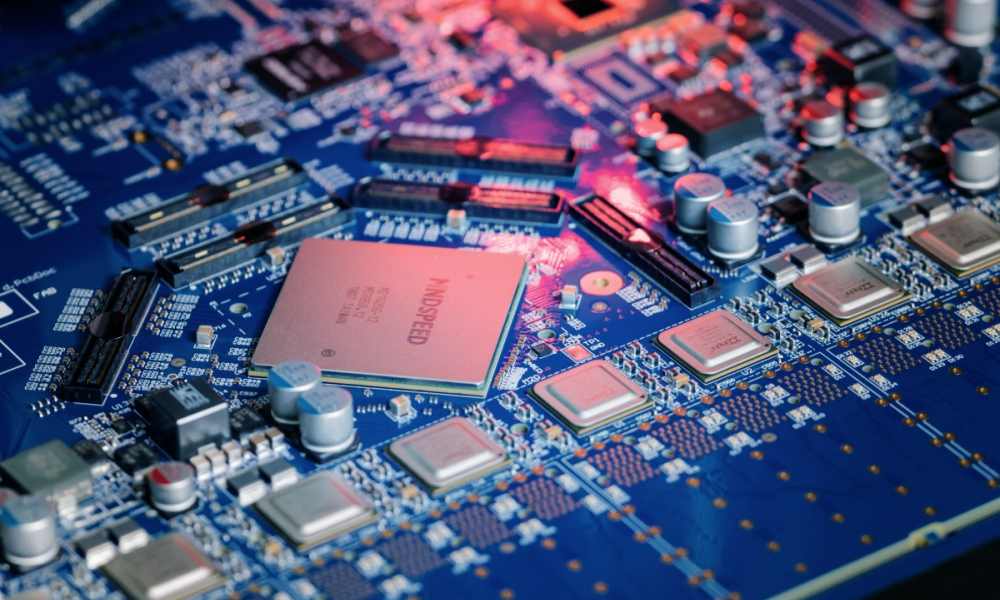

California has one of the highest concentrations of electronic product companies in the world. Many global tech leaders like Apple, Intel, and HP were founded in California and continue to shape the consumer electronics landscape with cutting edge technologies. This creates massive local demand for PCB assembly partners able to translate prototypes into high quality, volume production.

In this guide, we analyze the top 6 PCB assembly manufacturers in California based on key criteria:

1. Rayming Technology

Rayming Technology stands out as a top full-turnkey electronics manufacturing provider spanning PCB fabrication, SMT assembly, component procurement, new product introduction, quality testing, and order fulfillment/logistics based out of Sunnyvale, CA in the heart of Silicon Valley.

Core Competencies

- High mix, medium volume production – 10,000+ active SKUs

- Quick-turn SMT, thru-hole, box-build assembly

- 01005 passive to 0.3mm pitch BGA parts

- Functional test, flying probe, boundary scan

- Inventory management and custom packaging

Rayming leverages massive economies of scale as part of the $3B+ RayMing Group to deliver aggressive pricing while retaining responsive California-based engineering support nurturing startups and smaller customers lacking internal expertise. Especially valuable NPI guidance speeds customers escaping design-for-manufacturing blind spots.

Industry Focus

Covering diverse markets from industrial automation, LED lighting, consumer wearables, building infrastructure, transportation, medical and Internet-of-Things applications – Rayming produces PCB volumes spanning 10 to 10,000+ monthly quantities with localized California assembly.

Notable Customers

Supported customers ship award-winning products across technology segments:

- Tuya (smart home)

- V syntec (laser lighting)

- Swytch (eBike kit)

- Bryton (GPS cycling computer)

- CareOS (oral health tracking)

Location: 331 Huff Ave #C, Sunnyvale, CA 94085, USA

With robust quality certifications like ISO-9001 and flexible production control choices – Rayming gives customers peace of mind during both prototyping and scaling for California centered, US focused or globally distributed products.

2. brows PCB Assembly

brows specializes in creative, small-batch manufacturing with artisan craftsmanship levels from their boutique Bay Area workshop focused exclusively on prototyping innovations.

Core Competencies

- Low volume prototyping &customization – up to 500 units

- PCB, cables, sheet metal, plastics, specialty materials

- Manual to selective automation approaches

- Design experience optimizing manufacturability

- Fast DFM feedback within 1 biz day

Industry Focus

brows customers span startups and inventors across robotics, mobility, music, biotech, consumer, IoT sectors who need help crossing technology valleys of death launching differentiated products.

Location: 860 Malcolm Rd Suite 100, Burlingame, CA 94010, USA

Notable Projects

- Hip-Ipod boombox mashup

- BLE wireless MIDI controller

- CNC desktop vinyl cutter

- Educational walking robots

For entrepreneurs with novel concepts lacking mass production refinement, brows offers close California based guidance transforming ideas into functioning made-to-order prototypes ready for customer testing and validation economically in low volumes.

3. Electronic Manufacturers Inc

A staple across Bay Area engineer benches for over 50 years, Electronic Manufacturers (EMI) continues delivering fast, high mix PCB assemblies trusted by discerning local technologists based on precision American craftsmanship.

Core Competencies

- Quick turn assembly services in 3-5 days

- Wide component selection from connectors to BGAs

- Functional testing and bearing boards

- Design experience provides DFM inputs

Industry Focus

EMI supports Bay Area innovators across horizontal markets like industrial, transportation, IoT, biotech, and instrumentation.

Location: 1850 Homestead Ave, Santa Clara, CA 95050, USA

Notable Customers

Supplying well-known ecosystem neighbors:

- Cisco systems

- Keysight Technologies

- Glassdoor

- TiVo

- Spectrum Medical

With seasoned expertise nurturing Silicon Valley technology upstarts for over 50 years locally, EMI delivers attentive responsiveness rapidly assembling prototypes into working pre-production builds ready for pilot deployments using tailored automation approaches as volumes scale.

4. Bitwise Electronics

Bitwise Electronics bursts onto the scene as an emerging full-stack contract manufacturer equipped with latest Industrie 4.0 connected data systems to disrupt electronics production based from Fresno, CA.

Core Competencies

- Automated optical inspection

- IPC Class 2 & 3 certified

- Testing/validation services

- Secure IT infrastructure protections

- Paperless all-digital workflows

Industry Focus

While open across all electronics categories, Bitwise brings cutting edge solutions towards growing IoT device surge needing connectivity, security and quality with transparent supply chain visibility from California based teams.

Location: 750 Rexton Dr Suite 130, Fresno, CA 93720, USA

Notable Projects

Still actively building openly publicized customer portfolio as part of regional ecosystem development efforts strengthening local advanced manufacturing:

- Early electric aviation startups

- Agtech sensor systems

- Automated inventory replenishment

Bitwise intentions to elevate Central California alongside traditional coastal hubs promises bringing sophisticated smart factory solutions inland with IT system advantages benefitting connected device builders seeking Industry 4.0 leapfrog improvements.

5. Spectra Technologies

Pioneering electronics manufacturing scaling concepts in the 1970s before outsourcing trends, Spectra Technologies sustains delivering complex, quick-turn assemblies from Silicon Valley for nearly 50 years leveraging optimized American automation.

Core Competencies

- Complex mid-volume assembly

- High precision and multidisciplinary

- Quality testing and inspection

- Lean, nimble processes

Industry Focus

Specialized expertise across:

- Medical devices

- Industrial controls

- Semiconductor equipment

- Defense electronics

Location: Santa Clara, CA, USA

Notable Achievements

- First totally automated chip shooter (1987)

- Technical Emmy award for contributions advancing TV manufacturing ecosystems

With such longstanding product realization leadership spanning early Silicon Valley’s prime, Spectra amassed interdisciplinary expertise crafting mid-volume assemblies with intricate precision meeting short lead times – exemplifying viable high-mix electronics production retaining domestic California agility.

6. Creation Technologies

Headquartered just across the Nevada border, Creation Technologies expanded over 30 global sites remains rooted engineering Californian customer partnerships benefitting from relative geographic advantages central within western technology orbits.

Core Competencies

- High mix, medium volume

- Complete product life cycle management

- Value-engineering optimization

- Global manufacturing foot print

Industry Focus

Creation supports nearly every electronics vertical market leveraging wide expertise:

- Industrial

- Transportation

- Communications infrastructure

- Medical

- Defense

Location: USA Headquarters – Burney, CA

Notable Customers

Supplying multinational leaders:

- Emerson

- Honeywell

- Northrop

- General Dynamics

- Olympus

Creation Technologies positioned so close to California OEMs fortifies responsiveness through agile west coast teams scaling globally dispersed production faster hedging regional risks.

Notable California Contract Manufacturers

While dozens of capable contract manufacturers serve California electronic product developers, these highlighted companies capture broad technology ecosystems cutting across common essential competencies like technical responsiveness, quality, controlled processes and volume scalability that ambitious product companies rely on to fuel growth. Partnering the right choice empowers fulfilling innovation commercialization goals ahead.

Now let’s address frequently asked questions about PCB assembly in California.

Frequently Asked Questions

Does localized California production cost substantially more than Asia alternatives?

Misconceptions persist that domestic California production cannot compete on electronics manufacturing costs against foreign regions. However automated smart factory innovations enable California factories achieving near cost parity thanks to logistics, reliability and IP security advantages saving hidden overheads cancelling wage gaps to within ~25% cost premiums.

Why not just rely on large global EMS companies instead of California partners?

Leading global electronics manufacturing services (EMS) firms undoubtedly produce superb quality at high scales. However California startups often struggle navigating their rigid factory hierarchies shoehorning into rigid commodity workflows. Nimble regional shops alleviate friction through better aligned motivations and incentives understanding early stage engineering driven customers distinctly. They embrace the art of small volume manufacturing still with excellence.

Which industry segments are best suited for California based electronics assembly?

Synergies exist across highly fast-moving markets like tech startups for consumer mobile/IoT electronics, cutting edge industrial robots/machinery upgrades and medical devices where close Los Angeles to San Francisco corridor collaboration proximity accelerates innovation commercialization leveraging interdisciplinary expertise density unique to Silicon Valley nourishing the worldwide entrepreneurial edge culture still today.

Why should quality expectations differ between California PCB assembly vs Asia?

While historically perceived tradeoffs positioned domestic quality above overseas manufacturers, modern smart automation helps foreign factories achieve nearly equivalent test coverage and process capabilities on par with premier California builders thanks continuous improvements measuring against universal ISO and IPC benchmarks – closing gaps which previously justified large cost premiums unable detect without data transparency.

What new PCB assembly technologies likely emerge across California long term?

As Silicon Valley pioneers disruptive platforms historically cementing electronics innovation leadership, promising cutting edge contract manufacturing equipment technologies like additive manufacturing, digital twin simulation, advanced robotics, augmented reality, sustainable chemistry/printing processes and artificial intelligence analytics seem poised proliferating initial beachhead adoption clusters soon across California manufacturers pushing envelopes accelerating worldwide exponential technology.

This covers insider perspectives across essential questions weighing ideal California electronics assembly partnerships securing product success. Reach out directly exploring the newest advanced contract manufacturing capabilities rising nearby ready deploying locally today.