Electronic Manufacturing Service

Global PCBA small and medium batch express service provider, We provide one-stop service, allowing electronic engineers to realize ideas faster and better

99.5%

Client retention

100% satisfy clients in our work

18+

Years of experience

Fully on Electronic Manufacturing

1000+

Clients

1000+ customers 6000+ Engineers

10K+

Projects

99% successfully all project done

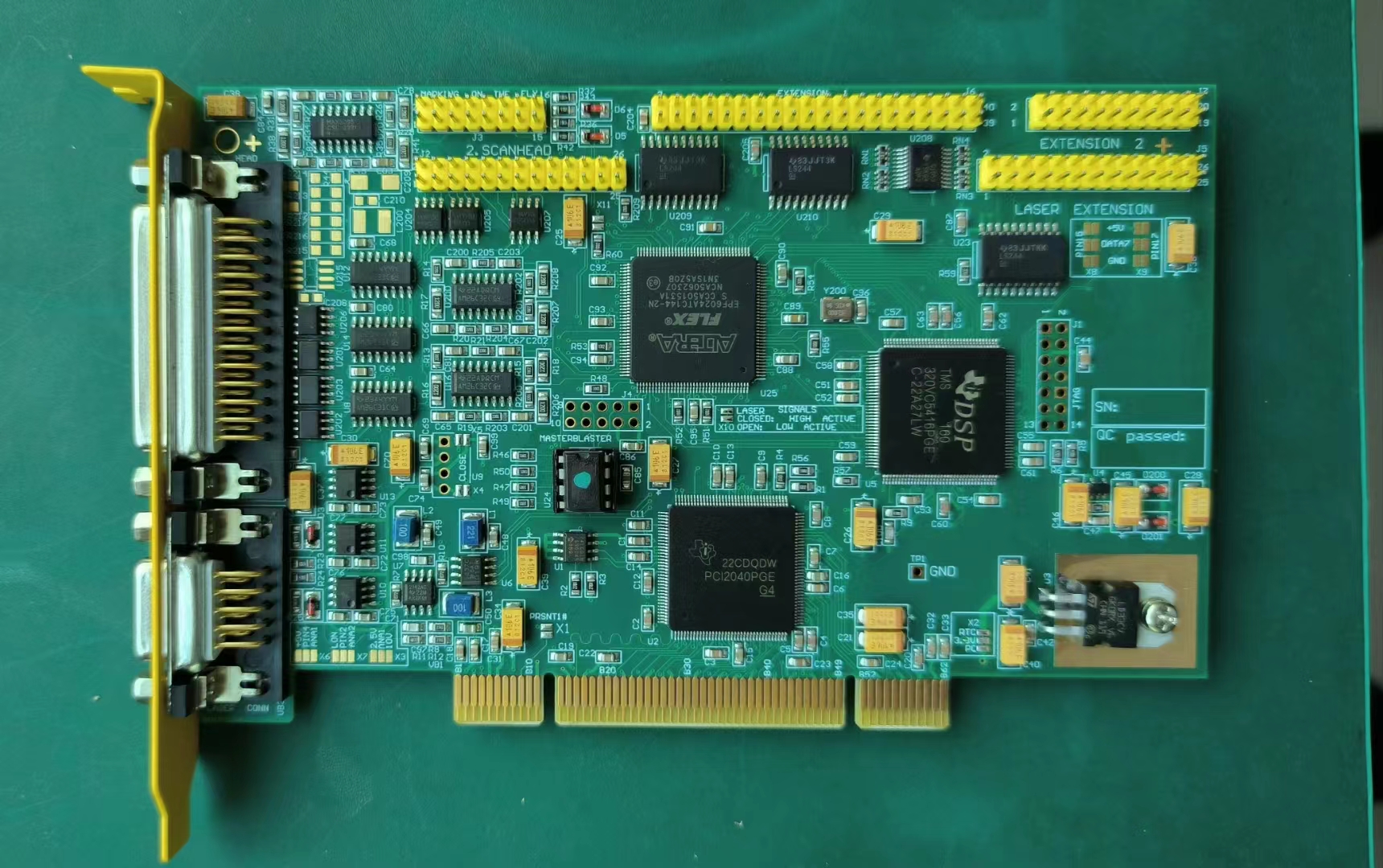

Electronic Manufacturing PROJECTS

Together We Will Drive Your Success

Our Services

Full Electronic Manufacturing Services

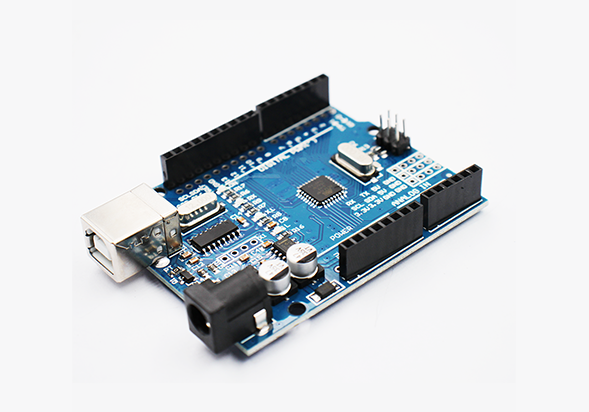

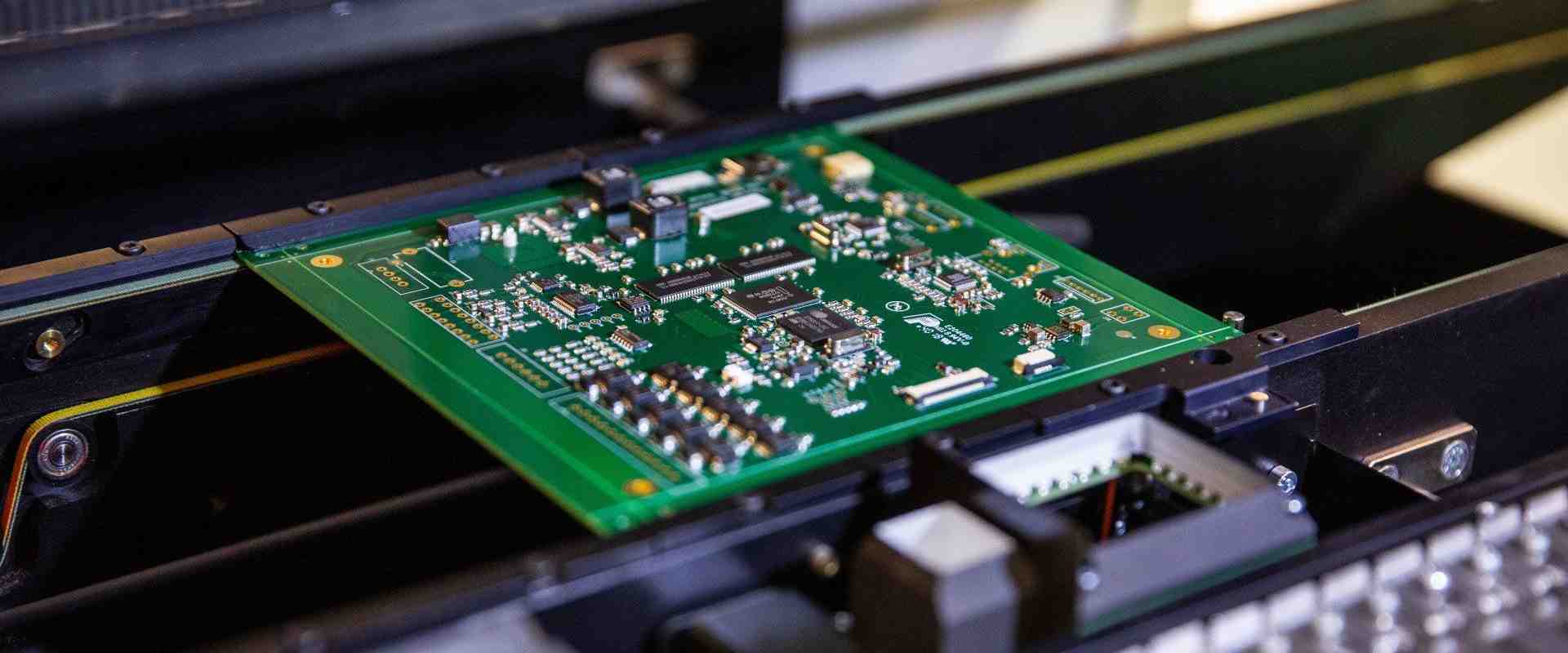

SMT ASSEMBLY

BGA\QFN package SMT processing

IC Programming

Online/Offline programming services

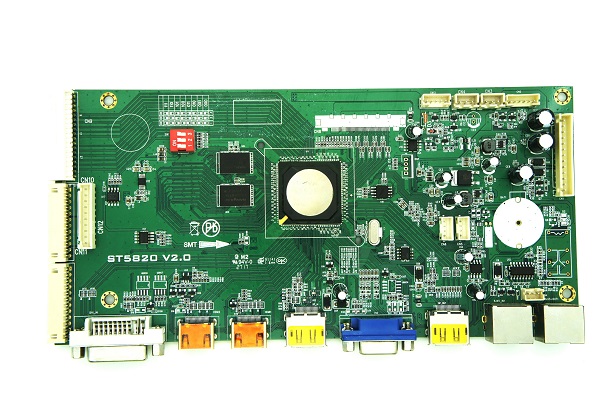

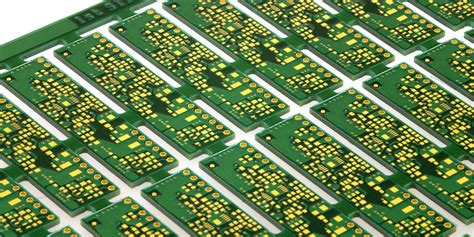

PCB MANUFACTURING

Rogers HDI Complext Board

PCBA Testing

Provide test solutions according to functional requirements

COMPONENTS SOURCING

Full/Partial Parts source

Box Building

Full Box Building Assembly

Six Guarantees

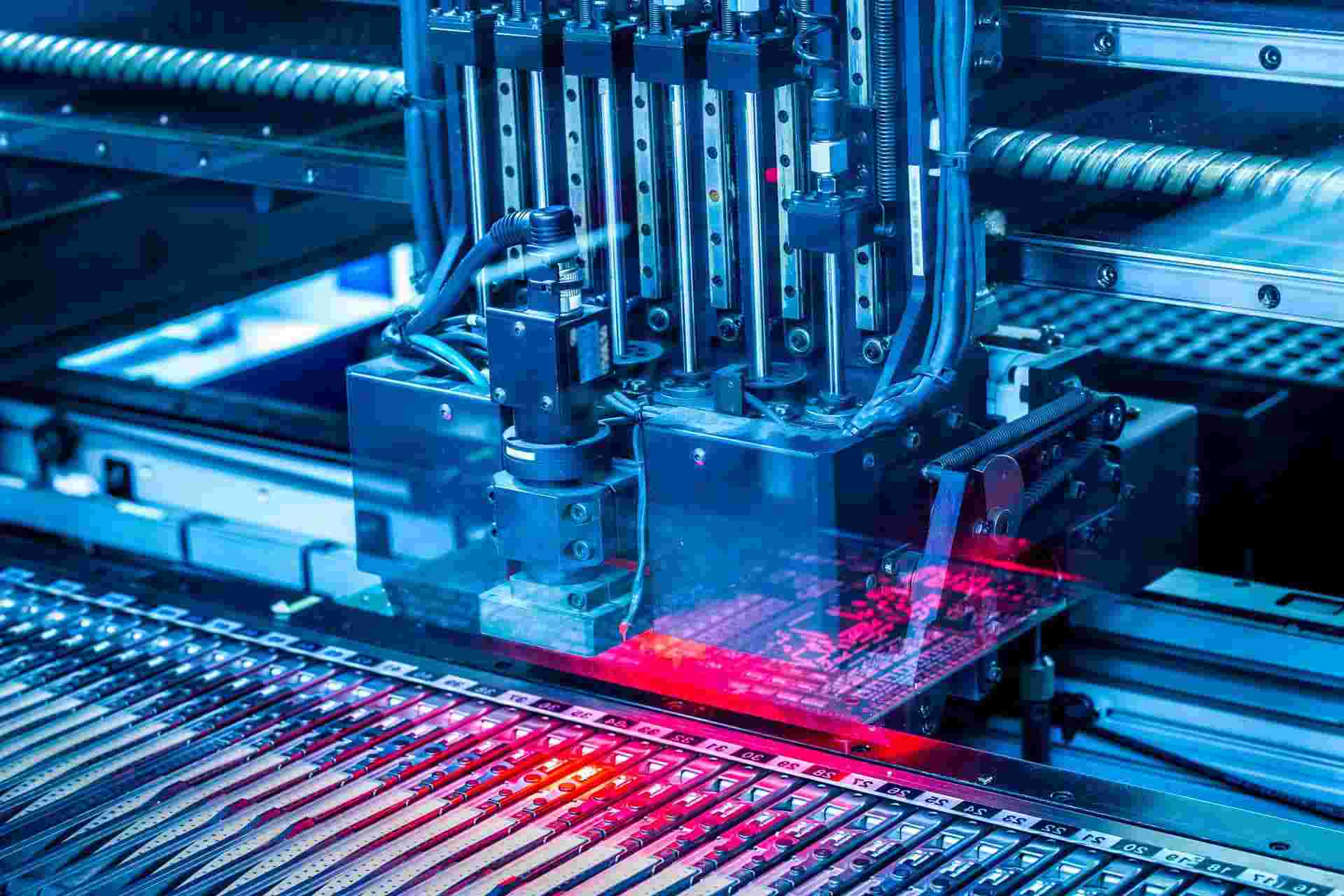

Fully automatic SMT production line, 9 testing procedures, the ultimate experience of quality

Raw material guarantee

Imported solder paste brand Alpha Innovative LCR incoming material inspection system keeps out refurbished components and selects high-quality raw materials

Fast Delivery Guarantee

12-hour expedited service, normal delivery within 3 days, 4-hour delivery, the first time to ensure the interests of customers

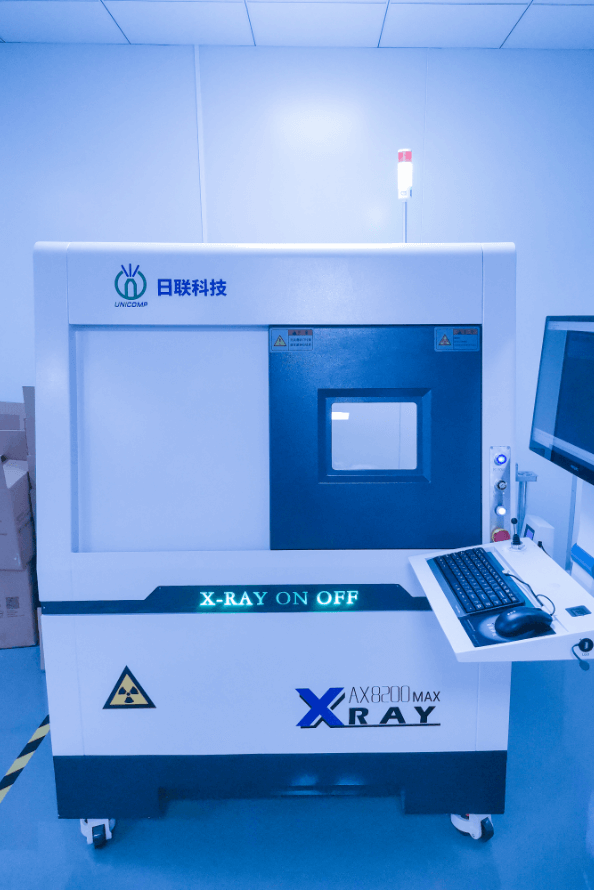

Product Quality Assurance

High-precision SMT equipment and perfect DIP production line, the introduction of ESD electrostatic system supplied, X-RAY inspection BGM quality is reliable and stable

R & D Support

Own R&D team,Using technological innovation to improve production efficiency and quality,Have rich process experience to prevent quality risks

Strength guarantee

Mature management team, enterprising spirit of innovation, self-developed MES system, first article test system, dedicated service to every customer

Customer Service

Professional technology and rich process experience

Provide a complete PCBA solution

Strive to bring customers the most perfect cooperation experience

Who We Are

Electronic Contract Manufacturer

We provide professional electronic products processing, chip processing, plug-in processing, OEM, ODM foundry services, located in the PCBA R & D and SMT, DIP, assembly of high-end electronic manufacturing service providers, mainly serving domestic and foreign high-end PCBA rapid prototyping, industrial industrial control automation, smart home, automotive networking, communications, medical and other high-end industry PCBA and finished products high-end manufacturing services, the company provides domestic and foreign customers with circuit board production, circuit board patch processing to patch test one-stop solution.

What We Do

Specialized Expertise

- We provide professional and attentive electronic information products processing \OEM\ODM manufacturing services:

- We provide professional SMT chip processing | DIP processing \OEM\ODM services for products covering consumer electronics, commercial electronics, industrial control electronics, health care electronics, communication electronics and other fields.

- Depending on the customer’s needs, we can provide PCBA processing or finished products.

- We have rich experience in manufacturing products with high process difficulty, such as BGA, QFN, double-row QFN, and double-layer BGA component products, and can give professional support to our customers.

- We can work with customers for samples and small orders.

Global One-stop Electronic Manufacturing Service Provider

Fast Prototype and Volume Production

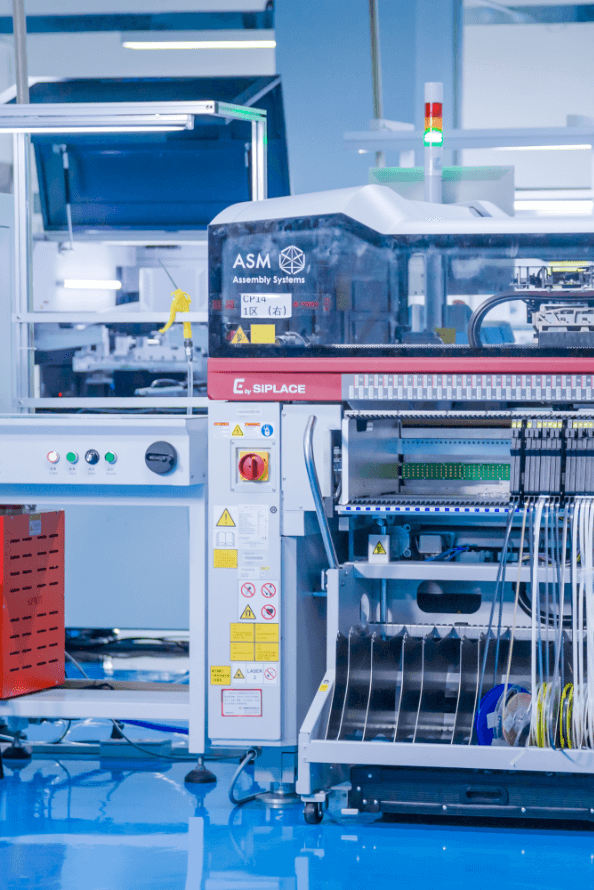

High Level Production Equipments

Advanced Technology Advanced Contract Manufacturing

Solder paste printing machine

GKG automatic printing machine

X-Ray

2D 3D X-Ray

SMT Machine

Brand new Siemens E series placement machine

Reflow Soldering

10-12 temperature zone air reflow soldering and nitrogen reflow soldering

From Our Blog Posts

All about electronic manufacturing – PCB Manufacturing,SMT Assembly, PCBA Test

-

Understanding the PCB Burn-in Testing Process in PCB Manufacturing!

What is PCB Burn-in Testing? PCB burn-in testing is a critical process in the manufacturing of printed circuit boards (PCBs) that involves subjecting the boards to elevated temperatures and voltages for an extended period. The purpose of this testing is to identify and eliminate early failures, ensuring that only reliable … Read more

-

Unlock the Potential of Embedded PCB Assemblies for Improving the Performance of Electronics Devices

What are Embedded PCB Assemblies? Embedded PCB assemblies, also known as embedded printed circuit boards, are a type of PCB design where electronic components are embedded within the layers of the board itself. This contrasts with conventional PCB designs, where components are mounted on the surface of the board. By … Read more

-

What are the Advantages of Custom Cable Assembly to meet your bespoke needs?

Understanding Custom Cable Assembly Before delving into the advantages of custom cable assembly, it is essential to understand what it entails. Custom cable assembly refers to the process of designing, manufacturing, and assembling cables and wire harnesses that are specifically tailored to meet the unique requirements of a particular application … Read more

Together We Will Drive Your Success

INDUSTRIES WE SERVE

High-end manufacturing service provider of industrial control industry, smart home, communication medical PCBA.

Security Industry

Security industry products include monitoring, burglar alarms, intrusion detectors, burglar alarm controllers, car alarm systems, electronic fences, etc.

Automotive Electronics

Window control panels, airbag systems, driving dynamics regulation (FDR or VDC), collision avoidance systems, seatbelt control, photo control

IOT Devices

Alcohol Detection for Bus Drivers, Agricultural Irrigation, Oil Pipeline Control, Blood Pressure Monitoring, Industrial Inspection, Gas Detection

Industrial control signals

With embedded industrial controllers and PLCs, robots, servo motors, sensors, industrial cameras, PLC programmable logic controllers

Medical Electronics

Sphygmomanometer, electronic thermometer, multifunctional therapeutic instrument, blood glucose meter, electric massage chair/bed, massage stick; massage whack; massage pillow, massage cushion, massage belt; qi and blood circulation machines; foot baths

Communications Electronics

5G Base Station, 4G Base Station, Logistics Handheld Devices, Face Recognition Devices,

Intelligent Home

Smart Door Lock, Smart Curtain, Smart Lighting, Smart Speaker, Mop-Sweep Robot, Smart Pet Feeder, Smart Pet Feeder, Smart Stir-Fryer, Smart Toilet

Military Electronics

Radar, microwave monolithic integrated circuits, laser rangefinders, night vision devices, as well as laser sights, communications, electronic countermeasures, TR components, phased array antennas

Smart Wearable

VR/AR, Smartwatch

Artist 3D, Make electronic innovation easier!

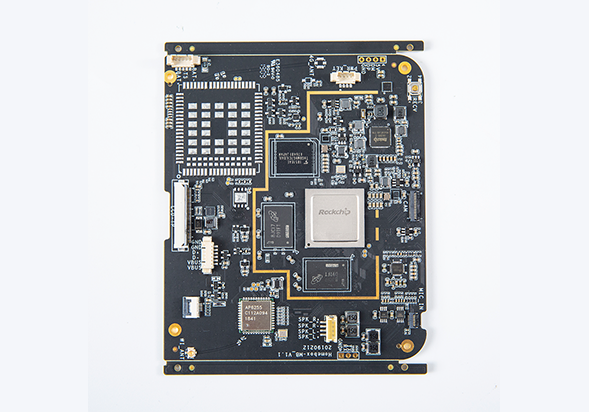

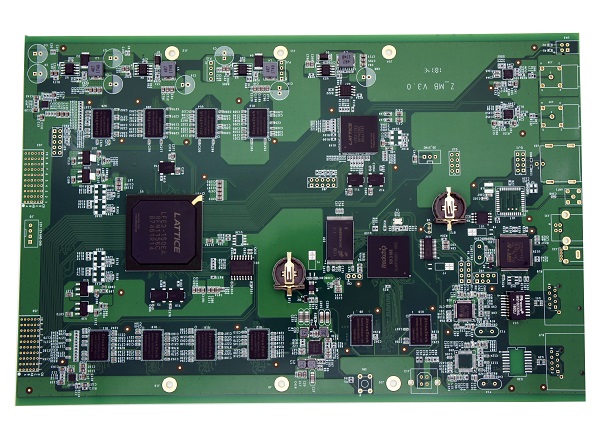

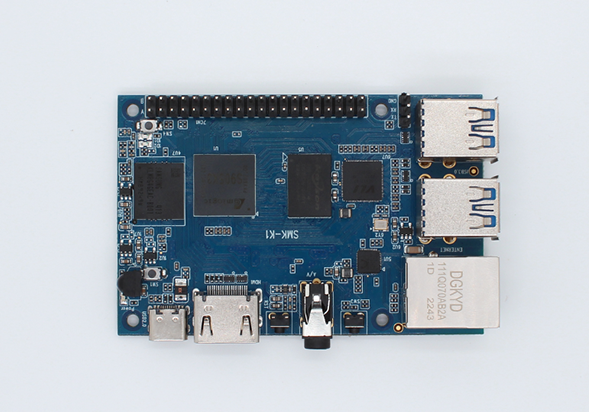

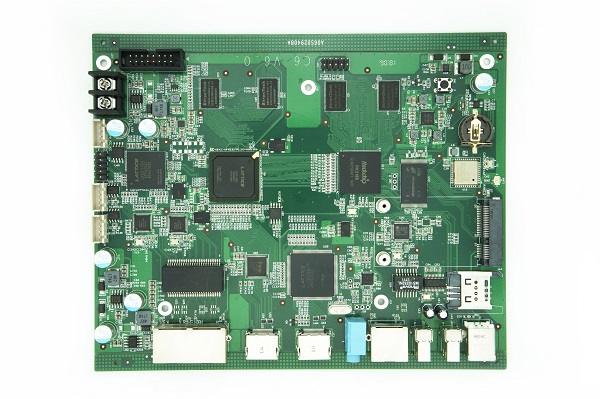

Watch Phone Board

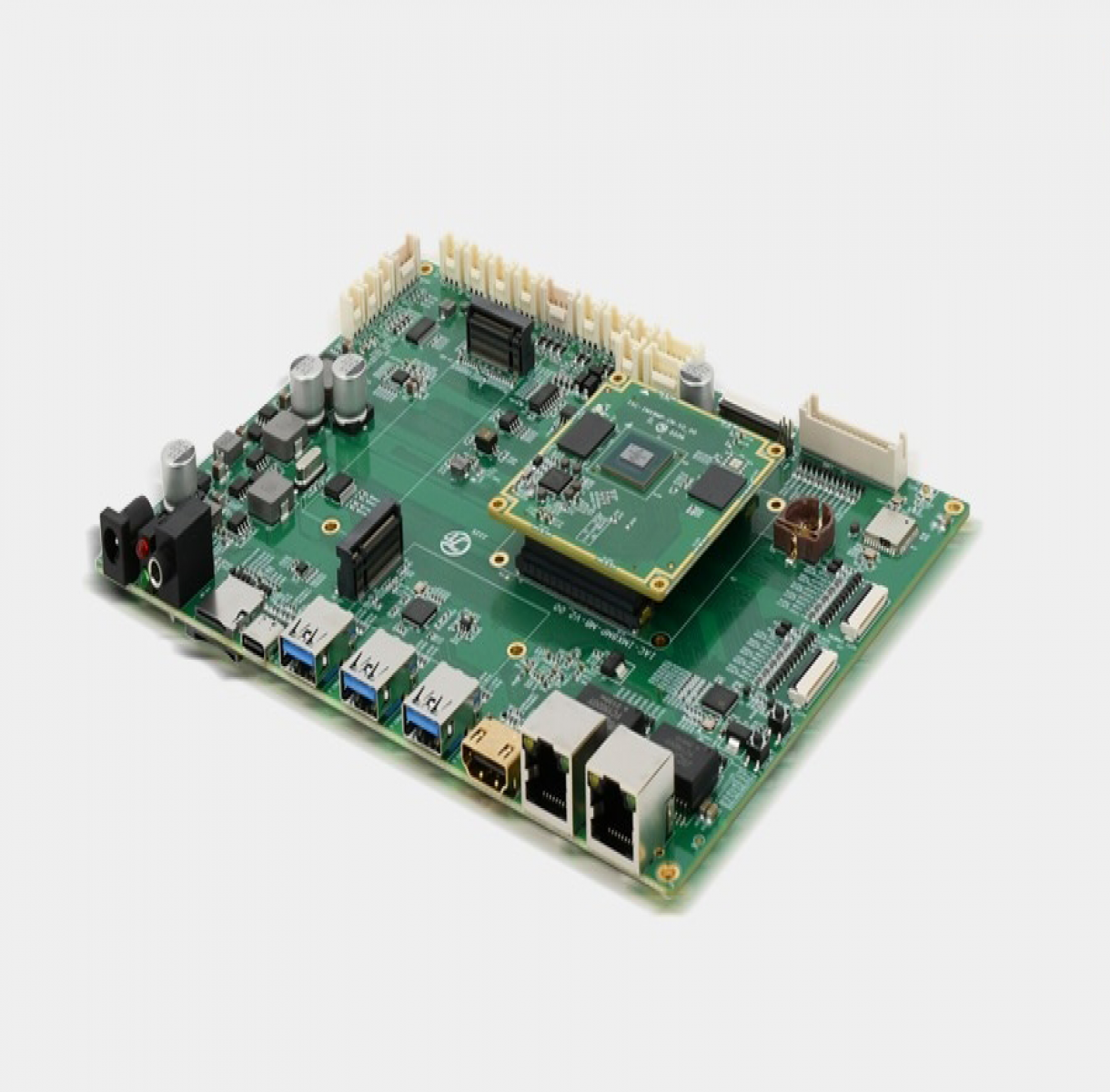

IAC-IMX8MP-Kit Development Board

3D Printer Main Board

Technical Capability

Global PCBA small and medium batch fast production service provider

SMT

SMD DIP

- Size:L50*w50~L510*w460mm

- Thickness:0.3mm~4.5mm

- Material:Rigid, Polymide,Rigid-flex

- Part Size:01005 ~ 45mm*98mm

- Part Pitch:IC 0.25mm,BGA-0.25mm

- Part Height:19mm

- SMT precision:chip±41μm,IC±37.5μm

- SMT capacity:1000万/D

PCB

Rigid RF HDI Board

- Layer:56

- PCB Thickness:7.0mm

- Min Thickness:0.33mm(4 Layer)

- Min width/spacing:3/3mil

- Copper Thickness:0.5 – 20oz

- Aspect ratio: 10:1

- Hole Tolerance: +/-0.05mm

- PTH Bore Tolerance: +/-0.05mm

- HDI steps: 4+N+4

Components

IC FPGA

- Original Agent Supply Chain

- Strategic Cooperation Big Data Platform

- Rapid delivery

- More than 30,000 commonly used components in stock

- Experienced supply chain team

- Full BOM component Sourcing

- Fast component system, 24H quotation support