It’s very common to see green colored printed circuit boards (PCBs) in all types of electronic products these days. However, occasionally one may come across circuit boards with a bright red hue instead. This often leads people to wonder what reasons explain the use of red colored PCB substrates.

In some cases, the red color serves only decorative purposes to match product branding or differentiate board types visually. However, more technically, choosing red laminates stems from specific functional performance advantages the color imparts related to the board material composition.

By understanding what makes a PCB red plus the associated benefits and tradeoffs compared to traditional green substrates, one can determine when specifying red PCBs proves advantageous.

Origins of Red PCB Color

To understand what makes some circuit boards red, we must trace back to the core layered construction that forms their foundation. All PCBs consist of an insulating laminate base material reinforced with woven fiberglass that strengthens and stabilizes the structure.

Standard glass fabric reinforced epoxy laminates appear green simply due to the natural color of the woven mesh embedded within. The greenish translucent hue arises just from the intrinsic coloration of traditional fiberglass materials.

However, an alternative exists…

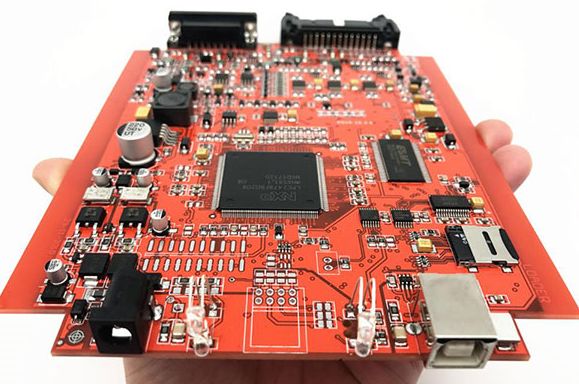

Ceramic Filled PTFE Composites – By substituting woven fiberglass with a woven fluoropolymer (PTFE) mesh reinforced with ceramic particles, the resulting laminate exhibits an opaque reddish appearance completely different from conventional green boards.

So the source of red PCB color stems specifically from the unique material formulation replacing standard glass fabric with ceramic loaded PTFE reinforcement fillers. This modification in materials also imparts enhanced electrical, thermal and mechanical characteristics that we will explore next.

Key Characteristics of Red PCB Materials

Red PCB laminates contrast the norm primarily across three property aspects:

1. Electrical Performance

Table: Properties of Red PCB Laminates

| Parameter | Red PCB | Standard PCB |

|---|---|---|

| Dielectric Constant | 3.0 | 4.5 |

| Loss Tangent | 0.002 | 0.02 |

| Breakdown Voltage | 6 kV/mm | 1.5 kV/mm |

2. Thermal Management

- Excellent thermal conductivity for heat spreading

- Low coefficient of thermal expansion for stability through temperature excursions

- High continuous use temperature rating above 270°C

3. Structural Rigidity

- Extremely strong and rigid at thin cross sections

- Dimensional stability through humidity and mechanical stress exposure

- Ideal for thin cores in multilayer boards above 14 layers

Clearly, red PCB materials deliver substantial performance gains electrically, thermally and mechanically – but at what tradeoff cost?

Tradeoffs When Using Red PCB Materials

While red PCB laminates excel technically on multiple fronts, they do come with some downsides makers should consider before specifying:

Cost – High performance fluoropolymer composites run 5-15X more expensive than conventional FR-4 glass epoxy boards due to raw material and processing differences.

Lead Times – More specialized manufacture and limited industry adoption of red PCBs extends delivery schedules typically 4 to 6 weeks longer than standard PCBs. Plan accordingly.

Rigidity – The extreme stiffness that aids precision comes at the expense of flexibility, hampering use in dynamic bending applications. Standard PCBs better tolerate moderate flexing.

Repairability – The ceramic fill and PTFE matrix forming red boards proves extremely difficult to drill or desolder once cured, hampering component replacements.

So while gains exist in electrical and thermal parameters enabling cutting edge miniaturization and density, one must weigh the downsides of inflated costs, extended procurement timelines and diminished serviceability. Understanding these tradeoffs now allows intelligently specifying right material choices per application.

Applications Benefitting from Red PCB Materials

We now understand the nuances of when reaching for red colored PCB materials makes sense. Here are some common situations where the positives outweigh the limitations:

High Frequency Circuits – When RF or microwave circuitry calls for ultra low loss tangent laminates to prevent signal attenuation or dielectric absorption distortion, the superior electrical purity of red boards shines.

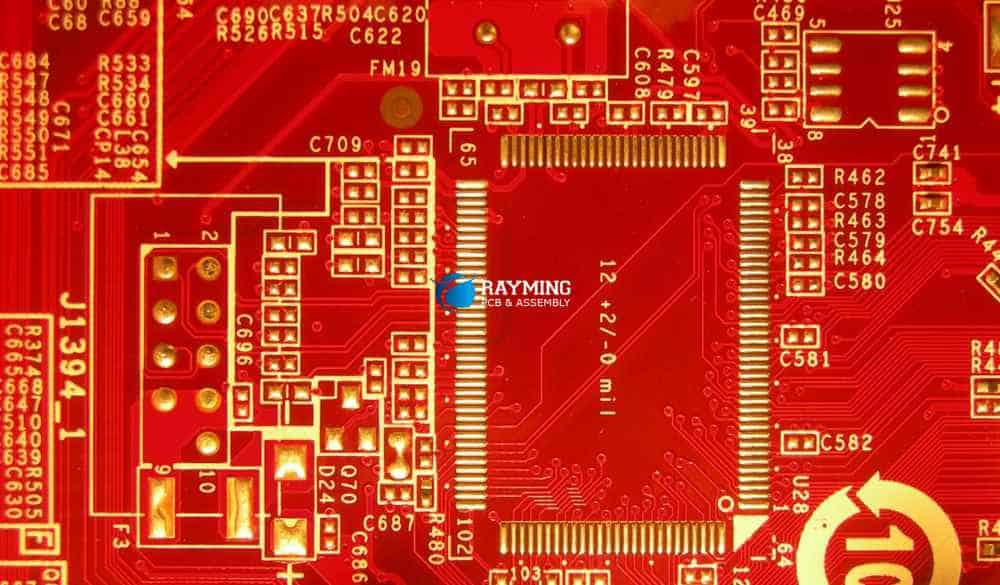

High Density Interconnects – Space savings from shrinking trace geometries and clearances while still meeting isolation needs relies on the enhanced dielectric properties and breakdown voltages red laminates provide.

High Power Devices – Efficient heat dissipation for volt hungry power semiconductors using red PCBs with extreme thermal conduction prevents hot spots that would throttle performance or hasten failures otherwise.

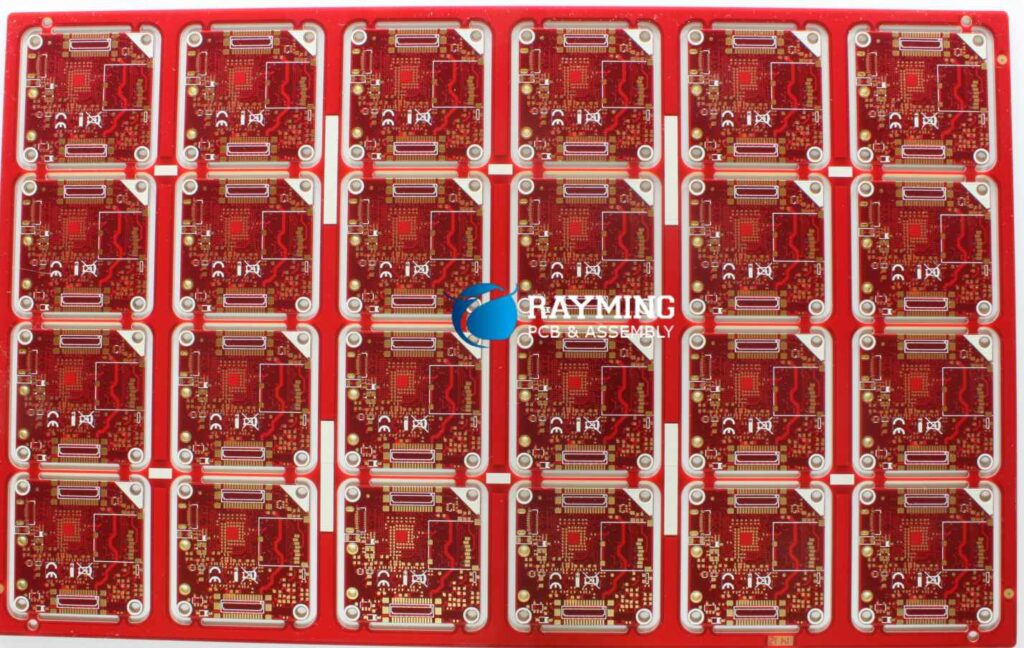

High Layer Count Circuits– Mission critical computing systems demand stacking 20+ PCB layers connected via blind vias. The rigidity and dimensional accuracy of red materials prevents registration issues or fracturing vulnerable plated through holes across long, repeated thermal excursions.

So for such complex, compact and load intensive applications where standard green PCB properties hit limitations, upgraded red circuit boards deliver the enhanced electrical, thermal and mechanical reinforcement needed for next generation product roadmaps.

Example Red PCB Substrate Offerings

Many leading global PCB manufacturers now offer red board material technology in their capabilities portfolio. Some common industry product codes for these high performance red laminates include:

Rogers RO4003C / RO4350B – Ceramic filled woven PTFE composites with extremely low loss – Popular from RF/microwave specialist Rogers Corp with tier 1 longevity

Taconic TACONIC TRF – Family equivalent to Rogers offering similar electrical metrics

Isola IS420 – Next generation low Dk, low Df laminate purpose built for high speed computing applications

Ventec VT-901 – High reliability red substrate for rugged aerospace and defense products

So whether optimizing impedance tolerances for a 28+ GHz mmWave antenna array or a blade server CPU mounting requiring immaculate thermal transfer through a 22 layer interface, quality assured red PCB substrates deliver advanced solutions.

Conclusion

In summary, while most PCBs appearing green stems simply from standard fiberglass reinforcement hues, non-traditional exotic red laminates replace glass with ceramic loaded fluoropolymer matrices that enhance electrical, thermal and mechanical attributes to raise performance.

Understanding the pros/cons of red boards allows appropriately specifying them only where their cost and manufacturing differences pay off enabling cutting edge technical capabilities maximizing circuit density, signal quality, power efficiency and reliability under challenging operating conditions.

Frequently Asked Questions

Q: Can components be mounted on both sides of red PCBs?

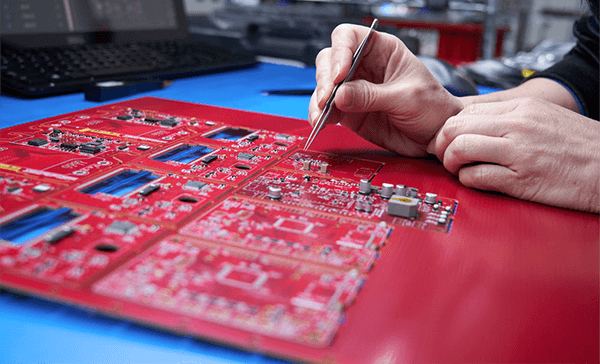

A: Definitely – red boards support equivalent double sided SMT assembly just like conventional PCBs. The unique laminate construction and color only alters internal layers while preserving identical outer surfaces for populating parts across the full area as needed by circuit complexity.

Q: Do red PCBs require special CAD tools or layout rules?

A: Generally red substrates work seamlessly with existing PCB software suites for layout by just substituting the material stackup properties and layer thicknesses accordingly. Constraints mirror traditional designs aside from thermal relief considerations.

Q: How do red PCB costs compare to more exotic substrate options?

A: Surprisingly red laminates compete very closely in price with popular PTFE composites like Rogers 4000 series circuits while delivering superior thermal conductivity and rigidity. Only ceramics cost vastly more as niche space qualified solutions.

Q: Can traditional leaded or RoHS components be used on red PCBs?

A: Absolutely – red boards offer full compatibility with all passive and active through-hole or SMT device packages. Only limitation rests with soldering process windows matching their higher melting fluoropolymer resin systems during component attach.

Q: Will red PCB usage grow further across consumer electronics?

A: Unlikely due to overkill performance and price points. Red laminates mainly serve advanced commercial/industrial applications today. But some prestige flagship consumer devices may adopt red PCBs for select subsystems like wireless modems to claim best-in-class RF merit.