USB (Universal Serial Bus) has become the standard interface for connecting peripherals and devices to host systems like PCs, laptops and other computing platforms. USB hubs play a crucial role in expanding USB connectivity in a simple and cost-effective manner. This article provides an overview of USB hub boards – their working, types, applications and implementation in electronic systems.

What is a USB Hub?

A USB hub is a device that expands the number of USB ports available to connect devices to a host controller. It acts as a multiport repeater and enables multiple USB peripherals to be daisy chained to a single USB host port.

The USB specification allows up to 127 devices to be connected in a tiered star topology with hubs. A root hub is integrated directly in the host system. Additional hubs can be stacked in multiple tiers to increase the number of downstream ports, allowing many devices to be interfaced.

Hubs are essential in building USB systems to overcome the limited number of native USB ports in host controllers. They provide a flexible way to expand connectivity.

What is a USB Hub Board?

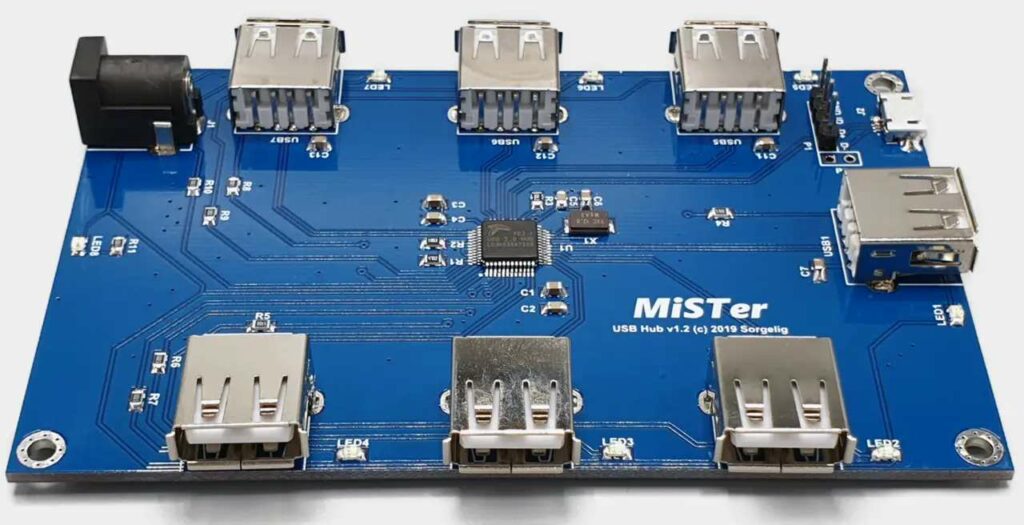

A USB hub board refers to a small printed circuit board (PCB) which implements the USB hub functionality in an integrated manner. The hub electronics are directly assembled on a PCB rather than being in a standalone plastic enclosure box.

USB hub boards offer the following advantages compared to discrete hub units:

- Compact size – Eliminates need for external casing and allows fitting hubs in tight spaces.

- Flexibility – Can be directly integrated into devices and systems as per connectivity requirements.

- Cost-effective – Eliminates the additional enclosure costs.

- Customizable – Hub circuitry can be tailored for specific port configurations and power needs.

- Reliable – Short interconnects and solid construction improve reliability over encased hubs.

Two key components in a USB hub board are:

- Hub controller IC – This is the heart of the hub which manages all downstream ports and upstream communication. It controls USB speeds, data transmission and device connections.

- Port connectors – USB type A receptacles provide the physical ports for plugging devices. Available in various port configurations e.g. 4, 7, 10.

Additionally, USB hub boards include bus power management, EMI suppression, and overcurrent protection circuits to implement robust and reliable USB expansion.

Types of USB Hub Boards

USB hub boards are available in the following common variants depending on the supported USB version and speed:

USB 2.0 Hub Boards

These boards have hub controllers which are USB 2.0 compliant. They support high speed data transfer up to 480 Mbps nominal speed. Most affordable and widely used for general USB expansion needs.

USB 3.0 Hub Boards

Boards with USB 3.0 SuperSpeed hub controllers.They add support for 5 Gbps data rates in USB 3.0 devices. Useful for high bandwidth applications. Backward compatible with USB 2.0/1.x.

USB 3.1 Hub Boards

Implement latest USB 3.1 Gen 2 specification with 10 Gbps transfer support. Also compatible with all previous USB versions. Provide future-proof solution for leading-edge USB performance.

USB-C Hub Boards

Have USB Type-C receptacles as ports instead of the larger Type-A ports. Help adopt the smaller, reversible USB-C interconnect in devices using the USB-C ports for device connections.

USB 2.0 + USB 3.0 Combo Hub Boards

Combines both USB 2.0 and USB 3.0 hub controllers on a single board to provide mixed speed ports. Allows connecting slower and faster USB peripherals to their respective compatible ports in one hub.

Bus Powered vs Self Powered Hubs

Bus powered hubs use power provided through the upstream USB port to power downstream peripheral devices. Limitation is a maximum of 4-7 downstream ports.

Self powered hubs have an onboard power supply and can support larger number of ports. Used for larger port count hubs.

Applications of USB Hub Boards

USB hub boards are extensively used in the following applications which require expanding USB connectivity:

- Laptop docking stations – Provide multiple USB ports for connecting peripherals to laptops.

- Desktop computer front panel access – Adds accessible USB ports at the front or top of desktop cases.

- Embedded systems – Add USB capabilities for connecting devices like WiFi/BT adapters, cameras, control boards in embedded products.

- Measurement instruments – USB test and measurement devices use hubs to allow both host port and multiple device ports.

- USB extenders – Extend USB cables over long distances by embedding hub boards in powered extension systems.

- USB switches – Used internally in selector switches and KVMs to allow sharing of USB peripherals between multiple host systems.

- Automotive infotainment – Add support for USB audio, video and control interfaces in cars.

- USB Dongles – Miniature hub boards enable compact USB dongles and port replicators for portable and space constrained applications.

- USB Hubs – Provide the core electronics in standalone and desktop USB hubs for connectivity expansion.

Benefits of Using USB Hub Boards

Some benefits of employing USB hub boards compared to discrete USB hub units:

- Simpler integration – Can be directly embedded into target system PCBs and enclosures.

- Compact size – Small board-level construction saves space. Enables applications like dongles.

- Flexibility – Customizable PCB configurations allow tailoring hubs as per requirements.

- Cost efficiency – Eliminates additional enclosure and assembly costs.

- Reliability – Direct port connections on PCB improves signal quality and overall robustness.

- Performance – Careful board layout preserves signal integrity for best USB speed support.

- Ease of manufacturing – Economies of scale by procuring standard hub boards vs multi-piece hubs.

- Time-to-market – Faster product development by integrating proven hub boards into designs.

Design Considerations for USB Hub Boards

Some important aspects to factor while designing and working with USB hub boards:

- Choose hub controllers carefully based on USB speeds, port count, bus/self powering needs and software requirements.

- Layout PCB for shortest port trace lengths and impedance control to prevent signal quality issues.

- Provide adequate board stack-up and ground plane layers to facilitate impedance control for USB signals.

- Carefully consider power requirements and implement robust power supply circuits, filtering, protections etc.

- Add test points, current monitoring circuits and status LEDs to enable diagnostics and debugging.

- For EMI sensitive USB 3.x implementations, choose board materials and construction to minimize EMI.

- Implement mechanisms for safe hot-plugging/unplugging of devices like electronic fuses, controller reset circuits etc.

- Evaluate need for external EEPROM configuration memory depending on hub controller used.

- Verify board dimensions and connector positioning for integration into target enclosures and systems.

- Assess reliability needs – shock, vibration, moisture, ESD – and strengthen board appropriately.

Comparison Between USB Hub Boards and Hub ICs

While hub controller ICs form the core of USB hubs, using complete hub board modules provides additional advantages:

| Parameter | Hub Controller IC | Hub Board |

|---|---|---|

| Design Complexity | High – Requires extensive external circuit design for ports, supplies, ESD protection etc. | Low – Complete USB hub function on board |

| Development Time | Long – Custom hub implementation needs to be built from scratch | Fast – Readymade hub boards allow quick integration |

| Expertise Needed | Significant USB system design expertise required | Less – Module integration requires general board design skills |

| Reliability | Lower – External circuits need to be rigorously designed | High – Qualified, proven boards lower risk |

| Cost | Low IC cost but additional PCB, components cost | Higher cost than IC alone but lower overall BOM |

| Performance | Unpredictable, depends on quality of design | Guaranteed due to rigorous design compliance |

| Customization | Fully customized to requirements | Limited flexibility – Fixed configurations |

Table 1: Comparison of USB hub ICs vs complete hub boards

Example Implementations

Some examples of how USB hub boards are integrated in electronic systems:

- Laptop docking station – A 7-port USB 3.0 hub board provides multiple peripheral ports on the dock. Allows re-using existing laptop USB ports for other needs.

- Desktop computer – 4-port USB 2.0 hub boards are used to add front panel USB ports for convenient access without opening computer case.

- Embedded controller – Miniature on-board hub board adds 2 USB ports for connecting wireless module and data storage device to the embedded system.

- Automotive center console – Custom shaped USB 3.0 hub board with dual USB-C and USB-A ports provides connectivity for car infotainment system.

- USB Dongle – Micro USB hub board with USB-A and USB-C ports packaged into a compact dongle enclosure to expand ports on laptops.

Conclusion

USB hub boards provide a flexible and efficient way to enhance USB connectivity in electronic systems without needing separate hub boxes. Integration of hub controller electronics directly on a PCB saves space and cost while enabling reliable construction. With the increasing number of USB devices, hub boards simplify adding the required number of USB ports in various applications, and help fully harness the advantages of the ubiquitous USB standard.

Frequently Asked Questions

Q: Can USB hub boards be cascaded?

A: Yes, USB hubs can be connected in tiers to expand ports further. Up to 5 tier levels are allowed in USB 2.0/1.x. For USB 3.0, only 1 additional hub tier is recommended between device and host.

Q: Do USB hub boards require drivers?

A: Most modern OS have native support for USB hubs. Additional drivers may be needed for some advanced programmable hub controllers.

Q: How are downstream data/power lines buffered in a hub?

A: Hub controllers use internal analog/digital repeaters to buffer upstream and downstream USB differential data lines. Individual port power switching/protection circuits maintain downstream power lines.

Q: Can hub ports be individually turned on/off?

A: Yes, most hub controllers provide mechanisms like port power switching, port enable/disable registers etc. to control individual port powering.

Q: What determines the maximum number of ports in a USB hub board?

A: The hub controller IC capability and available board space are key factors. For bus-powered boards, USB power budget caps total number of ports to 5-7 typically.