Description

Gold Finger PCB (Printed Circuit Board) Manufacturing is a specialized process used to produce high-quality and reliable PCBs for various electronics applications. Here are some key points about Gold Finger PCB Manufacturing:

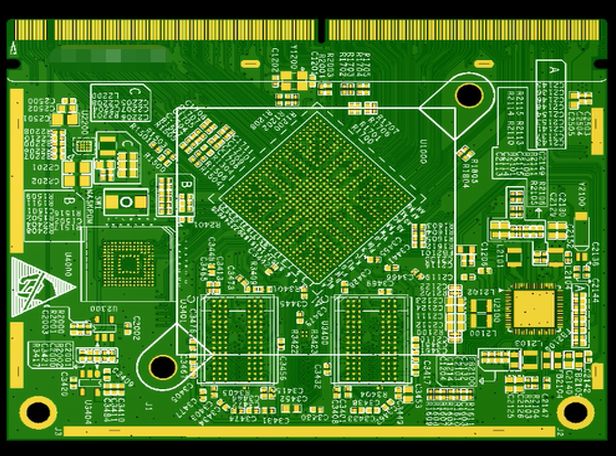

- Gold Fingers: The term “gold fingers” refers to the gold-plated edge connectors on PCBs. These gold-plated fingers provide a low-resistance electrical connection and ensure a stable interface between the PCB and other components or connectors.

- Purpose: Gold Finger PCBs are commonly used in applications that require high-reliability connections, such as telecommunications equipment, servers, routers, and other high-end electronics. The gold plating enhances durability, corrosion resistance, and conductivity, ensuring long-lasting performance.

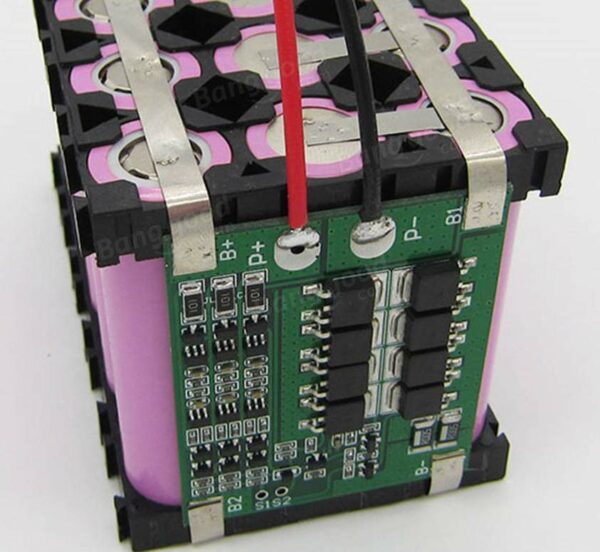

- Manufacturing Process: The gold finger manufacturing process typically involves the following steps: a. Base material preparation: A copper-clad laminate (e.g., FR4, polyimide) is used as the base material for the PCB. b. Copper patterning: The copper layer is etched or patterned to create the desired circuit traces and component pads. c. Gold plating: The edge connectors or “fingers” are selectively plated with a thin layer of gold, typically using an electroplating process. d. Surface finishing: Additional surface treatments, such as nickel-gold plating or immersion tin, may be applied to enhance solderability and corrosion resistance.

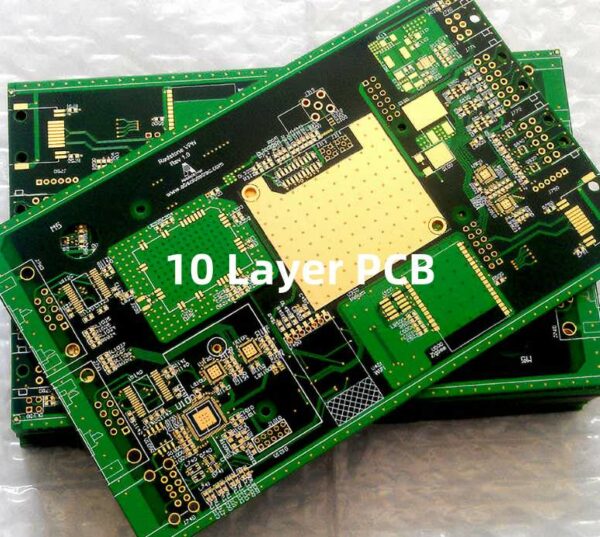

- Gold Plating Thickness: The thickness of the gold plating on the fingers is typically between 0.5 microns and 2.5 microns, depending on the application and desired durability.

- Quality Control: Strict quality control measures are implemented during the manufacturing process to ensure consistent gold plating thickness, adhesion, and overall PCB reliability.

- Applications: Gold Finger PCBs are widely used in various industries, including telecommunications, aerospace, military, medical equipment, and high-end consumer electronics, where reliable and durable connections are critical.

Gold Finger PCB Manufacturing is a specialized process that requires precise control over materials, plating processes, and quality assurance procedures. It is essential for applications that demand high-reliability and long-lasting performance in demanding environments.