Soldering is a process used to join metal components together by melting and applying a filler metal (solder) to form a strong metallic bond between the parts. Choosing the right soldering temperature is crucial for creating secure, long-lasting solder joints. The optimum temperature depends on the metals being soldered, the solder alloy used, and the desired speed and quality of the joint.

Factors that influence ideal soldering temperature

Several key factors impact the ideal soldering temperature:

Type of metals being joined

The type of metal significantly affects the needed soldering temperature. Lead-free solder alloys require higher melting temperatures than traditional tin-lead solders. Common metal types and their recommended soldering temperatures:

| Metal | Soldering Temperature Range |

|---|---|

| Aluminum | 475-550°F (246-288°C) |

| Copper | 700-800°F (371-427°C) |

| Gold | 700-800°F (371-427°C) |

| Nickel | 1000-1300°F (538-704°C) |

| Silver | 500-800°F (260-427°C) |

| Steel | 375-475°F (191-246°C) |

| Brass | 650-850°F (343-454°C) |

Solder alloy

Different solder alloys have different melting points, requiring adjusted soldering heat. Common alloy types include:

- Tin-lead: 361°F (183°C) melting point. Traditional electronics solder.

- Lead-free tin-copper: 500°F (260°C) melting point. For lead-free requirements.

- Lead-free tin-silver-copper: 217-361°F (103-183°C) melting points. Various alloy mixtures.

- Silver solder: 1125-1350°F (560-730°C) melting point. For high-temperature joints.

Matching the solder type to metals is vital.

Joint type and size

The type of solder joint and its size impacts heat needs. Larger joints require higher temperatures to thoroughly heat the joint and molten solder to fill it. Types include:

- Butt joints – common flat surface joints

- Lap joints – overlapping sheet metal joints

- T joints – perpendicular joint between surfaces

- Corner joints – L-shaped angled joints

Bigger, more complex joints need higher soldering heat.

Desired speed

Faster soldering requires higher temperatures to melt solder quickly. But too-hot temperatures can damage electronics. Choosing heat based on speed vs. safety is key.

Desired joint quality

Higher quality solder joints need adequately high heat to form a thorough bond. Temperatures that are too low produce weak, unfinished joints.

Best practice soldering temperatures

While the optimum soldering temperature depends on the application, some general best practice recommendations can guide temperature selection:

Lead solder alloys

600-700°F (315-371°C) is ideal for most tin-lead electronics soldering. This gives a good balance of melting speed without excessive heat exposure.

Lead-free solder alloys

700-800°F (371-427°C) is typically used for lead-free solders to account for their higher melting points.

Large electrical joints

Very large wire joints may require 750-850°F (399-454°C) to sufficiently penetrate the full connection area.

Silver soldering

Silver soldering temperatures range from 1125-1350°F (560-730°C), needing specialized torch heating.

In general, use the lowest temperature that achieves an effective, rapid joint without damage.

Recommended soldering methods by temperature

Matching your soldering method and equipment to the temperature range needed is vital for success. Recommended techniques include:

| Temperature Range | Recommended Soldering Methods |

|---|---|

| Under 500°F (260°C) | Low-wattage soldering iron, soldering station |

| 500-800°F (260-427°C) | Standard 40-60W soldering irons |

| 750-1300°F (399-704°C) | High-power soldering guns, torches |

Signs of incorrect soldering temperature

Using unsuitable soldering temperatures will produce visible signs of flawed joints:

Low Temperature Indications

- Dull, grainy joint finish

- Poor wetting and flow of solder

- Incomplete joint penetration

- Weak, brittle joints

High Temperature Indications

- Burnt flux residues

- Overheated joint metals

- Damage to nearby components

- Excessive solder flow out of joint

Adjusting your temperature appropriately will improve results.

Soldering Tips by Project Type

Tailoring your soldering approach to the specific project provides better outcomes.

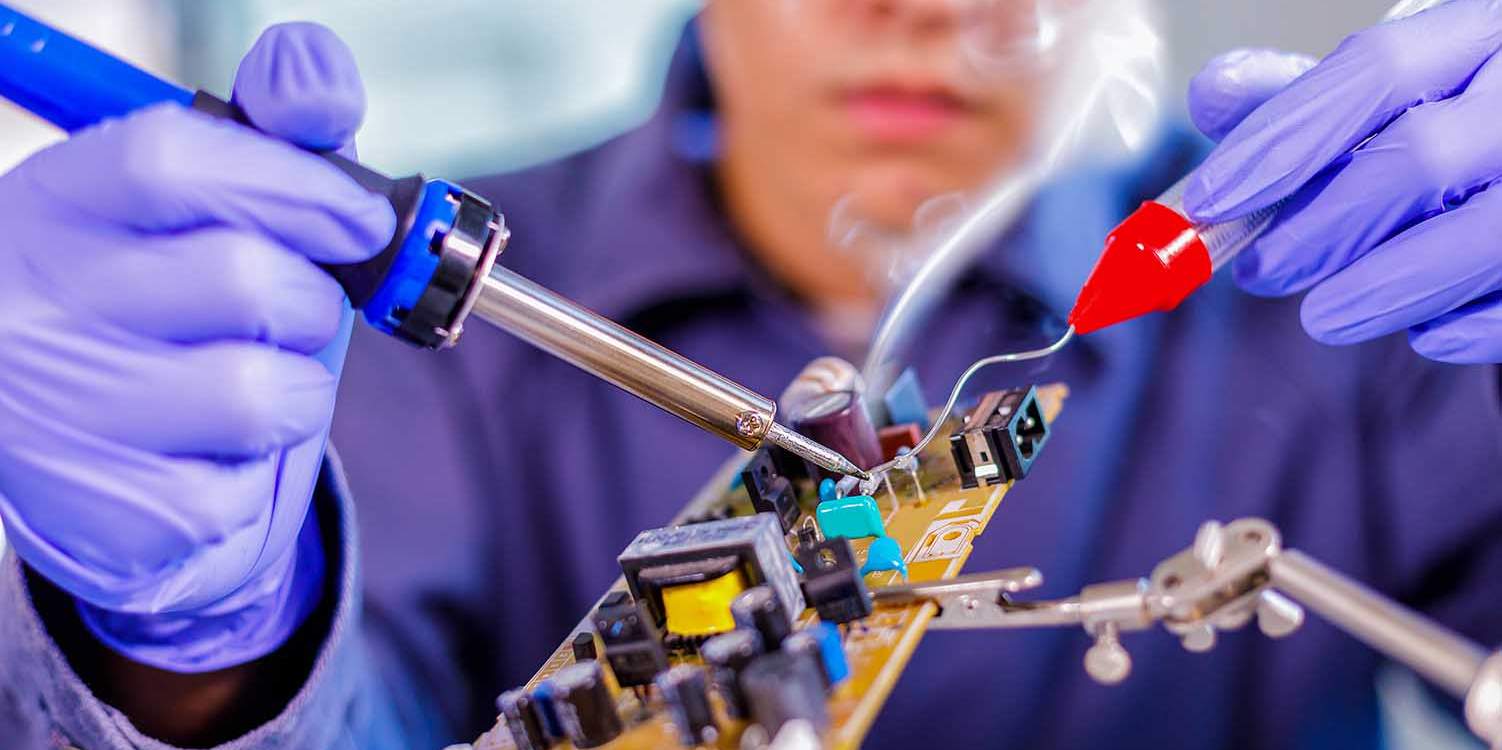

Electronics Soldering

Use 600-700°F (315-371°C) with rosin-core lead solder or 700-800°F (371-427°C) with lead-free cored wire. Apply just enough heat at each joint for 60/40 tin-lead or Sn/Cu/Ag alloys to flow freely.

Sheet Metal Soldering

Attaching metal sheets requires adequate heat like 700-800°F (371-427°C) to penetrate both sheets with molten solder. Use metal filler material matching the metals joined.

Copper Pipe Soldering

Plumbing pipe joints need lead-free tin-antimony or silver-bearing solders, using 500-650°F (260-343°C) for tin-antimony and far higher temperatures for silver alloy brazing. Localized heat application creates leak-free piping.

Stained Glass Soldering

Lead-based and lead-free solders with melting points below 500°F (260°C) allow glass soldering without cracking the glass. Precision temperature control is vital.

Conclusion

In soldering, heat is your friend when applied judiciously but can badly damage materials when excessive. Match your temperature range to your specific metals and project goal for the best results. With the proper joint type, preparation, solder, flux and temperature, you’ll create lasting, trouble-free soldered pieces.

Frequently Asked Questions

Got soldering temperature questions? Here are answers to common queries:

What is the most common soldering temperature?

For electronics work, 600-700°F (315-371°C) when using traditional tin-lead solder, and 700-800°F (371-427°C) when using lead-free solder.

What temperature should I solder copper pipe?

500-650°F (260 – 343°C) is recommended for copper plumbing pipes when using tin-antimony or tin-silver solder alloys.

Is 400°F hot enough to solder?

While 400°F (204°C) may work for some lead and tin-based solders with very low melting points, it is generally too cool for most solders to fully melt and flow correctly.

Can overheating damage electronics when soldering?

Yes, excessively high temperatures can overheat and damage delicate electronic components and materials when soldering. Approx. 700-800°F (371-427°C) is widely recommended for electronics.

What is silver soldering temperature?

Silver soldering requires very high temperatures of around 1125-1350°F (560-730°C) to melt specialized silver-bearing alloys and make joints. It needs torch heating rather than standard irons.