Description

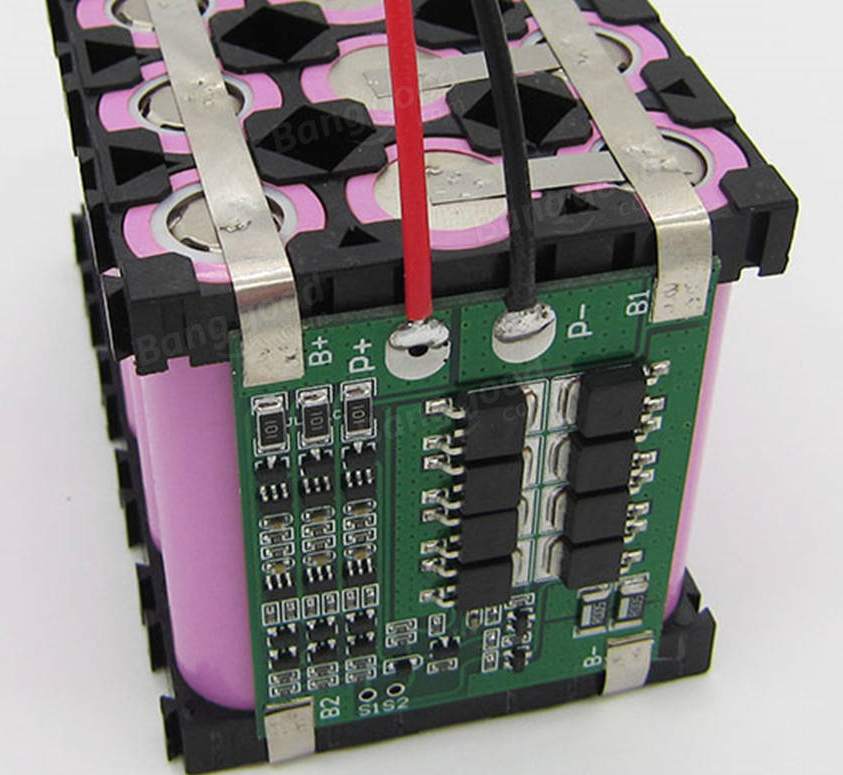

A Battery PCB (Printed Circuit Board) is a specialized PCB designed specifically for battery management systems (BMS) and battery pack assemblies. These PCBs play a crucial role in monitoring, protecting, and controlling the operation of rechargeable batteries used in various applications, such as electric vehicles, energy storage systems, and portable electronics. Here are some key points about Battery PCBs:

- Battery monitoring: Battery PCBs incorporate multiple sensing circuits to monitor critical parameters like cell voltage, temperature, and current. This information is used by the BMS to ensure safe and efficient battery operation.

- Cell balancing: Battery PCBs often include cell balancing circuits that help equalize the charge levels across individual cells within a battery pack, prolonging the overall battery life and improving performance.

- Protection circuits: Battery PCBs feature protection circuits that safeguard the battery from potential hazards, such as overcurrent, overcharging, deep discharge, and overheating. These circuits can disconnect the battery or trigger safety mechanisms when necessary.

- Power management: Battery PCBs may include power management circuits that regulate the charging and discharging processes, ensuring efficient energy transfer and optimal battery performance.

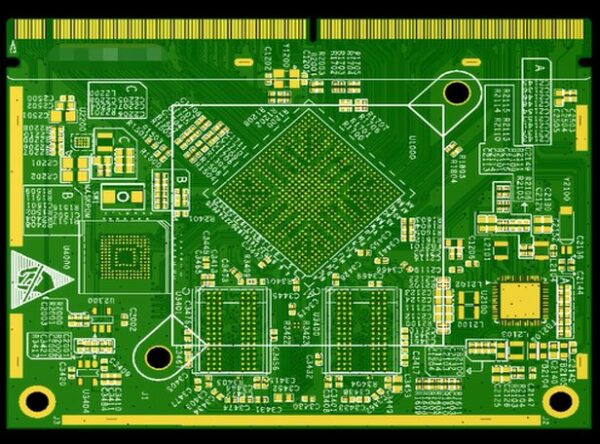

- Communication interfaces: Many Battery PCBs incorporate communication interfaces, such as CAN bus, I²C, or SPI, to enable communication between the BMS and other electronic control units or monitoring systems.

- High-temperature materials: Due to the potential for high operating temperatures in battery packs, Battery PCBs are often designed using high-temperature-resistant materials, such as polyimide or ceramic substrates, to ensure reliable operation and longevity.

- Compact design: Battery PCBs are typically designed to be compact and space-efficient, as they need to fit within the confined space of battery packs or battery modules.

- Safety certifications: Battery PCBs must comply with relevant safety standards and certifications, such as UL, IEC, or UN38.3, to ensure the safe operation and transportation of battery systems.

Battery PCBs are critical components in battery management systems, responsible for monitoring, protecting, and optimizing the performance of rechargeable battery packs. Their design and manufacturing require special considerations for high-temperature operation, safety, and reliability to meet the demanding requirements of various battery-powered applications.