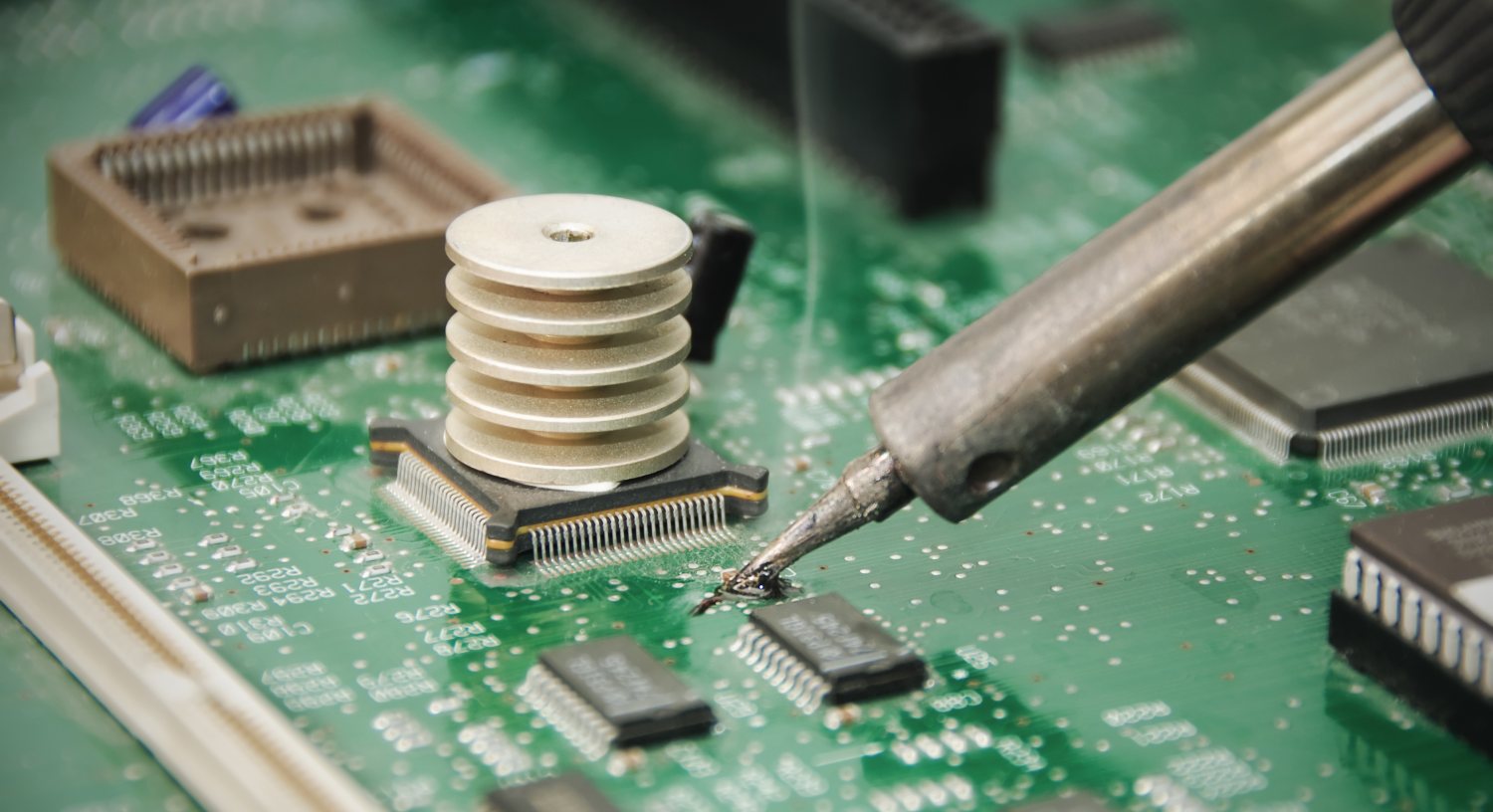

Soldering forms an essential core competency across electronics design and manufacturing. The right soldering iron serves as a fundamental tool forattaching and securing components onto printed circuit boards (PCB). With modern electronics encompassing everything from delicate surface mount ICs to high thermal mass bus bars, what soldering iron wattage makes sense for various applications?

Below covers soldering iron basics – how heat gets transferred, factors influencing ideal wattage along with recommendations on choosing the proper power across types of electronics assembly work.

How Soldering Irons Transfer Heat

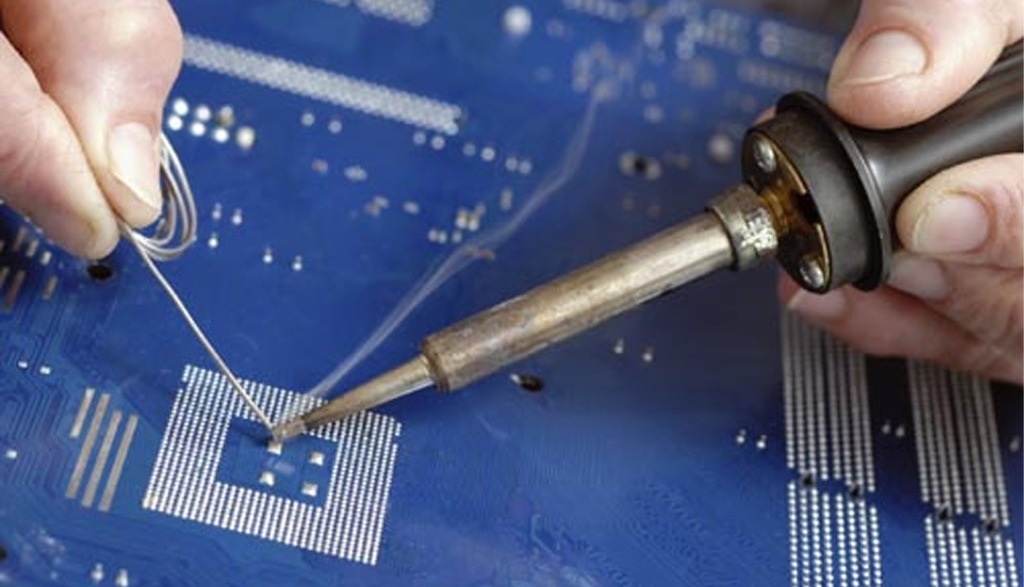

Understanding soldering iron operation helps inform appropriate power selection. Soldering involves heating metal component leads and PCB pads to melt filler alloy that mechanically and electrically bonds parts together.

Tip Temperature

The iron tip reaches approximately 700°F during soldering requiring power levels between 15 to 60 watts. Temperature exceeds the ~360°F melting point of common tin-lead and lead-free solders.

Thermal Conduction

At the joint area, heat conducts from the tip contacting the metal elements to raise the temperature enough to melt solder without overheating delicate materials.

Temperature Control

Within the iron, a heating element made from resistive nichrome wire winds around a thermal mass copper core. Temperature controlled models monitor tip temperature to regulate power.

Wattage Capacity

Power ratings on soldering irons indicate rate of thermal energy flow possible. Higher wattage allows faster heating larger joint masses by replenishing heat sink effects.

So in review, soldering irons leverage electrically heated tips to transmit thermal power into solder joints melting and fusing components. Reviewing basics helps select models appropriately.

Why Match Wattage to Application?

With heat at the core of soldering, the iron must balance transferring enough thermal energy to melt solder without risking device damage from excess temperatures. Power levels tailor capabilities.

Component Size and Thermal Mass

Higher wattages sustain necessary heat flow to mount larger components with more metal absorbing energy without cooling the connection prematurely before completed.

Temperature Sensitive Devices

Minimal necessary wattage prevents overheating vulnerable components near solder sites whether semiconductor dies, magnetic windings or plastic casings.

Repeat Soldering Cycles

Higher thermal overhead allows successive soldering connections in rapid succession by restoring heat sink effects faster for manufacturing efficiency.

Joint Access and Size

Compact, densely packed PCB assemblies require precise power control to flux and anchor joints in tight spaces without spreading excess heat across the assembly.

In summary, right-sizing the soldering iron wattage for the application prevents issues while optimizing production throughput and minimizing risks.

Soldering Iron Power Ratings

Soldering irons cover a wide span of electrical power ratings targeting different electronics assembly applications.

15 to 35 Watts

Lower power irons suit precision electronics work especially temperature sensitive components. Minimal thermal overhead prevents overheating adjoining regions. Slow heating rates limit quick successive connections.

40 to 60 Watts

Mid-range wattages handle the majority of electronics assembly tasks from wiring to PCB rework. Faster heating suits multiple quick connections while controlling heat spread into neighboring areas.

60 to 120 Watts

Higher power tools meet demands of maximizing production speed for repetitive connections while soldering larger components with high thermal dissipation. Runs hotter requiring more operator experience.

Within each range, finer 5 to 10 watt increments allow further tailoring heat delivery across project needs from microscopic soldering to fuse wires.

Recommendations by Application

Determining ideal soldering iron wattage matches power characteristic demands of the soldering application:

Circuit Board Assembly

| Project | Recommended Wattage |

|---|---|

| Precision PCB Work | 25-35W |

| Standard Through-Hole PCB | 35-45W |

| Mixed SMT/Through-Hole | 40-60W |

| High Density Surface Mount | 50-80W |

| Thermally Demanding BGAs | 80-100W |

PCB assembly spans tiny precision soldering of miniature surface mount devices to high volume assembly. Power levels accommodate component sizes and production aims.

Remedial Desoldering / Rework

| Project | Recommended Wattage |

|---|---|

| PCB Jumper Wires | 35-45W |

| Through-Hole Components | 60-80W |

| Small SMD ICs | 40-50W |

| QFP / Connectors | 70-100W |

| BGAs | 100-120W |

Desoldering and component removal often utilizes higher heat to thoroughly liquefy joints so materials cleanly release needing containment of risks from excess temperatures.

Electrical / Wiring Work

| Application | Recommended Wattage |

|---|---|

| Electronics Prototypes | 40–60W |

| 22-16 AWG Wire Splicing | 60-80W |

| Coaxial Cable Termination | 80-100W |

| Heavy Wiring Connections | 100-140W |

Beyond circuit boards, various wiring applications demand additional thermal power depending on conductor gauges and integration difficulty requiring containment of high heat.

Jewelry / Precious Metal Crafting

| Application | Recommended Wattage |

|---|---|

| Delicate Jewelry Chains | 15-25W |

| Gemstone Settings | 25-35W |

| Silver Wire Work | 35-45W |

| Small Castings | 45-60W |

Precision metalwork limits allowable heat input making fine temperature control critical for brazing delicate materials or preventing damage to nearby stones or organic components.

Soldering Iron Construction

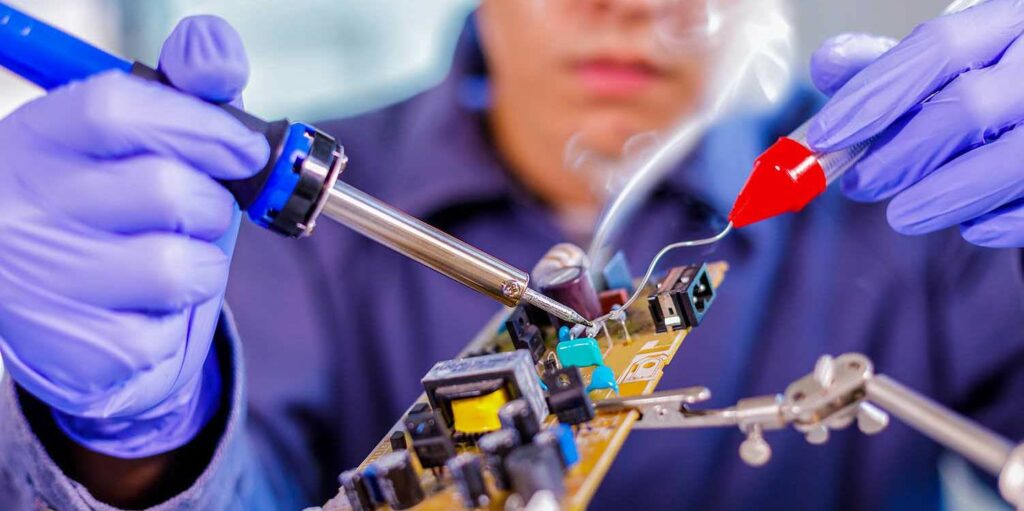

With power demands characterized, suitable iron heating element construction and tip configurations enable effective transfer into the joint.

Heating Element

High grade irons utilize pure copper cores winding thick nichrome wire for efficient thermal transfer and response. Iron plating prevents oxidation.

Tip Style

Various tapered conical, chisel, knife, hoof and screwdriver shaped tips suit needs from fine precision to max heat capacity and mechanical leverage.

Tip Coating

Plated copper or iron alloy resists oxidation while solder coats prevent sticking. Nickel or chrome better handles high temperatures and abrasion.

Handle Comfort

Smooth, contoured grips better manage prolonged assembly sessions with infrequent repositioning while avoiding sharp edges.

Cord Flexibility

Flexible power cords with appropriate insulation minimize torqueing stresses on connections to prevent shorts plus enable easier positioning.

Balance and Ergonomics

Well-balanced irons reduce fatigue and improve precision during extensive soldering allowing comfortable user experience and workmanship.

The combination of accessories to match tip style, power and stability to intended soldering tasks enhances effectiveness.

Temperature Controlled Soldering Irons

Advanced soldering irons incorporate temperature control circuitry managing heating element power to regulate tip heat. This brings useful advantages:

Consistent Working Temperature

Microprocessor monitoring maintains steady tip temperature despite variances in joint thermal load. This prevents under or overshooting temperature.

Rapid Heat Up and Recovery

Power accelerates quickly to reach setpoint faster while revitalizing heat sink effects across successive connections without needing adjustment.

Programmable Settings

Allow storing and recalling personalized temperature levels suited for specific joint types and solder melting points.

Error Detection

Alert user if tip temperature deviates outside expected ranges indicating oxidation, low power or other faults.

Increased Longevity

Actively managing element output protects against overtaxed circuits improving lifetime by avoiding prolonged peak temperatures.

Temperature controlled soldering irons provide reliable, consistent performance delivering necessary heat input to joints while protecting electronics. The precision tips the scale for intermediate to advanced users.

Soldering Iron Tips

Replaceable soldering iron tips tailor heat transfer capabilities to intended electronics assembly tasks. Key attributes differentiate capabilities:

Shape

Conical pointed shapes concentrate heat for precision applications while beveled tips suit large surface areas. Specialized shapes improve access.

Size

Tip contact size area determines maximum heat flow rate. Larger tips handle bigger joints while small tips prevent overheating tiny components.

Plating

Nickel or chrome coatings better resist corrosion while solder coats ease wetting. Copper tips handle higher temperatures with better heat conductivity.

Wetting

Sharp wettable edges soak up solder improving capillary flow while dewetting limits excess. Good thermal recovery sustains wetting across joints.

With dozens of interchangeable tip profiles, stations allow configuring the right soldering iron approach fulfilling specific operation requirements.

Soldering Process Insights

Reviewing key characteristics around