Introduction

In the ever-evolving world of electronics, the demand for compact, lightweight, and high-performance devices has driven the need for innovative printed circuit board (PCB) design solutions. Rigid-flex PCBs have emerged as a game-changer, combining the durability of rigid boards with the flexibility of flexible circuits. However, designing these intricate structures can be a daunting task, requiring specialized tools and techniques. Enter Altium’s 3-D PCB toolset, a comprehensive solution that streamlines the rigid-flex design process, enabling engineers to create cutting-edge products with unparalleled efficiency.

The Rise of Rigid-Flex PCBs

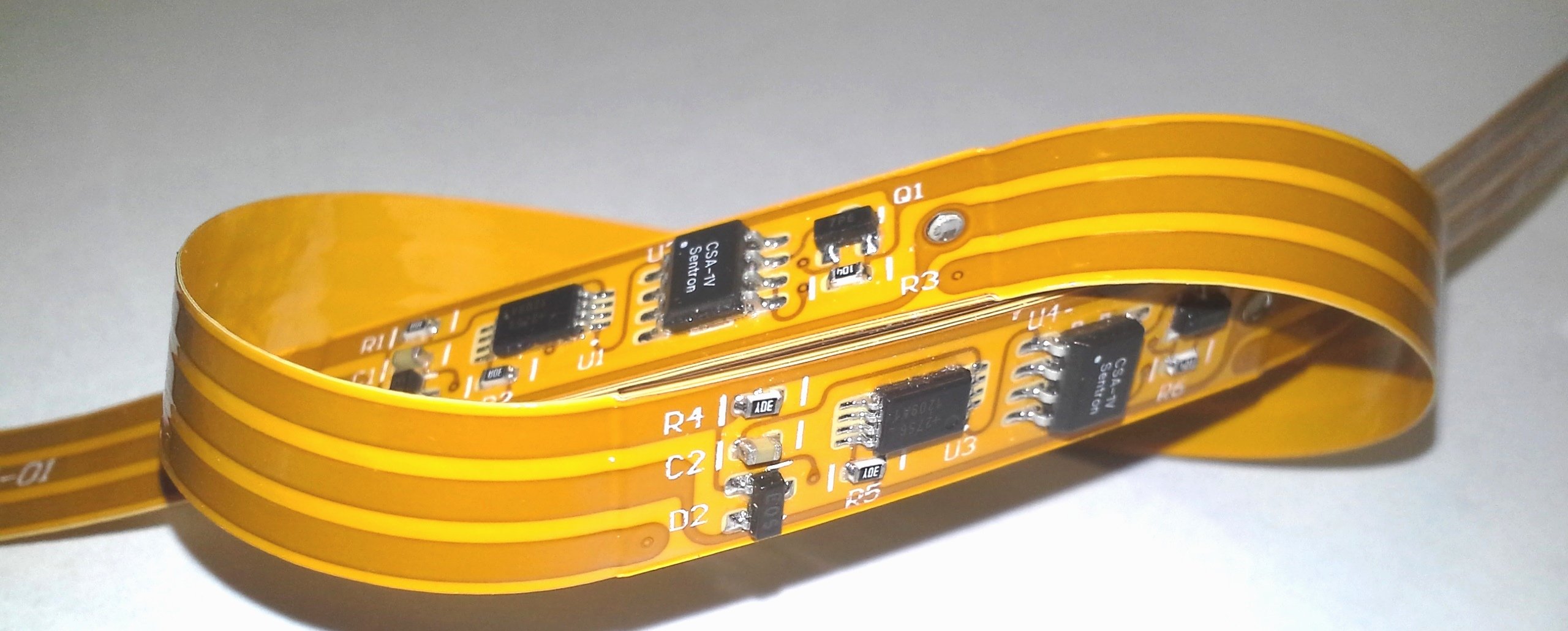

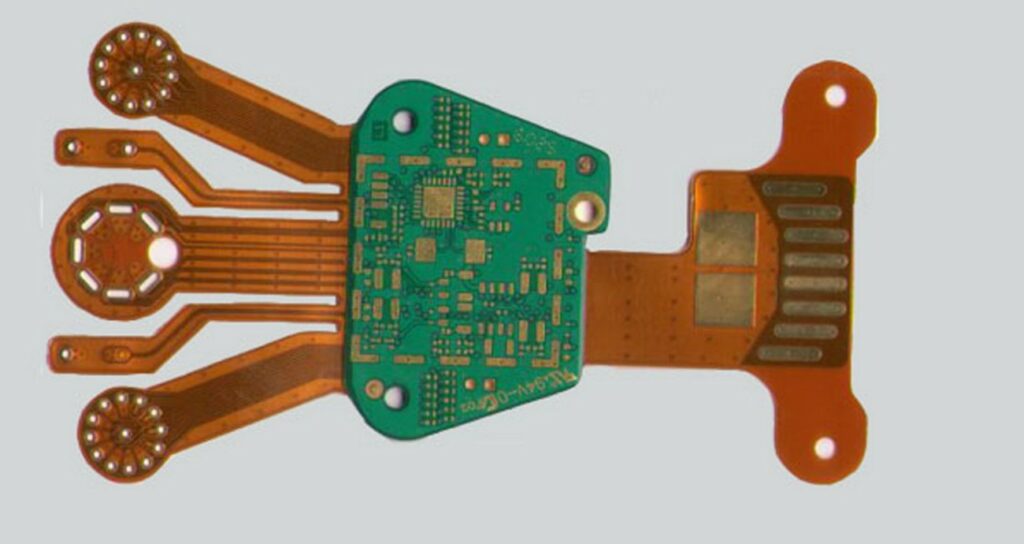

Rigid-flex PCBs have gained widespread popularity across various industries, including aerospace, medical, automotive, and consumer electronics. These hybrid circuits offer several advantages over traditional PCB designs, such as:

- Compact Form Factor: By incorporating flexible sections, rigid-flex PCBs can be folded or bent into unique shapes, allowing for efficient space utilization and minimizing the overall footprint of the device.

- Improved Reliability: The rigid sections provide structural stability, while the flexible sections absorb vibrations and thermal stresses, reducing the risk of component failure and increasing product lifespan.

- Reduced Assembly Costs: Rigid-flex PCBs eliminate the need for complex wire harnesses and connectors, streamlining the assembly process and reducing associated costs.

- Enhanced Signal Integrity: The seamless transition between rigid and flexible sections minimizes signal degradation, ensuring high-speed data transfer and optimal performance.

Despite these benefits, rigid-flex PCB design presents significant challenges. The intricate nature of these circuits, with their unique layering and bending requirements, demands specialized tools and expertise to overcome the complexities involved.

Altium’s 3-D PCB Toolset: A Game-Changer

Altium’s 3-D PCB toolset is a comprehensive software solution that addresses the challenges of rigid-flex design, providing engineers with a powerful and intuitive environment to create and validate their designs. This toolset offers a range of features and capabilities that streamline the entire design process, from concept to manufacturing.

Key Features and Capabilities

- 3-D Design Environment: Altium’s 3-D PCB toolset allows designers to work in a true 3-D environment, enabling them to visualize and manipulate their rigid-flex designs with ease. This immersive experience facilitates better design decision-making and helps identify potential issues early in the process.

- Automated Flex-Rigid Stackup Generation: The toolset simplifies the complex task of defining the stackup for rigid-flex PCBs. It automatically generates the necessary stackup based on the design requirements, ensuring accurate layer configurations and minimizing the risk of errors.

- Advanced Bend Region Management: Accurately defining and managing bend regions is crucial for rigid-flex PCB design. Altium’s toolset provides advanced tools for defining and visualizing bend regions, ensuring proper clearances, and preventing potential issues such as copper cracking or component interference.

- Intelligent Component Placement: Placing components on rigid-flex PCBs requires careful consideration of the bending regions and mechanical constraints. Altium’s toolset offers intelligent component placement capabilities, automatically suggesting optimal locations and orientations based on the design rules and constraints.

- Comprehensive Design Rule Checking (DRC): Rigid-flex PCBs have unique design rules and constraints that must be adhered to. Altium’s toolset includes a comprehensive DRC engine specifically tailored for rigid-flex designs, ensuring compliance with industry standards and minimizing potential manufacturing issues.

- Seamless Integration with Manufacturing: Altium’s 3-D PCB toolset seamlessly integrates with various manufacturing processes, including panelization, documentation generation, and output generation for fabrication and assembly. This streamlined workflow reduces the time-to-market and minimizes the risk of errors during the manufacturing process.

Benefits and Advantages

By leveraging Altium’s 3-D PCB toolset, engineers can unlock numerous benefits and advantages in their rigid-flex design projects:

- Accelerated Design Cycle: The toolset’s automated features and intelligent design capabilities significantly reduce the time and effort required for rigid-flex PCB design, enabling faster time-to-market and increased productivity.

- Reduced Design Errors: With advanced design rule checking and 3-D visualization capabilities, potential issues and design flaws can be identified and addressed early in the process, minimizing costly rework and ensuring high-quality, reliable products.

- Improved Collaboration: The 3-D design environment and seamless integration with manufacturing processes facilitate better collaboration among cross-functional teams, enabling effective communication and streamlined decision-making.

- Increased Design Flexibility: The toolset’s comprehensive feature set empowers engineers to explore and implement innovative design concepts, pushing the boundaries of what’s possible with rigid-flex PCBs.

- Cost Savings: By reducing design errors, minimizing rework, and streamlining the manufacturing process, Altium’s 3-D PCB toolset contributes to significant cost savings throughout the product development lifecycle.

Real-World Applications and Success Stories

Altium’s 3-D PCB toolset has been widely adopted by leading electronics manufacturers and innovative startups alike, enabling them to create cutting-edge products across various industries. Here are a few real-world applications and success stories:

Aerospace and Defense

- Unmanned Aerial Vehicles (UAVs): Rigid-flex PCBs play a crucial role in the design of compact and lightweight UAVs, enabling seamless integration of sensors, cameras, and communication systems. Altium’s toolset has been instrumental in the development of advanced UAV platforms, ensuring optimal performance and reliability in demanding environments.

- Satellite Systems: The extreme conditions of space require robust and reliable electronics. Rigid-flex PCBs are commonly used in satellite systems, where weight and space constraints are critical. Altium’s 3-D PCB toolset has been utilized by leading aerospace companies to design and validate rigid-flex PCBs for various satellite subsystems, ensuring mission success.

Medical Devices

- Wearable Health Monitors: The medical industry has embraced wearable devices for continuous patient monitoring and data collection. Rigid-flex PCBs enable the integration of sensors, processors, and communication modules into compact and comfortable form factors. Altium’s toolset has been instrumental in the design of these life-saving devices, ensuring reliability and accuracy while adhering to stringent medical regulations.

- Surgical Robotics: Rigid-flex PCBs are essential components in surgical robotics, enabling precise control and movement of robotic arms and instruments. Altium’s 3-D PCB toolset has been utilized by leading medical device manufacturers to design and validate rigid-flex PCBs for these innovative surgical systems, improving patient outcomes and enhancing surgical precision.

Consumer Electronics

- Foldable and Flexible Displays: The advent of foldable and flexible displays has revolutionized the consumer electronics industry. Rigid-flex PCBs are crucial in enabling these innovative display technologies, providing the necessary interconnections and structural support. Altium’s toolset has played a pivotal role in the design of these cutting-edge devices, helping manufacturers stay ahead of the curve.

- Wearable Technology: From fitness trackers to augmented reality glasses, wearable technology relies heavily on rigid-flex PCBs to achieve compact and ergonomic designs. Altium’s 3-D PCB toolset has been instrumental in the development of these consumer electronics products, ensuring seamless integration of various components and optimal user experience.

These real-world applications and success stories highlight the versatility and impact of Altium’s 3-D PCB toolset in enabling innovative rigid-flex designs across diverse industries. As technology continues to evolve, this powerful toolset will remain a driving force in pushing the boundaries of what’s possible with rigid-flex PCBs.

Frequently Asked Questions (FAQ)

- What sets Altium’s 3-D PCB toolset apart from other rigid-flex design solutions? Altium’s 3-D PCB toolset stands out with its comprehensive feature set and seamless integration of the entire design process. From the intuitive 3-D design environment to advanced bend region management, intelligent component placement, and seamless manufacturing integration, this toolset provides a complete solution tailored specifically for rigid-flex PCB design.

- Can Altium’s toolset handle complex rigid-flex designs with multiple bending regions? Yes, Altium’s 3-D PCB toolset is capable of handling even the most complex rigid-flex designs with multiple bending regions. The advanced bend region management tools allow designers to define and visualize these regions with precision, ensuring proper clearances and preventing potential issues.

- How does Altium’s toolset ensure compliance with industry standards and design rules? Altium’s toolset includes a comprehensive Design Rule Checking (DRC) engine specifically tailored for rigid-flex PCBs. This DRC engine enforces compliance with industry standards and design rules, ensuring that the final design meets all necessary requirements and minimizing the risk of manufacturing issues.

- Can Altium’s 3-D PCB toolset be integrated with existing design workflows and processes? Absolutely. Altium’s toolset is designed to seamlessly integrate with existing design workflows and processes. It supports various file formats and can be easily incorporated into existing design environments, facilitating a smooth transition and minimizing disruption to existing workflows.

- What kind of support and resources are available for Altium’s 3-D PCB toolset users? Altium offers comprehensive support and resources for its users. This includes extensive documentation, online tutorials, user forums, and dedicated technical support channels. Additionally, Altium hosts regular webinars, training sessions, and user group meetings to ensure users stay up-to-date with the latest features and best practices.

Conclusion

In the ever-evolving landscape of electronics design, rigid-flex PCBs have emerged as a game-changing solution, offering unparalleled flexibility, reliability, and performance. However, designing these intricate structures poses significant challenges that require specialized tools and expertise.

Altium’s 3-D PCB toolset addresses these challenges head-on, providing a comprehensive and intuitive solution for rigid-flex design. With its advanced features, such as 3-D design environment, automated flex-rigid stackup generation, intelligent component placement, and seamless manufacturing integration, this toolset empowers engineers to create cutting-edge products with unparalleled efficiency.

As the demand for compact, lightweight, and high-performance devices continues to grow, Altium’s 3-D PCB toolset positions itself as a game-changer, enabling designers to push the boundaries of what’s possible with rigid-flex PCBs. From aerospace and defense to medical devices and consumer electronics, this powerful toolset has already proven its worth, enabling innovative designs and driving technological advancements across diverse industries.

Whether you’re a seasoned rigid-flex designer or embarking on your first project, Altium’s 3-D PCB toolset offers a comprehensive and user-friendly solution that streamlines the entire design process, enabling you to bring your most ambitious ideas to life with confidence and precision.