Introduction to Quick Turn PCB Assembly

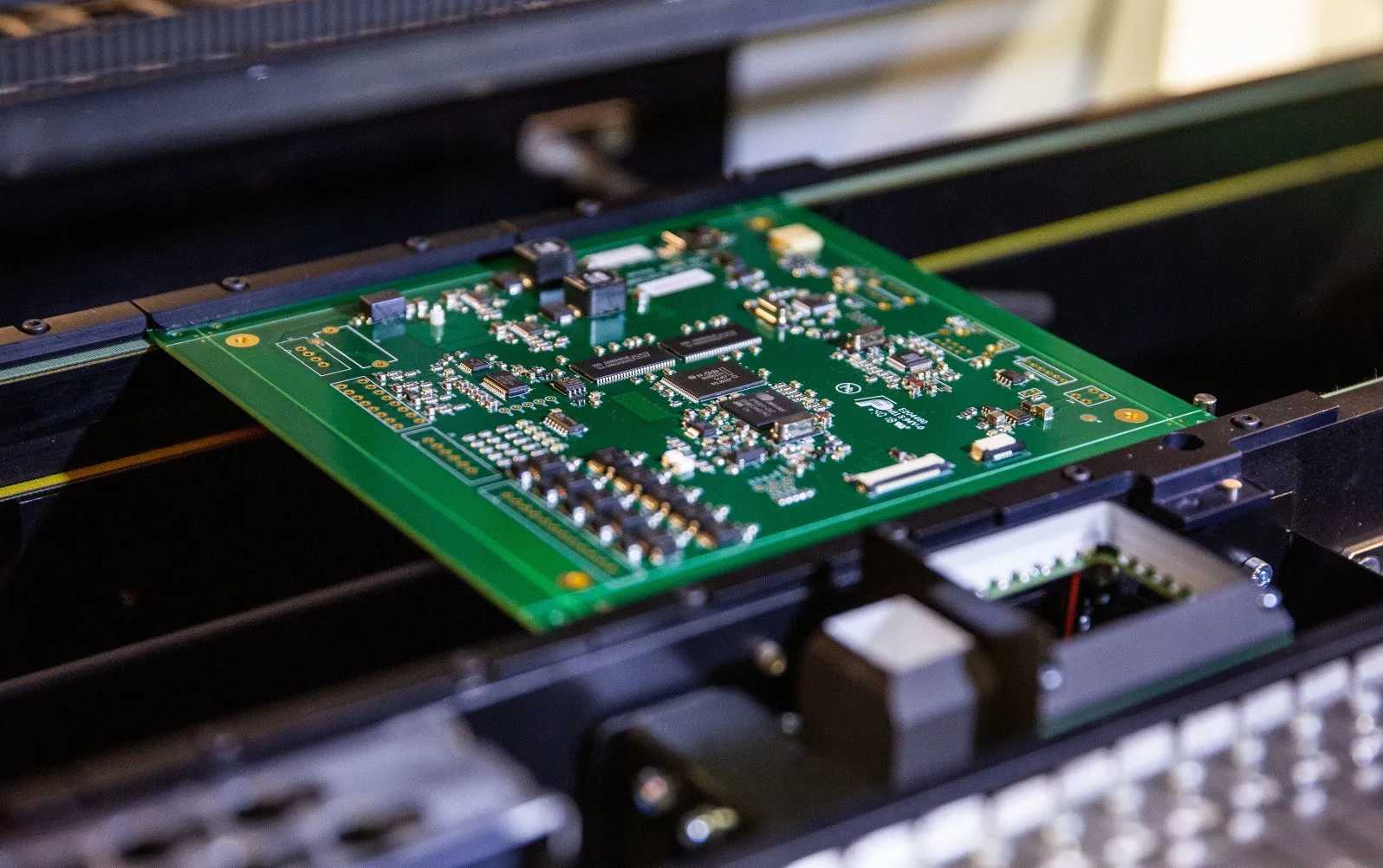

Quick turn printed circuit board (PCB) assembly refers to the rapid manufacturing of assembled PCBs on demand within a short time frame. Typically, quick turn assembly times range from 24 hours to 10 days. This accelerated service caters to prototyping needs or short production runs when having PCB assemblies fabricated and shipped fast is critical.

Choosing the right quick turn PCB assembly manufacturer requires careful vetting across a number of criteria pertaining to capabilities, quality, services, and costs. The main factors to evaluate when selecting a suitable quick turn assembly partner include:

Factors to Consider When Selecting a Quick Turn PCB Assembly Manufacturer

Capabilities

- Turnaround times – How fast can they deliver?

- Technology expertise – Do they support the latest PCB tech like HDI, flex or rigid-flex boards?

- Supply chain – Can they procure components & manage inventory effectively?

- Quality certifications – Do they have important certs like ISO 9001?

Services

- Assembly options – Do they offer SMT, thru-hole, mixed tech assembly?

- Value-added services – Do they provide DFx assistance, testing, box build, etc.?

- Supply chain support – Do they help manage bill of materials (BOM) components & logistics?

Quality

- Quality controls – Are statistical process controls and testing in place to ensure quality finished boards?

- Inspection – Are automated optical inspection (AOI) and x-ray inspection used?

Costs

- Pricing – Are their assembly costs competitive? Is there price transparency?

- NREs – What are their new project engineering charges? Are they reasonable?

This guide covers what quick turn PCB assembly is, why fast prototyping is important, the key manufacturer selection criteria, and the top quick turn assembly services to consider.

What is Quick Turn PCB Assembly?

Quick turn PCB assembly refers to the rapid fabrication, component procurement, and assembly of printed circuit boards to demanding deadlines ranging from 24 hours to 10 days.

This expedited service enables companies to obtain limited runs of assembled boards on extremely short notice. Reasons for using quick turn assembly include:

- Prototyping new designs

- Market testing concepts

- Validating functionality

- Responding urgently to customers

Quick turn capabilities essentially compress traditional PCB assembly lead times from around 4 weeks down to less than 2 weeks. This facilitates PCB prototyping iterations and market validation.

Lead Times

Typical quick turn assembly lead times are:

| Lead Time | Description |

|---|---|

| 24 Hours | Extreme rush service for simple designs |

| 2-3 Days | Rush fabrication and assembly |

| 3-5 Days | Fast building of pilot runs |

| 5-10 Days | Most common lead time for complex boards |

Of course, these aggressive lead times come at a premium cost versus standard assembly with its 4+ week turnaround.

By partnering with a competent quick turn assembly provider, companies can rapidly test concepts and ship limited runs of quality PCBs on-demand when timing is vital.

Why Fast PCB Prototyping Matters

For hardware developers, lengthy fabrication plus assembly lead times using traditional suppliers can severely slow down project progress. This makes rapid prototyping essential.

Benefits of fast PCB prototyping include:

Faster Design Iterations

- Test form, fit, and function quicker

- Identify issues early to drive improvements

- Refine optimal design faster through agile evolution

Accelerate Time-to-Market

- Prove concepts rapidly with prototypes

- Demo products sooner to secure funding

- Ship finished goods faster to beat competition

Improve Cost Efficiencies

- Fail fast, learn quick, improve ROI

- Reduce costly downstream change orders

- Derive specs accurately before mass production

For startups and established firms alike racing competitors, long design-fab-assemble cycles can mean ceding first-mover advantage.

Partnering with a quick turn assembly expert helps compress development timelines to maintain competitiveness. This makes exploring a project’s feasibility less risky by providing physical prototypes in days for engineering evaluation and market validation.

Key Criteria for Selecting a Quick Turn Assembly Partner

Vetting and choosing the right quick turn PCB assembly manufacturer for your prototyping and low-to-medium volume production needs involves assessing some important selection criteria.

Main factors to evaluate include a partner’s:

Capabilities

- Equipment & processes

- Technological expertise

- Supply chain agility

Quality & Certifications

- Quality controls

- Inspection verification

- Industry certifications

Services

- Assembly options

- Value-added services

- Supply chain support

Costs & Pricing

- Assembly costs

- NRE charges

- Price transparency

Below we explore these criteria groups more closely to understand their significance when selecting your ideal quick turn PCB assembly manufacturer.

Capabilities – Technology & Agility

You need an assembly partner equipped with advanced capabilities to build complex board designs fast and well. Look for:

Turnaround Times

- How quickly can they deliver for rush prototyping needs?

- What is their track record hitting aggressive deadlines?

PCB Technology Expertise

- Do they support advanced PCB technologies like:

- HDI boards (high density interconnect)

- Flex or rigid-flex boards

- Special materials like Rogers, polyimide

- Miniaturization needs

Supply Chain Agility

- Can they swiftly procure components & manage inventories?

- Do they provide consigned component inventory services?

Scalability

- Can they scale seamlessly as needs grow post-prototyping?

By partnering with an expert equipped with cutting-edge capabilities and supply chain agility, you gain a valuable asset supporting advanced designs, swift builds, and scalability.

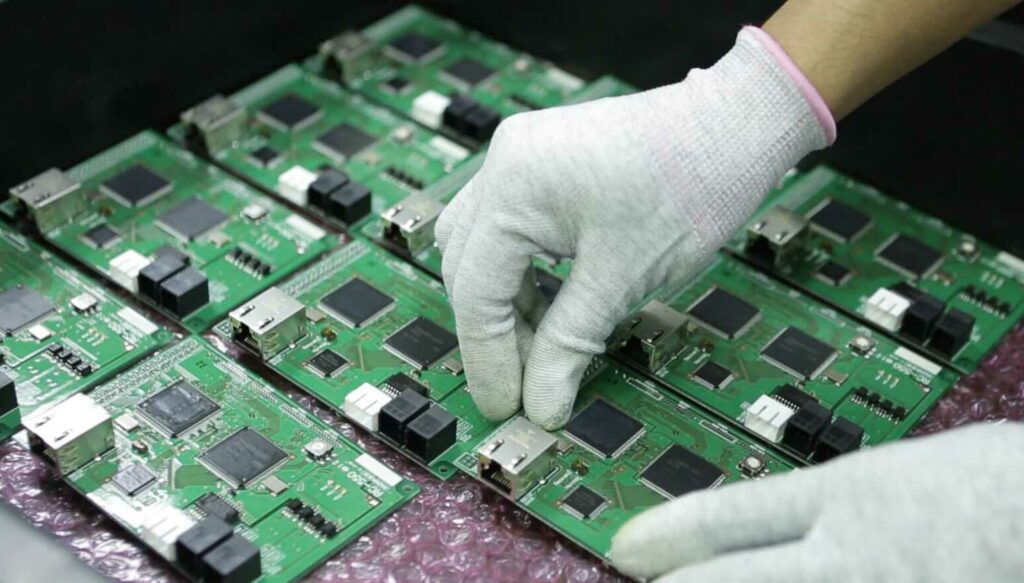

Quality & Certifications

Proven quality controls and industry certifications reassure you that assembly standards are stringent. Ensure your partner employs:

Statistical Process Controls

- Do they monitor production quality using SPC?

- What other quality controls govern assembly?

Inspection Verification

- Is automated optical inspection (AOI) used?

- Are x-rays performed to catch solder defects?

Industry Certifications

- Do they hold important operational marks like ISO 9001?

- What EMS certifications have they earned?

High-standards backed by data-driven quality frameworks, routine inspections, and certifications reflect a commitment to assembly excellence from prototype to production.

Services – Assembly, DFx, Supply Chain

Assessing service scope clarifies what value-add a prospective quick turn manufacturer provides beyond just board population. Consider:

Assembly Options

- Do they support:

- SMT assembly

- Thru-hole assembly

- Mixed SMT/thru-hole tech

- Manual assembly

- Box build services

DFx Expertise

Having design for excellence (DFx) advisory spanning manufacturability advice, DFM analysis, testability guidance, etc. helps ensure your design files smoothly transition to physical boards.

Supply Chain Assistance

- Do they help manage bill of materials (BOM) components?

- Can they procure long lead time or hard-to-find parts?

- Does their buying power make components cost competitive?

Ideally, your assembly partner helps streamline everything from advanced build processes to supply chain logistics for faster finished boards.

Costs & Pricing

Balancing project budgets and arriving at fair assembly pricing is imperative. Be clear on:

Assembly Costs

- Are their assembly prices competitive? Get price benchmarking.

- Is pricing structure and project quoting transparent?

NRE Charges

Understand all non-recurring engineering (NRE) fees upfront for:

- Design reviews

- Tooling set-up

- Test programming

Volume Scaling

- How do costs scale from prototyping to production volumes?

For budget clarity and to control project costs, have transparency from the start around pricing models, NREs, and volume-based assembly price scaling.

By finding the right quick turn PCB assembly manufacturer meeting your capability, quality, service, and pricing needs, you empower on-demand printed circuit board builds supporting rapid prototyping and scalable production.

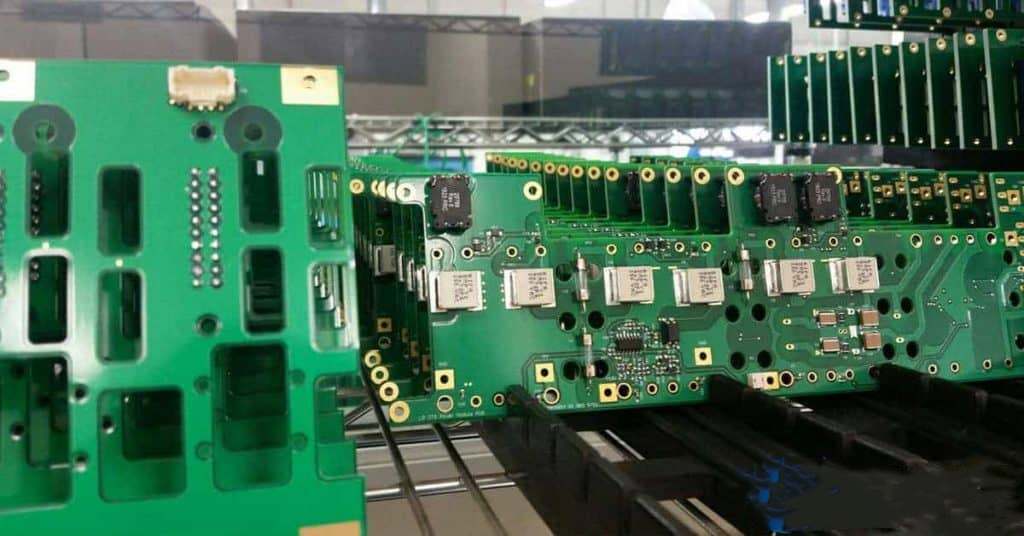

Top Quick Turn Assembly Services to Look For

Now that we have covered criteria to assess when selecting your quick turn PCB assembly partner, let’s examine some of the key assembly services you should expect.

Assembly Technology

Your manufacturer should support:

- SMT assembly

- Thru-hole assembly

- Mixed technology

- Advanced packaging

This enables assembling simple to complex boards.

Inspection

Quality inspection should include:

- Automated optical inspection (AOI)

- X-ray inspection

- Flying probe testing

Catching flaws quickly is vital.

Test Services

To validate boards function properly, testing capabilities should encompass:

- In-circuit testing

- Functional testing

- Burn-in testing

- Environmental stress testing

Thorough testing prevents field failures.

Supply Chain Management

Your assembly partner should assist with:

- Sourcing components

- Managing bill of materials (BOM)

- Inventory controls

- Kitting & shipping

Leverage their supply chain infrastructure for faster finished boards.

Design Support

To ease manufacturability, they should provide:

- Design for manufacturing (DFM) guidance

- Design for testing (DFT) input

- Technical design reviews

DFx input optimizes yield and quality.

Certifications

Reputable certifications to look for include:

- ISO 9001

- IPC 610 trusted assembly standards

- ITAR registration

Certs reassure quality focus.

Scalability

As prototypes graduate to production, your partner should offer:

- Seamless scaling of capacity

- Integration of additional services

- Continuity of quality standards

Smooth ramp-up prevents reengineering.

This mix of comprehensive capabilities and value-added services enables accelerated fabrication of quality PCB assemblies so you receive prototypes and pilot builds faster.

Frequently Asked Questions

Here are answers to some common quick turn PCB assembly FAQs.

Q: How fast can I realistically get assembled boards?

For simpler single-sided and double-sided boards without hard-to-source components, delivery in 24 to 72 hours is possible. More complex assemblies tend to require 5 to 10 day lead times.

Q: What factors impact quick turn assembly costs?

Key pricing factors include: board layer count, component types/quantities, lead times, special materials, certifications required, and production volumes needed. Understand all cost drivers.

Q: Can quick turn support advanced board technologies?

The best quick turn assembly manufacturers support the latest technologies like multi-layer boards, HDI PCBs, rigid flex circuits, and miniaturization assembly. They invest in technical capabilities supporting complex board builds.

Q: Are quick turn assemblies high quality?

Using statistical process controls, inspection verification, robust testing, and other quality best practices, competent quick turn assembly providers churn out prototypes and pilot runs meeting stringent standards for form, fit, and function.

Q: How do I scale to production volumes?

Work with your quick turn partner well in advance of expected production needs so they can allocate production capacity, order long-lead components, finalize test plans, and prepare for smooth ramp-up beyond prototyping volumes.

Finding the right quick turn PCB assembly manufacturer ensuring quality, capabilities, and affordability ultimately accelerates transforming your product ideas into physical boards ready for validation and release.