Introduction

In the ever-evolving world of electronics, printed circuit boards (PCBs) have become an integral part of virtually every electronic device we use. From computers and smartphones to televisions and automobiles, PCBs are the backbone of modern electronics, enabling the seamless integration of various components and facilitating the flow of signals and power. However, as electronic devices become more complex and demanding, the traditional concept of PCBs has evolved into a more specialized and advanced form – the PCB printed signal board.

A PCB printed signal board, also known as a high-speed or high-frequency PCB, is a type of printed circuit board designed specifically for applications that require the transmission of high-speed digital or radio frequency (RF) signals. These boards are engineered to minimize signal distortion, crosstalk, and electromagnetic interference (EMI), ensuring reliable and efficient signal propagation.

The Importance of PCB Printed Signal Boards

In today’s digital age, the demand for high-speed data transfer and communication has skyrocketed. From high-definition multimedia streaming to wireless networking and advanced computing, the need for reliable and high-performance signal transmission has become paramount. PCB printed signal boards play a crucial role in meeting these demands by providing the necessary infrastructure for high-speed signal propagation.

These specialized boards find applications in a wide range of industries, including:

- Telecommunications

- Computer networking

- Aerospace and defense

- Automotive electronics

- Consumer electronics

- Medical devices

By ensuring the integrity of high-speed signals, PCB printed signal boards enable the development of cutting-edge technologies and devices that push the boundaries of performance and functionality.

Design Considerations for PCB Printed Signal Boards

The design and manufacturing of PCB printed signal boards involve several critical considerations to ensure optimal signal integrity and performance. Here are some key factors that engineers must take into account:

1. Signal Integrity

Signal integrity is of paramount importance in high-speed and high-frequency applications. Factors such as impedance matching, crosstalk, and signal reflections can significantly impact signal quality and overall performance. Proper trace routing, controlled impedance lines, and careful consideration of return paths are essential to maintain signal integrity.

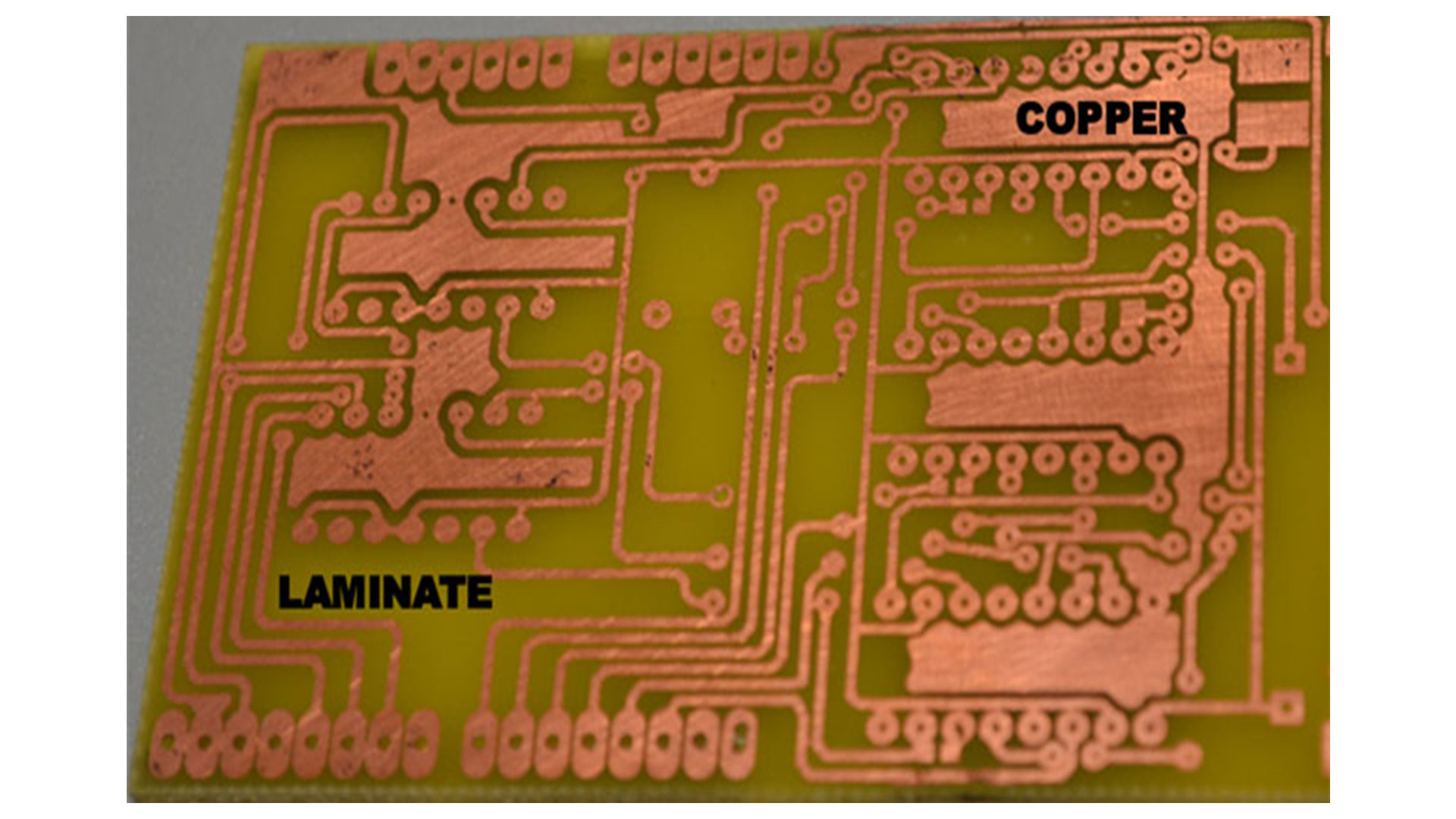

2. Materials and Substrate Selection

The choice of materials and substrates used in the construction of PCB printed signal boards plays a crucial role in their performance. High-frequency laminates, such as FR-4, polyimide, and PTFE, are commonly used due to their low dielectric loss and consistent electrical properties over a wide range of frequencies.

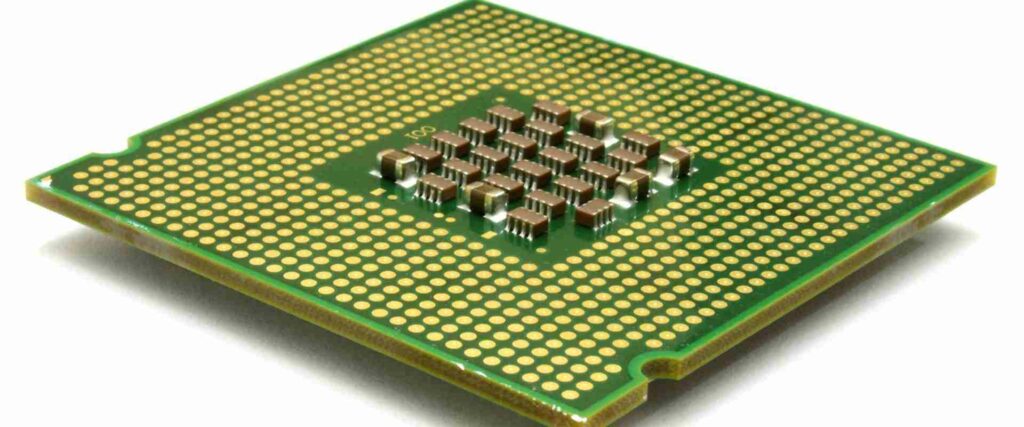

3. Stackup Design

The stackup design, which refers to the arrangement and thickness of the various layers within the PCB, is a critical factor in ensuring signal integrity and minimizing electromagnetic interference. Careful consideration of layer spacing, ground plane placement, and via transitions is essential for optimal signal propagation.

4. Trace Geometry and Routing

The geometry and routing of traces on PCB printed signal boards significantly influence signal quality. Factors such as trace width, spacing, and length must be carefully designed to maintain impedance control and minimize signal reflections and crosstalk.

5. Power Integrity

Power integrity is another crucial aspect of PCB printed signal boards. Proper power plane design, decoupling capacitor placement, and power distribution strategies are necessary to ensure stable and reliable power delivery to the various components on the board.

6. Electromagnetic Compatibility (EMC)

PCB printed signal boards must comply with electromagnetic compatibility (EMC) standards to minimize the emission and susceptibility to electromagnetic interference. This involves proper shielding, grounding, and filtering techniques to ensure the board operates reliably in its intended environment.

Manufacturing Considerations

The manufacturing process for PCB printed signal boards requires advanced techniques and strict quality control measures to ensure consistent performance and reliability. Some key considerations include:

- Controlled Impedance Fabrication

- High-Precision Drilling and Plating

- Strict Cleanliness Standards

- Advanced Testing and Verification

Specialized fabrication facilities and equipment are often required to meet the stringent demands of high-speed and high-frequency PCB manufacturing.

Applications of PCB Printed Signal Boards

PCB printed signal boards find applications in a wide range of industries and products, enabling the development of advanced technologies and cutting-edge devices. Here are some notable examples:

1. Telecommunications

In the telecommunications industry, PCB printed signal boards are essential for high-speed data transmission and communication systems. They are used in various equipment, such as routers, switches, base stations, and mobile devices, enabling reliable and high-bandwidth data transfer.

2. Computer Networking

High-speed computer networking relies heavily on PCB printed signal boards to facilitate data transfer between devices and servers. These boards are found in network interface cards, switches, routers, and other networking equipment, enabling fast and efficient communication within local area networks (LANs) and wide area networks (WANs).

3. Aerospace and Defense

The aerospace and defense sectors demand high-performance and reliable electronic systems. PCB printed signal boards are used in various applications, including radar systems, avionics, satellite communications, and military-grade electronics, where signal integrity and EMC compliance are critical.

4. Automotive Electronics

As modern vehicles become increasingly reliant on advanced electronics and communication systems, PCB printed signal boards play a vital role in enabling reliable data transfer and signal processing. These boards are found in various automotive applications, such as infotainment systems, advanced driver assistance systems (ADAS), and vehicle-to-vehicle (V2V) communication systems.

5. Consumer Electronics

In the consumer electronics market, PCB printed signal boards are essential for enabling high-speed data transfer and communication in devices such as smartphones, laptops, gaming consoles, and high-definition multimedia devices. They ensure reliable and high-performance signal transmission, enabling seamless user experiences.

6. Medical Devices

The medical industry relies on accurate and reliable electronic devices for diagnostic and therapeutic purposes. PCB printed signal boards are used in various medical equipment, such as imaging systems, patient monitoring devices, and surgical instruments, where signal integrity and EMC compliance are crucial for ensuring accurate and safe operation.

Future Trends and Challenges

As technology continues to evolve and demand for higher data rates and faster signal processing increases, the role of PCB printed signal boards will become even more critical. Here are some future trends and challenges in this field:

- Higher Frequencies and Data Rates

- Miniaturization and Density Challenges

- Advanced Materials and Manufacturing Techniques

- Thermal Management Considerations

- Emerging Applications (5G, Internet of Things, Autonomous Vehicles)

Engineers and researchers are continuously exploring new design techniques, materials, and manufacturing processes to address these challenges and enable the development of more advanced and high-performance PCB printed signal boards.

Frequently Asked Questions (FAQs)

- What is the difference between a standard PCB and a PCB printed signal board? A PCB printed signal board, also known as a high-speed or high-frequency PCB, is specifically designed for applications that require the transmission of high-speed digital or radio frequency (RF) signals. These boards are engineered to minimize signal distortion, crosstalk, and electromagnetic interference (EMI), ensuring reliable and efficient signal propagation. Standard PCBs, on the other hand, are designed for lower-speed applications and may not have the same level of signal integrity and performance as PCB printed signal boards.

- Why is signal integrity so important in PCB printed signal boards? Signal integrity is crucial in PCB printed signal boards because any distortion, reflections, or crosstalk in high-speed or high-frequency signals can lead to data corruption, decreased performance, or even system failures. These boards are designed to maintain signal quality and minimize interference, ensuring reliable and accurate data transmission.

- What materials are commonly used in the construction of PCB printed signal boards? High-frequency laminates, such as FR-4, polyimide, and PTFE, are commonly used in the construction of PCB printed signal boards due to their low dielectric loss and consistent electrical properties over a wide range of frequencies. The choice of materials depends on factors such as operating frequency, signal integrity requirements, and environmental conditions.

- How does the stackup design affect the performance of PCB printed signal boards? The stackup design, which refers to the arrangement and thickness of the various layers within the PCB, plays a crucial role in ensuring signal integrity and minimizing electromagnetic interference. Careful consideration of layer spacing, ground plane placement, and via transitions is essential for optimal signal propagation and minimizing crosstalk.

- What are some common applications of PCB printed signal boards? PCB printed signal boards find applications in a wide range of industries and products, including telecommunications (routers, switches, base stations), computer networking (network interface cards, switches, routers), aerospace and defense (radar systems, avionics, satellite communications), automotive electronics (infotainment systems, ADAS, V2V communication), consumer electronics (smartphones, laptops, gaming consoles), and medical devices (imaging systems, patient monitoring devices, surgical instruments).