemblies, turnkey integration and strict process controls manages overall quality.

Process Innovation – Turnkey provider relationships allow leveraging the latest manufacturing innovations and automation.

Cost Leadership – For high volume cost driven assemblies, turnkey economies of scale, purchasing leverage, and value engineering can achieve cost leadership.

Conclusion

For many complex electronic assemblies, leveraging a full turnkey PCB assembly partner can provide major benefits in quality, speed, and simplified sourcing compared to maintaining multiple contract manufacturing relationships. But product characteristics, volumes, cost targets, quality needs and business considerations determine whether the turnkey tradeoffs are advantageous or not. With mindful implementation and active management, turnkey assembly can produce win-win outcomes for both customer and EMS provider.

Frequently Asked Questions

###Q: What approvals are required to work with a new turnkey assembler?

A: Typical qualifications include site audits, review of test coverage, quality certifications, agreement on metrics/KPIs, customer specified reliability testing, review of change control and configuration management processes, evaluation of business continuity provisions, etc. to validate capabilities.

###Q: Can a turnkey partner manage the entire PCB fabrication process too?

A: Some turnkey EMS providers have in-house PCB fabrication capabilities allowing fully integrated fabrication through assembly. But standalone assembly turnkey is more common.

###Q: How can customers avoid becoming technologically disengaged from turnkey assembly?

A: Maintaining internal assembly and test engineering expertise even with outsourcing provides visibility into process capabilities. Periodic technology reviews and site visits keep skills fresh while monitoring vendor capabilities.

###Q: Are there risks associated with turnkey management of intellectual property?

A: Protecting customer data/IP requires implementing security provisions in outsourcing agreements, restricting data access to core project teams, using secure data transfer practices, and other IT controls.

###Q: How are unique customer quality requirements handled with turnkey assembly?

A: Dedicated workcells, material segregation, subprocess monitoring, serialized tracking, specialized testing, corrective action reporting, and other steps align processes to stringent quality needs at added cost.