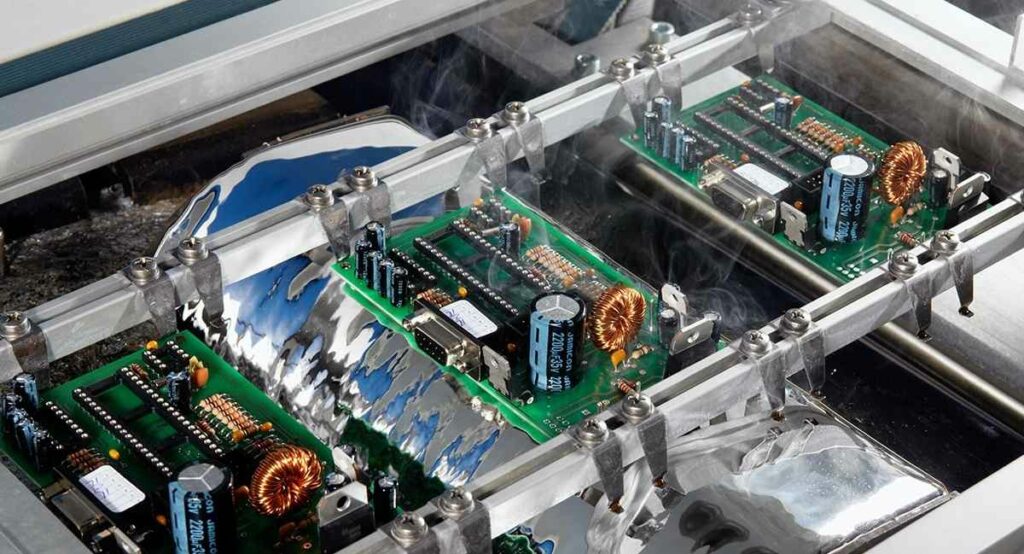

Reflow ovens are an essential piece of equipment for electronics manufacturing using surface mount technology (SMT). They use precise heating profiles to melt solder paste and attach surface mount components like resistors, capacitors, and integrated circuits to printed circuit boards (PCBs).

This article provides an overview of leading reflow oven manufacturers, typical costs based on features and throughput, and the key temperature parameters that characterize a reflow profile. With this information, electronics manufacturers can make an informed decision when selecting a reflow oven that meets their production needs.

Reflow Oven Manufacturers

There are several major global manufacturers of reflow ovens serving the electronics assembly industry:

Ersas

Ersas, part of the Kurtz Ersa group based in Germany, offers convection and vapor phase reflow ovens under its ERSAS Rework and ERSAS Production lines. Its high-end convection ovens feature innovations like smart nitrogen control to reduce solder defects.

Heller

Part of GM Nameplate, Heller Industries manufactures convection and vapor phase ovens in the United States. Its 1911 MK5 series offers an 11-zone conveyorized tunnel oven configurable for different profiles. The PowerHeat series focuses on high thermals and quick ramps.

Electrovert

With its headquarters in Ireland, Electrovert (part ofstow Automation) produces Eria brand reflow ovens. The Eria Voyager convection ovens come in standard and high performance variants with features like vacuum transport. The Eria Mistral is an economy range air or nitrogen oven.

Rehm Thermal Systems

German manufacturer Rehm offers convection, condensation, and vapor phase ovens for both lead-free and semiconductor packaging applications. Its Vision XP+ line offers high-end convection ovens with innovations like the VacuMotion transport system to eliminate pins.

Vitronics Soltec

Vitronics Soltec, headquartered in Germany, produces the Centurion and XPM2 convection reflow oven series. Both lines offer high thermal performance for lead-free profiles. The XPM2 also comes in larger versions to handle boards up to 850 x 1,050mm.

Reflow Oven Pricing

Reflow oven prices cover a wide range based on the features, configuration options, and production throughput selected:

Economy: $15,000 to $30,000

- Simple small footprint convection ovens

- Manual load/unload

- Limited profiling/traceability

Mid-range: $30,000 to $60,000

- Larger ovens with conveyor transport

- Enhanced profiling and temperature control

- Nitrogen atmosphere options

- SME/mid-volume production

High-end: $60,000 to $250,000+

- High throughput, large board capability

- Vacuum transport, pinless handling

- Smart multi-zone convection

- High flexibility, traceability

- High mix/large volume production

In general, manufacturers size and price reflow ovens based on the board size, peak temperature capability, and hourly throughput or boards per hour (BPH). Adding advanced features like profiling software, convection modules, or transport systems increases costs.

Reflow Profiles

The core purpose of a reflow oven is to produce thermal profiles that properly melt solder paste and form high-quality solder joints without damaging sensitive components. While each combination of PCB design, components, and solder alloy requires custom profiling, some common characteristics define a typical reflow profile:

Stages

Reflow profiles consist of four main thermal stages:

- Preheat: A ramp-up period that gradually heats the assembly from around 150-200??C. It activates flux and helps reduce thermal stress.

- Soak: A brief dwelling period around 150-200??C to equalize temperatures across the board.

- Reflow: The rapid ramp up above 200??C when solder melts and wets pads. The peak temperature depends on the solder alloy used. Common profiles reach 230-260??C.

- Cool down: A controlled cooldown to solidify solder joints while minimizing thermal stress. Cooling should not exceed 4??C/second.

Peak Temperature

The maximum profile temperature depends on the solder alloy:

- Tin-lead alloys can peak around 215??C

- Lead-free alloys require higher peaks of 230-260??C

Exceeding peak temperatures risks component damage while lower peaks can produce poor wetting and cold solder joints.

Thermal Performance

Key oven specifications that indicate profiling performance include:

- Heating/cooling rate capabilities

- Range of settable peak temperatures

- Soak zone configurations

- Number of individually controlled heating zones

More zones, tighter control over ramps, and higher peak temperatures allow more refinement of custom profiles.

Atmosphere

Many reflow ovens support switching between air and nitrogen atmospheres:

- Air reflow is simpler and more economical. It requires good ventilation measures.

- Nitrogen helps prevent oxidation and minimizes some defects, producing better solder joint cosmetics and wetting.

Reflow Oven Features Comparison

| Model | Transport | Atmosphere | Max Temp | Board Size | Profile Points | Starts at |

|---|---|---|---|---|---|---|

| Ersas Multifusion | Dual conveyor | Air/N2 | 260??C | 510 x 508mm | 10 per zone | $120k |

| Heller 1911 MK5 | Pin chain conveyor | Air/N2 | 290??C | 457 x 610mm | 12 zones | $175k |

| Electrovert Eria Voyager | Vacuum transport | Air/N2 | 260??C | 610 x 635mm | 25 | $250k |

| Rehm Vision XM | VacuMotion | N2 | 330??C | 510 x 635mm | 5 per zone | $150k |

| Vitronics XPM2 | Chain conveyor | Air | 260??C | 850 x 1050mm | 5 stages | $85k |

Reflow Soldering Defects

Two common solder joint defects related to the reflow process include:

Cold Solder Joints

Poor wetting that leaves dull, convex joints with weak adhesion to pads. Caused by insufficient heating during reflow.

Solder Balling

Small globs of solder that end up stuck to assemblies after reflow. Often traced back to issues with solder paste printing.

Careful profiling helps avoid these and other thermal process defects.

Frequently Asked Questions

What is the difference between a convection and a vapor phase oven?

Convection ovens use heating elements and fans to circulate hot air and create reflow profiles. This gives great heat transfer efficiency and flexibility in custom profiling.

Vapor phase ovens immerse assemblies in an inert liquid like fluorinert that boils at a fixed temperature to reflow solder. The boiling action provides gentle, uniform heating. However, they offer less profiling flexibility compared to convection.

What features help make manual board loading/unloading easier?

Most reflow ovens above entry-level have automated transport like conveyors or rail guides. For manual operation:

- Wide pass-through doors simplify inserting and retrieving assemblies

- Product detectors help prevent mishandling hot boards

- Ergonomic workflows with suitable working heights reduce strain

Should I choose air or nitrogen reflow?

Here are some factors when selecting an atmosphere:

- Nitrogen helps reduce oxidation defects and can improve wetting on tricky alloys. It costs more to implement though.

- Air reflow is a good economical option if you have air handling infrastructure and aren’t seeing atmosphere related defects.

- Switchable atmospheres offer flexibility if your needs change in the future.

What real-time data should I monitor in the reflow oven?

Critical process parameters to monitor include:

- Heating zone temperatures

- Total thermal loads

- Conveyor speed / dwell time tracking

- Atmosphere oxygen level (for nitrogen ovens)

- Cooling temperature differentials

This data ensures parameters stay within acceptable process windows regardless of line conditions.

How often should reflow ovens gets serviced?

An annual preventative maintenance check from the manufacturer helps keep the oven performing reliably:

- Inspect key components like fans, heating elements, and atmosphere sensors

- Confirm thermal uniformity across zones

- Check chain/transport mechanisms for wear

- Backup/update software and calibration firmware

Conclusion

With surface mount assembly dominating modern electronics, a high performance reflow oven matched to production needs is a vital investment. This overview of popular manufacturers like Ersas and Heller, typical pricing ranges, key features impacting profiling, and common defects provides electronics manufacturers guidance in selecting the right soldering oven. Matching the oven capabilities to board size, mix complexity, solder alloy, and quality requirements ensures trouble-free reflow soldering.

Reflow Oven Buying Checklist

- Production volume (boards per hour)

- Board sizes supported

- Handling – conveyor, rail, robotic

- Heating – zones, rates, uniformity

- Atmosphere – air, nitrogen

- Temperature range and profiling

- Software – traceability, datalogging

- Budget – balance cost vs capabilities