Introduction

In today’s world of portable electronic devices, efficient battery management has become a crucial aspect of hardware design. As devices become more power-hungry and battery life remains a significant concern for users, the need for accurate battery level monitoring has become increasingly important. A battery level monitor circuit is an essential component that helps track the remaining charge in a battery, enabling users to estimate the remaining operating time and plan for recharging or battery replacement.

This article will delve into the intricacies of battery level monitor circuits, exploring their design principles, components, and implementation strategies. We will also discuss the various methods for measuring battery voltage and converting it into a meaningful representation of the remaining battery capacity.

Understanding Battery Characteristics

Before delving into the design of a battery level monitor circuit, it is essential to understand the fundamental characteristics of batteries and how they relate to battery level monitoring.

Battery Chemistry

Different battery chemistries exhibit varying properties and behaviors, which can influence the design of the monitoring circuit. Common battery types include:

- Lead-acid batteries

- Lithium-ion (Li-ion) batteries

- Nickel-cadmium (NiCd) batteries

- Nickel-metal hydride (NiMH) batteries

Each battery chemistry has unique voltage characteristics, discharge curves, and temperature dependencies that must be considered when designing a battery level monitor circuit.

Battery Discharge Curve

The discharge curve of a battery represents the relationship between the battery’s terminal voltage and its remaining capacity (or state of charge). As a battery discharges, its terminal voltage gradually decreases, following a characteristic curve that varies depending on the battery chemistry and load conditions.

Understanding the discharge curve is crucial for accurately interpreting the battery’s voltage readings and converting them into a meaningful representation of the remaining capacity.

Battery Self-Discharge

Self-discharge is a phenomenon where a battery gradually loses its charge even when it is not being used. This effect is more pronounced in certain battery chemistries, such as NiCd and NiMH batteries, and can impact the accuracy of battery level monitoring if not accounted for.

Battery Level Monitoring Methods

There are various methods for monitoring the battery level, each with its own advantages and limitations. The choice of method depends on factors such as the required accuracy, cost, and complexity of implementation.

Voltage-Based Monitoring

Voltage-based monitoring is one of the simplest and most commonly used methods for battery level monitoring. It involves measuring the battery’s terminal voltage and correlating it with the remaining capacity using a predefined discharge curve or lookup table.

The main advantage of this method is its simplicity and low cost, as it requires only a voltage divider circuit and an analog-to-digital converter (ADC) or a comparator circuit. However, its accuracy can be limited, particularly when the battery is heavily loaded or when the discharge curve is affected by factors such as temperature or aging.

Coulomb Counting

Coulomb counting, also known as current integration, is a more accurate method for battery level monitoring. It involves measuring the current flowing into or out of the battery and integrating it over time to estimate the remaining capacity.

This method relies on the principle that the battery’s capacity is directly related to the amount of charge (measured in coulombs) that has been removed or added to the battery. By continuously tracking the charge flow, the remaining capacity can be calculated with a high degree of accuracy.

However, coulomb counting requires additional hardware, such as a precision current sensing circuit and a microcontroller or dedicated integrated circuit (IC) for performing the integration calculations. It is also susceptible to accumulated errors over time, which may require periodic calibration or resetting.

Impedance Tracking

Impedance tracking is another method for battery level monitoring that relies on the relationship between a battery’s internal impedance and its state of charge. As a battery discharges, its internal impedance changes due to chemical and physical processes within the cell.

By measuring the battery’s impedance at a specific frequency or using electrochemical impedance spectroscopy (EIS), it is possible to estimate the remaining capacity. This method can provide accurate results, particularly for certain battery chemistries, such as lead-acid batteries.

However, impedance tracking requires specialized hardware and signal processing techniques, which can increase the complexity and cost of the monitoring circuit.

Hybrid Approaches

In some cases, a combination of multiple methods may be used to improve the overall accuracy and reliability of battery level monitoring. For example, a system may use voltage-based monitoring as the primary method, combined with coulomb counting or impedance tracking for periodic calibration or cross-checking.

Hybrid approaches can leverage the strengths of different methods while compensating for their individual limitations, resulting in a more robust and accurate battery level monitoring solution.

Circuit Design Considerations

When designing a battery level monitor circuit, several factors must be taken into account to ensure accurate and reliable performance.

Analog Front-End Design

The analog front-end of the battery level monitor circuit is responsible for measuring the battery’s voltage, current, or impedance, depending on the chosen monitoring method. Proper design of the analog front-end is crucial for achieving accurate and noise-free measurements.

Key considerations include:

- Voltage divider design for voltage measurement

- Current sensing techniques (shunt resistors, Hall effect sensors, etc.)

- Noise filtering and signal conditioning

- Analog-to-digital converter (ADC) selection and configuration

Microcontroller or Dedicated IC Selection

Depending on the complexity of the monitoring method and the required features, a microcontroller or dedicated integrated circuit (IC) may be needed for data processing, calculations, and user interface management.

When selecting a microcontroller or IC, factors such as processing power, memory, peripherals, power consumption, and development tools should be considered. Additionally, the availability of software libraries or firmware for battery level monitoring can significantly simplify the implementation.

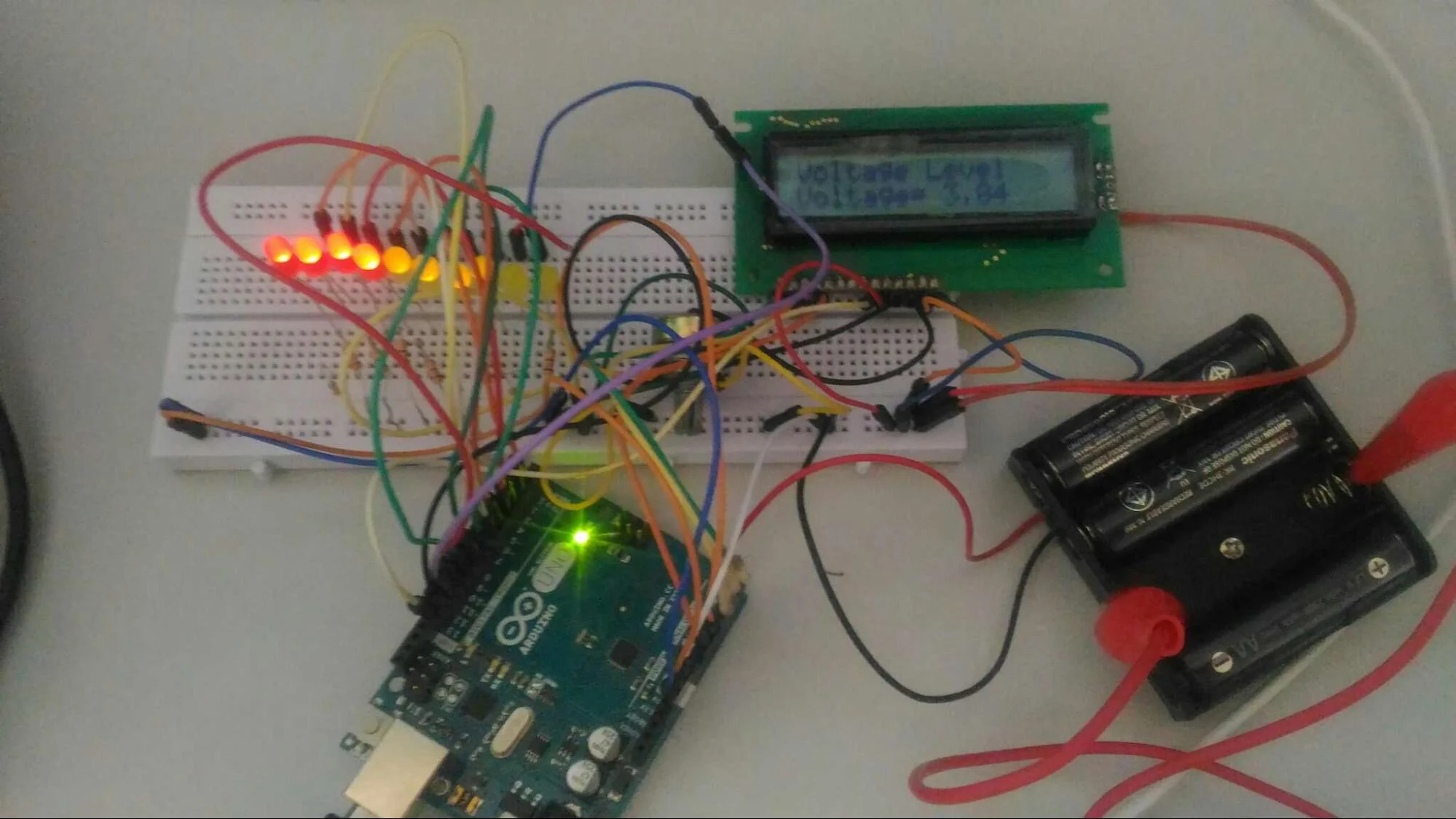

User Interface and Display

A user-friendly interface and display are essential for providing meaningful feedback to the user about the battery’s remaining capacity. This can range from simple LED indicators to more advanced graphical displays or numerical readouts.

The choice of display technology (e.g., LCD, OLED, e-ink) and the design of the user interface should consider factors such as power consumption, visibility in different lighting conditions, and ease of use.

Power Management

Power management is a critical aspect of battery level monitor circuit design, as the monitoring circuit itself consumes power and can impact the overall battery life. Techniques such as low-power modes, sleep/wake cycles, and efficient power supply design can help minimize the power consumption of the monitoring circuit.

Temperature Compensation

Battery performance and characteristics can be affected by temperature variations. To maintain accurate battery level monitoring, it may be necessary to incorporate temperature compensation techniques into the circuit design.

This can involve temperature sensing, lookup tables, or mathematical models to adjust the monitoring algorithm based on the measured temperature.

Implementation Strategies

There are several implementation strategies for battery level monitor circuits, ranging from discrete component designs to integrated solutions. The choice of strategy depends on factors such as cost, complexity, and performance requirements.

Discrete Component Design

In a discrete component design, the battery level monitor circuit is built using individual components such as operational amplifiers, comparators, resistors, and capacitors. This approach offers flexibility and customization but requires careful component selection, layout, and calibration.

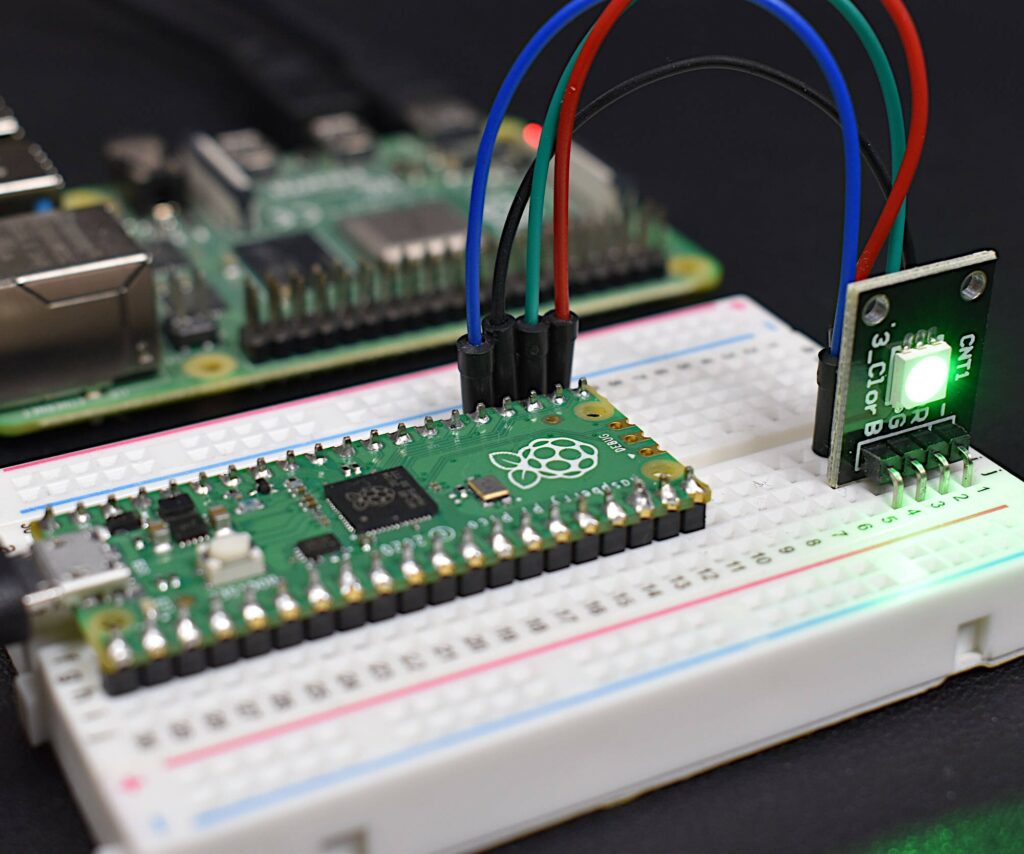

Microcontroller-Based Design

A microcontroller-based design incorporates a microcontroller or microprocessor as the central processing unit for the battery level monitor circuit. This approach offers programmability, versatility, and the ability to integrate additional features or algorithms.

Microcontroller-based designs may require more development effort and programming expertise but can provide a more comprehensive and intelligent battery management solution.

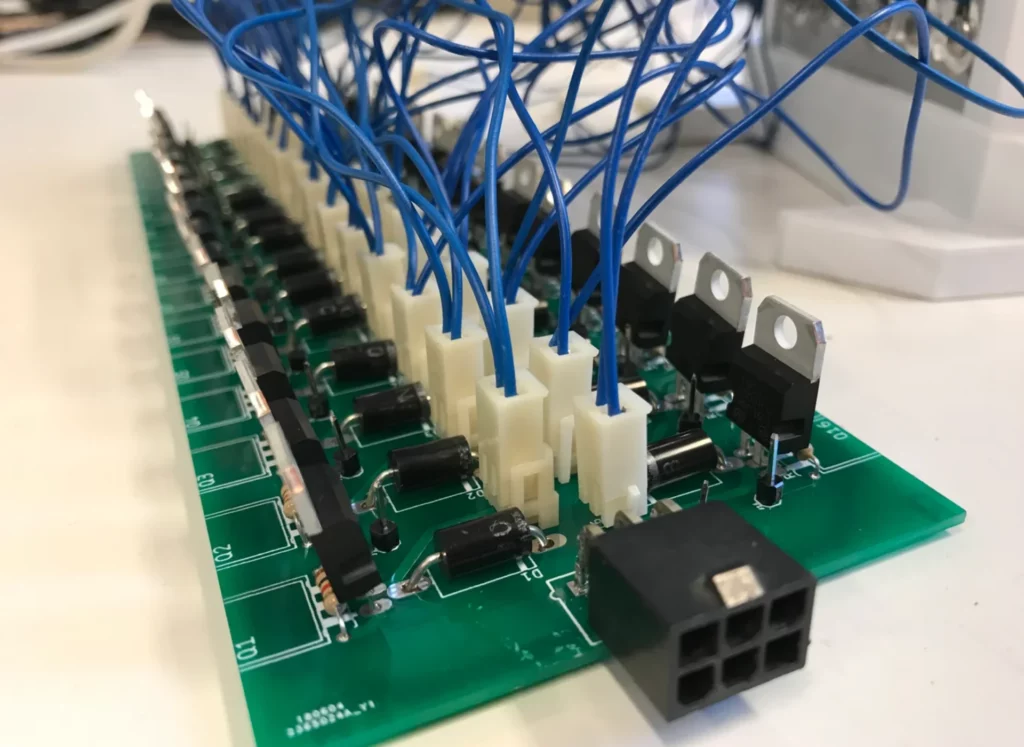

Dedicated Integrated Circuit (IC) Solutions

Several semiconductor manufacturers offer dedicated integrated circuits (ICs) specifically designed for battery level monitoring and fuel gauging applications. These ICs integrate various monitoring methods, such as voltage measurement, coulomb counting, and impedance tracking, into a single package.

Using a dedicated IC can simplify the design process and provide a more compact and power-efficient solution. However, these ICs may have limited flexibility and may require additional external components or programming for specific applications.

System-on-Chip (SoC) Integration

In some cases, battery level monitoring functionality can be integrated into a larger system-on-chip (SoC) design, combining the monitoring circuit with other components such as microcontrollers, power management units, or wireless communication modules.

This approach can lead to a more compact and cost-effective solution but may require careful consideration of power consumption, thermal management, and potential interference between different functional blocks.

Applications and Use Cases

Battery level monitor circuits find applications in a wide range of portable electronic devices and systems that rely on battery power. Some common use cases include:

Consumer Electronics

- Smartphones

- Tablets

- Laptops

- Wearable devices (smartwatches, fitness trackers)

- Portable media players

- Digital cameras

Industrial and Automotive Applications

- Portable instrumentation and data loggers

- Handheld scanners and barcode readers

- Remote control units

- Automotive battery monitoring and management systems

- Uninterruptible power supplies (UPS)

Renewable Energy Systems

- Solar-powered devices and systems

- Wind turbine monitoring and control

- Energy storage systems

Medical Devices

- Portable medical equipment (e.g., patient monitors, infusion pumps)

- Implantable medical devices (e.g., pacemakers, defibrillators)

Internet of Things (IoT) and Wireless Sensor Networks

- Battery-powered IoT devices and sensors

- Remote monitoring and control applications

Frequently Asked Questions (FAQ)

- What is the difference between voltage-based and coulomb counting methods for battery level monitoring?

Voltage-based monitoring measures the battery’s terminal voltage and correlates it with the remaining capacity using a predefined discharge curve or lookup table. It is a simple and low-cost method but can have limited accuracy, particularly when the battery is heavily loaded or when the discharge curve is affected by factors such as temperature or aging.

Coulomb counting, on the other hand, involves measuring the current flowing into or out of the battery and integrating it over time to estimate the remaining capacity. It is generally more accurate than voltage-based monitoring but requires additional hardware and computational resources. Coulomb counting is also susceptible to accumulated errors over time, which may require periodic calibration or resetting.

- How does temperature affect battery level monitoring accuracy?

Temperature can significantly impact battery performance and characteristics, affecting the accuracy of battery level monitoring. At lower temperatures, batteries may exhibit reduced capacity and higher internal resistance, while at higher temperatures, they may experience accelerated self-discharge and reduced cycle life.

To maintain accurate battery level monitoring, it is often necessary to incorporate temperature compensation techniques into the circuit design. This can involve temperature sensing, lookup tables, or mathematical models to adjust the monitoring algorithm based on the measured temperature.

- What are the advantages and disadvantages of using a dedicated integrated circuit (IC) for battery level monitoring?

The main advantage of using a dedicated IC for battery level monitoring is the integration of various monitoring methods, such as voltage measurement, coulomb counting, and impedance tracking, into a single package. This can simplify the design process and provide a more compact and power-efficient solution.

However, dedicated ICs may have limited flexibility and may require additional external components or programming for specific applications. They can also be more expensive than discrete component designs, especially for low-volume or prototyping applications.

- How does battery self-discharge affect battery level monitoring?

Battery self-discharge is a phenomenon where a battery gradually loses its charge even when it is not being used. This effect is more pronounced in certain battery chemistries, such as NiCd and NiMH batteries, and can impact the accuracy of battery level monitoring if not accounted for.

If self-discharge is not considered, the battery level monitor may overestimate the remaining capacity, leading to premature battery depletion or unexpected device shutdowns. To compensate for self-discharge, battery level monitoring algorithms may incorporate self-discharge models or periodic calibration routines to maintain accurate capacity estimates.

- What are some common user interface and display options for battery level monitor circuits?

User interface and display options for battery level monitor circuits can range from simple LED indicators to more advanced graphical displays or numerical readouts. Common options include:

- LED indicators (e.g., a series of LEDs representing different battery levels)

- Segmented LCD or OLED displays showing a numerical or bar graph representation of the remaining capacity

- Graphical LCD or OLED displays with more detailed battery information and user interfaces

- Integration with a device’s existing display or user interface

The choice of display technology and user interface design should consider factors such as power consumption, visibility in different lighting conditions, and ease of use for the target application.