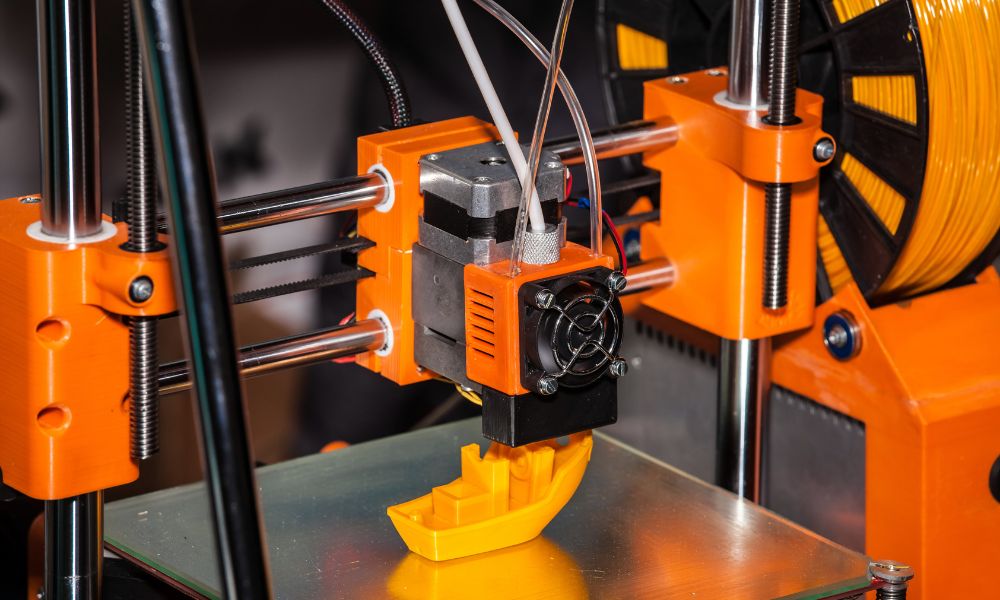

3D printing has revolutionized the world of manufacturing, allowing designers and engineers to create complex and intricate designs with ease. But what exactly can a 3D printer make? The possibilities are virtually endless, ranging from simple household items to advanced medical implants.

One of the most popular uses for 3D printers is prototyping. Designers and engineers can quickly create physical models of their digital designs and make modifications on the fly. This allows for a more efficient design process and can save time and money in the long run. But 3D printing isn’t just limited to prototyping – it can also be used to create final products. With advancements in materials and technology, 3D-printed products are becoming increasingly common in industries such as automotive, aerospace, and consumer goods.

In addition to industrial applications, 3D printing has also made its way into the world of art and design. Artists can use 3D printers to create intricate sculptures and installations, while designers can create custom jewelry and accessories. And for the DIY enthusiasts, 3D printers can be used to create everything from replacement parts for household appliances to toys and games for children. With the ability to create custom designs and prototypes quickly and easily, 3D printing is changing the way we approach manufacturing and design.

Functional Objects

3D printing is not only about creating toys and figurines, but it can also produce functional objects that can be used in our daily lives. Here are some of the functional objects that can be printed using a 3D printer.

Household Items

One of the most common uses of 3D printing is to create household items. These items can range from simple objects like keychains and phone cases to more complex items like furniture and home decor. 3D printing allows for customization and personalization of these household items, making them unique and tailored to the user’s needs. Some examples of household items that can be printed include:

- Planters and vases

- Utensil holders and kitchen gadgets

- Doorstops and hooks

- Light switch covers and outlet covers

Tools

3D printing has made it possible to create custom tools that are specific to certain tasks. These tools can be printed quickly and easily, and they can be customized to fit the user’s needs. 3D printed tools can also be used as prototypes before creating the final product. Some examples of 3D printed tools include:

- Screwdrivers and wrenches

- Clamps and jigs

- Drill guides and measuring tools

- Phone and tablet stands

Medical Devices

3D printing has also made it possible to create medical devices that are tailored to the patient’s needs. These devices can be printed quickly and at a lower cost than traditional manufacturing methods. 3D printing also allows for customization and personalization of medical devices, making them more comfortable and effective for the patient. Some examples of 3D printed medical devices include:

- Prosthetic limbs and braces

- Hearing aids and dental implants

- Surgical instruments and guides

- Customized pill boxes and medication dispensers

In conclusion, 3D printing has opened up a world of possibilities for creating functional objects that can be used in our daily lives. From household items to medical devices, the customization and personalization capabilities of 3D printing make it a valuable tool for creating objects that are tailored to our specific needs.

Artistic Creations

3D printing technology has opened up a whole new world of possibilities for artists and designers. With the ability to create intricate and complex shapes, 3D printers have revolutionized the way we think about art and design. Here are some of the most popular artistic creations that can be made using a 3D printer.

Sculptures

Sculptures are one of the most popular artistic creations that can be made using a 3D printer. The ability to create complex shapes and designs in a variety of materials has made 3D printing an ideal tool for sculptors. With a 3D printer, artists can create sculptures that are impossible to make using traditional methods.

Jewelry

3D printing has also revolutionized the jewelry industry. With the ability to create intricate and complex designs, 3D printers have made it possible for designers to create jewelry that was previously impossible to make. 3D printing allows designers to create custom pieces that are unique and personalized.

Models

3D printing is also commonly used to create models for various industries. Architects, engineers, and product designers use 3D printers to create models of their designs, allowing them to test and refine their ideas before they are put into production. 3D printing has made it easier and more affordable to create accurate and detailed models, making it an essential tool for many industries.

In conclusion, 3D printing has opened up a whole new world of possibilities for artists and designers. With the ability to create intricate and complex shapes, 3D printers have revolutionized the way we think about art and design. From sculptures to jewelry to models, 3D printing has made it possible to create things that were previously impossible to make.

Engineering Components

3D printing has revolutionized the way engineers design and manufacture components. With 3D printing, it is possible to create complex designs and geometries that would be difficult or impossible to produce using traditional manufacturing techniques. Here are some of the engineering components that can be made using a 3D printer.

Aerospace Parts

Aerospace is one of the industries that has benefited the most from 3D printing technology. The ability to create lightweight, complex parts has made it possible to reduce the weight of aircraft and spacecraft, which in turn improves fuel efficiency and performance. Some of the aerospace parts that can be 3D printed include:

- Engine components

- Turbine blades

- Heat exchangers

- Structural parts

In addition to reducing weight, 3D printing can also reduce the time and cost of manufacturing aerospace components. With traditional manufacturing techniques, a single part may require multiple steps and several different machines. With 3D printing, the entire part can be printed in a single step, reducing the time and cost of production.

Automotive Parts

Like aerospace, the automotive industry has also benefited from 3D printing technology. One of the main advantages of 3D printing in the automotive industry is the ability to create customized parts. With 3D printing, it is possible to create parts that are tailored to the specific needs of a vehicle, which can improve performance and reduce weight. Some of the automotive parts that can be 3D printed include:

- Engine components

- Exhaust manifolds

- Suspension components

- Brake calipers

In addition to customization, 3D printing can also reduce the time and cost of producing automotive components. With traditional manufacturing techniques, creating a new part can take weeks or even months. With 3D printing, a new part can be printed in a matter of hours.

Robotics Components

Robots are used in a wide range of industries, from manufacturing to healthcare. 3D printing has made it possible to create custom components for robots that can improve their performance and functionality. Some of the robotics components that can be 3D printed include:

- Grippers

- Joints

- End effectors

- Frames

With 3D printing, it is possible to create complex geometries that are difficult or impossible to produce using traditional manufacturing techniques. This can improve the performance and functionality of robots, making them more efficient and effective.

In conclusion, 3D printing has opened up new possibilities for engineers in a wide range of industries. With the ability to create custom, complex parts quickly and cost-effectively, 3D printing is transforming the way we design and manufacture engineering components.

Food

3D printing has revolutionized the way we think about food. With a food 3D printer, you can create intricate designs and shapes that would be impossible to create by hand. Here are a few examples of what you can make with a 3D printer:

Chocolate

3D printing has made it possible to create intricate chocolate designs that would be impossible to make by hand. With a food 3D printer, you can create chocolate sculptures, intricate designs, and even personalized chocolate bars with your name on them. Some food 3D printers even allow you to print with multiple types of chocolate, creating unique flavor combinations.

Pizza

Pizza is a staple food for many people, and 3D printing has made it possible to create unique and customized pizzas. With a food 3D printer, you can create pizzas in any shape or size, and even print toppings in intricate designs. Some food 3D printers even allow you to print with multiple types of dough, creating unique flavor combinations.

Pasta

3D printing has made it possible to create intricate pasta designs that would be impossible to make by hand. With a food 3D printer, you can create pasta in any shape or size, and even print personalized messages or designs onto the pasta. Some food 3D printers even allow you to print with multiple types of pasta dough, creating unique flavor combinations.

Overall, 3D printing has opened up a whole new world of possibilities when it comes to food. With a food 3D printer, you can create unique and customized designs that would be impossible to create by hand. Whether you’re a professional chef or just a food lover, a food 3D printer is a great tool to have in your kitchen.

Conclusion

In conclusion, 3D printing is a revolutionary technology that has the potential to change the way we manufacture products. With the ability to create complex and intricate designs, 3D printing has opened up new possibilities for product development and customization.

One of the advantages of 3D printing is its flexibility in materials. 3D printers can use a wide range of materials, such as plastics, metals, and even food. This allows for the creation of a variety of products, from toys to prosthetics to aerospace parts.

Another benefit of 3D printing is its cost-effectiveness for small-scale production. As 3D printers become more affordable, they will inevitably be used for local, small scale manufacturing, largely eliminating supply chains for many types of product. Consumer units for home use will even become feasible, allowing end users to simply download a design for the product they require and print it out.

However, there are also limitations to 3D printing technology. One of the most significant limitations is the size of the objects that can be printed. Most consumer-grade 3D printers have a limited build volume, which restricts the size of the objects that can be printed. Additionally, the time it takes to print an object can be lengthy, depending on the complexity and size of the object.

Overall, 3D printing is a promising technology that has already made significant strides in the manufacturing industry. While there are limitations to the technology, the potential for customization, cost-effectiveness, and flexibility in materials make it a valuable tool for product development and manufacturing.

Resouces:

https://www.pcmag.com/news/3d-printing-what-you-need-to-know

https://all3dp.com/1/useful-cool-things-3d-print-ideas-3d-printer-projects-stuff/

https://techjury.net/blog/what-can-you-make-with-a-3d-printer/#gref

https://www.easyrhino3d.com/100-useful-things-you-can-make-with-a-3d-printer/