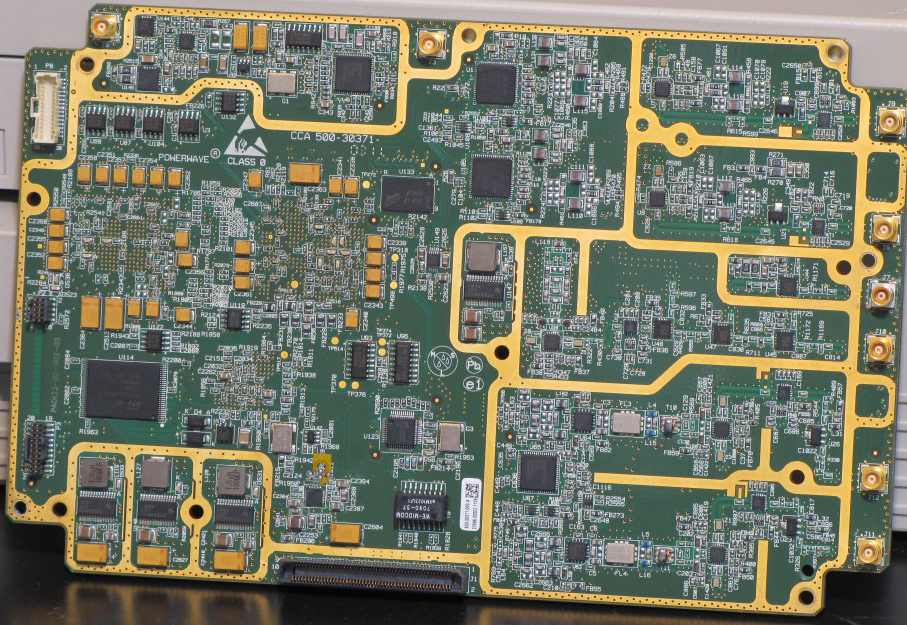

Developing new electronic products requires testing out multiple printed circuit board (PCB) design iterations during the R&D phase. Rapid PCB prototyping allows engineers to quickly obtain boards in small batches to validate their evolving concepts without long lead times or minimum order requirements. This guide examines available online services for fast prototype PCB fabrication and how to leverage them effectively.

What is Rapid PCB Prototyping?

Rapid prototyping refers to the ability to manufacture a functional PCB prototype on-demand in just a few days, rather than waiting weeks or more for a production board order. It is especially useful during early development when the design is still fluid and engineers need boards quickly to test form, fit, and function.

Key characteristics of rapid prototyping services include:

- Lead times from 24-72 hours

- Low minimum order quantities (1-5 boards)

- Low per-board NRE costs

- Limited DFM checks and approvals

- First pass success may be lower

- Focus is on speed, not optimizing yield

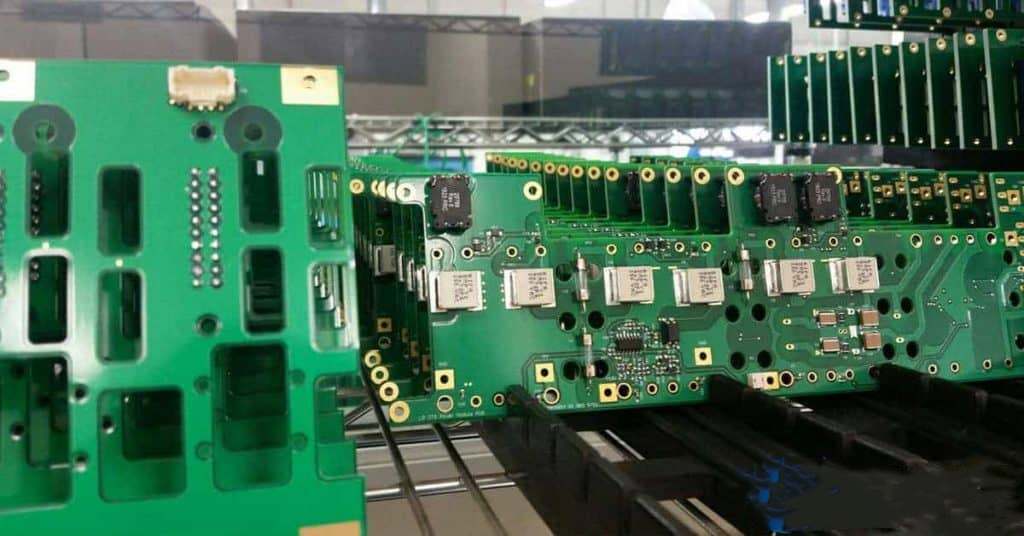

Rapid prototyping sacrifices some manufacturing discipline to enable fast turnaround and hands-on PCB testing. Let’s examine popular options for accessing quick-turn boards online.

Online PCB Prototyping Services

Several PCB manufacturers now provide online services for effortless 24-48 hour board prototyping:

PCBWay

- 24 hour expedited service

- Starts at 10 boards from $5 per board

- SMT assembly optional

- Fr4, Aluminum, Rogers, Flex, etc.

- Free DFM check

JLPCB

- 24 hours express possible

- 5 boards from $2 each

- LITHO technology

- FR4, Rogers, Flexible

- Lower cost location

WellPCB

- 3 day rapid service

- 1 board from $99 flat fee

- Design review included

- FR4, Rogers, HDI, Rigid-Flex

- US based facility

MacroFab

- 36 hour turn time

- Low minimums from $33

- Design for manufacturing analysis

- Assembly and stencil options

- 24/7 customer access

These services make getting started with fabricated boards much quicker through online accessibility and streamlined logistics direct from the manufacturer.

Benefits of Online Prototyping

Sourcing PCB prototypes online provides several advantages versus traditional local board shops:

No Minimums

Online services offer single piece orders and tiny minimum quantities starting at just 1 or 2 boards. Local shops often require 50-100+ quantity minimums.

Lower Cost

Direct order fabrication cuts out dealer margins for reduced cost, with prices as low as $2-5 per square inch. Local shops markup prototypes much higher.

Faster Lead Times

Orders placed online can be manufactured in 1-2 days versus 1-2 weeks for most local PCB suppliers.

Design Analysis

The best online services offer free DFM checks to optimize the design for manufacturability before your order. Local shops often provide zero design feedback.

Flexible Options

Online services support a range of materials beyond just FR-4 boards including flex, HDI, aluminum, Rogers, etc. Local shops have limited capabilities.

Order Tracking

Watch your order progress in real-time online through manufacturing and shipping. Little visibility is provided by local suppliers.

Convenient

Orders can be placed 24/7 in minutes from anywhere rather than coordinating locally during business hours.

For quickly obtaining inexpensive prototypes during R&D and new product introduction, online sourcing provides unparalleled convenience and accessibility to meet tight development schedules.

How Online PCB Prototyping Works

Ordering PCB prototypes online follows a streamlined process:

1. Upload Design Files

Upload your Gerber, drill, and other fabrication files to the service’s site. Ensure you include any special instructions.

2. Design Review (Optional)

Some services provide a free design for manufacturability (DFM) check to catch any potential issues before production.

3. Enter Order Details

Select board specs like material, layer count, finish, and enter quantities to get an instant quote.

4. Submit Order and Payment

Place order online by submitting payment details for secured checkout. Credit cards or Paypal are accepted.

5. Manufacturing and Status Updates

Watch your order status on the website as it proceeds through prototyping, testing, and final shipping.

6. Receive Prototypes

Boards arrive quickly in just 1-3 days via global express shipping right to your door.

It’s an easy streamlined way to get boards in hand ultra-fast for product development compared to traditional suppliers.

What Capabilities are Available?

Rapid PCB prototyping services support a diverse range of board technologies:

- FR-4 Boards – Standard glass epoxy material

- Rogers and High Frequency – Many offer RF materials like Rogers 4003

- HDI Boards – For high density interconnect needs

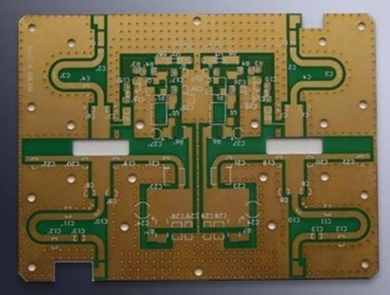

- Rigid-Flex – Combining rigid and flex circuits

- Aluminum Boards – For thermal dissipation

- Multi-Layer – Stackups up to 12+ layers

- Impedance Control – For matched transmission lines

- Heavy Copper – For high current applications

- Flex PCBs – Bendable flexible circuits

- Advanced Finishes – HASL, ENIG, Immersion Silver, OSP

This range covers most needs for functional prototypes through proof of concept and product development testing before committing to full production runs.

Prototyping vs Production

While expedited services enable fast prototyping, engineers should be aware of key differences from full production:

- Reduced Testing – Lower test coverage and inspection versus production

- Lower Yields – More prototypes fail electrical or quality checks

- Limited DFM – Upfront design reviews may be minimal or optional

- Reduced Reliability – Potentially fewer lamination layers or plated copper

- Limited Scalability – Not intended for high volume manufacturing

- No Guarantees – Prototypes have no warranty and are “as-is”

The goal is fast fabrication to get boards in hand quickly during development, not optimized manufacturing quality like production. Expect to go through several prototype design spins before finalizing the design for production.

When to Use Rapid Prototyping Services

Rapid PCB prototyping services are ideal during these product development phases:

- Concept Validation – Testing form, fit, and function quickly during R&D

- Design Verification – Validating schematics and layout before full commit

- Design Iteration – Trying multiple variations to refine the concept

- Early Software Development – Testing firmware and drivers on actual boards

- Documentation Support – Populated boards for user manuals and guides

- Marketing Samples – Demonstration units, comps, and mockups

Rapid prototyping supports the highly iterative development process before the design is proven and ready for mass production.

Transitioning to Production

Once the design is finalized, engineers should take key steps before volume manufacturing:

- Design Review – Have your vendor do an in-depth DFM analysis to catch any issues early. Review the full assembly process.

- Pre-Production Samples – Test out at least a small pilot run with standard testing to validate manufacturing processes before committing to thousands of boards.

- Qualification Testing – Put prototypes through environmental stresses like temperature cycling and vibration to uncover potential field failures.

- Test Coverage – Expand electrical testing like in-circuit test (ICT) and flying probe to catch any assembly flaws.

- Process Documentation – Work with your CM to document approved fabrication and assembly procedures needed for product release.

Your contract manufacturer will guide you through manufacturing handoff to ensure a smooth ramp to scalable, reliable production.

Getting Online Prototype PCB Assemblies

In addition to bare PCBs, some online services offer assembled boards with components soldered:

- Upload complete BOM and centroid file for SMT placement

- Quick-turn SMT assembly in parallel with PCB fabrication

- Machine-placed components, not hand assembled

- Limited to easier components for prototyping

- Single-sided board designs ideal for assembling

- Functional testing for power on validation

- Low minimums, e.g. 5 pcs assembled

- Upload any specialized test procedures

Assembled prototypes allow comprehensive system testing before high volume manufacturing.

FQA About Rapid PCB Prototyping Services

How quickly can I receive PCB prototypes online?

The fastest services offer 24 hour fabrication with global express shipping for boards in just 1-3 days.

What design files do I need to submit?

Gerber files, drill file, netlist or BOM, assembly drawings, and any special instructions should be uploaded.

What are the limitations of rapid prototyping?

Prototypes involve minimal design review and testing. Yields and reliability are lower than production boards.

Can components be assembled onto rapid prototypes?

Some providers offer quick-turn SMT assembly so prototypes arrive fully populated for testing.

How many rapid prototype iterations are typical?

3-5 iterations is common during development before the design is stable enough for production.

Conclusion

Online rapid PCB prototyping services enable engineers to get functional boards in just days with no minimum order requirements. By facilitating quick design testing and validation, they accelerate product development schedules. Prototyping and small batch services help companies quickly and affordably test concepts before investing in production tooling and high volume fabrication. With access to advanced board technologies and SMT assembly, online prototyping removes barriers to bringing new products rapidly to market.